Industrial robot geometric parameter identification method based on transformation matrix error model

An industrial robot and transformation matrix technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of production line production capacity and efficiency, and achieve the goal of improving end positioning accuracy, measurement accuracy, and efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

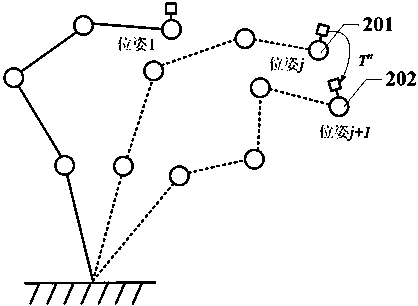

[0036] The present invention is described in further detail now in conjunction with accompanying drawing.

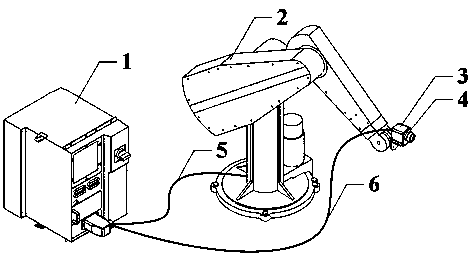

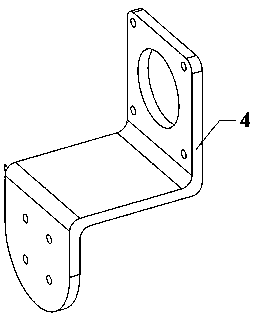

[0037] Such as figure 1 and figure 2 As shown, a method for identifying geometric parameters of an industrial robot based on a transformation matrix error model. The structure of an industrial robot includes a robot control cabinet 1, an industrial robot 2, an intelligent industrial camera 3, a camera mounting frame 4, a control signal communication cable 5 and a transmission signal communication Cable 6, the intelligent industrial camera 3 is fixedly installed at the end of the industrial robot 2 through the camera mounting frame 4, the industrial robot 2 is connected to the robot control cabinet 1 through the control signal communication cable 5, and the intelligent industrial camera 3 It is connected with the robot control cabinet 1 through the signal transmission communication cable 6 .

[0038] In this embodiment, a processor capable of processing and sending sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com