Tail end error correction system for three-degree-of-freedom parallel robot and tail end error correction method

A technology of error correction and correction method, which is applied in the field of robotics, can solve the problems of limiting the application range of error correction methods, etc., and achieve the effect of easy-to-use terminal error correction system and method, improve terminal positioning accuracy, and avoid disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]In order to further explain the purpose, technical solutions and advantages of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

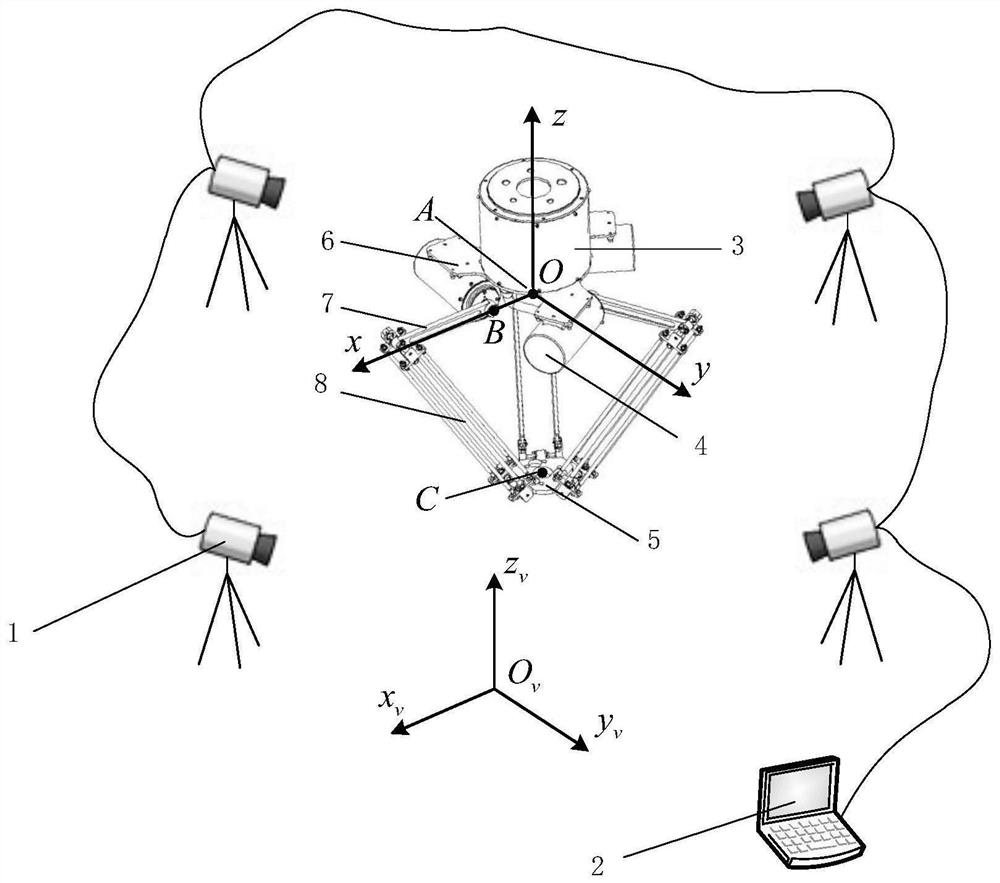

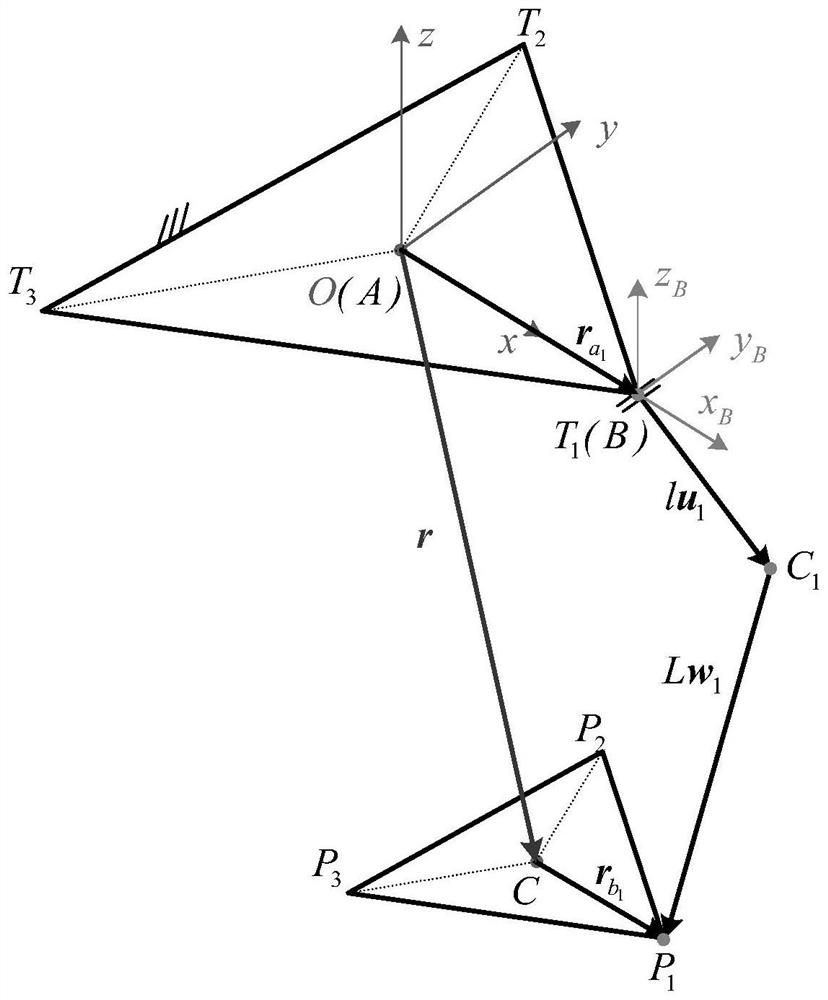

[0047] Such as figure 1 As shown, the three-degree-of-freedom parallel robot consists of an electronic cabin 3, a dynamic platform 5, a static platform 6, and three symmetrically arranged branch chains (also called "parallel mechanisms"), each of which contains a Arm steering gear 4, master arm 7 and slave arm 8.

[0048] When the parallel robot moves, the three active arms connected to it are driven by the three arm servos to rotate, and then the three slave arms are driven to move, so that the moving platform 5 produces translation in three-dimensional space. The motion space of the moving platform is a cylinder space.

[0049] The visual positioning camera 1 adopts a CCD camera with an infrared light source, and the passive reflective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com