Static blasting construction method for highway tunnel

A static blasting, highway tunnel technology, applied in blasting and other directions, can solve the problems of increased construction cost, poor construction safety, low rock-breaking capacity, etc., and achieve the effect of reducing project cost, safe and reliable construction, and high rock-breaking efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Below in conjunction with a specific construction case of a tunnel and accompanying drawing, the present invention is described in further detail:

[0040] A static blasting construction method for high ground stress soft rock road tunnels, the steps of which are:

[0041] 1. Formulate tunnel excavation methods:

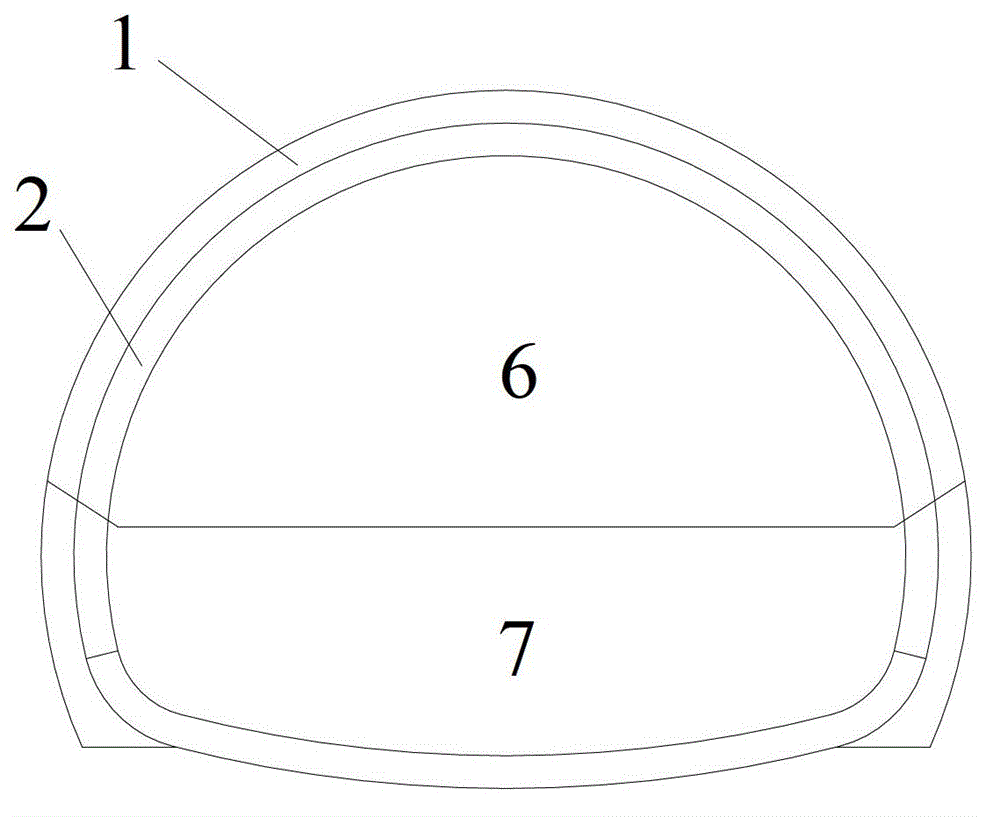

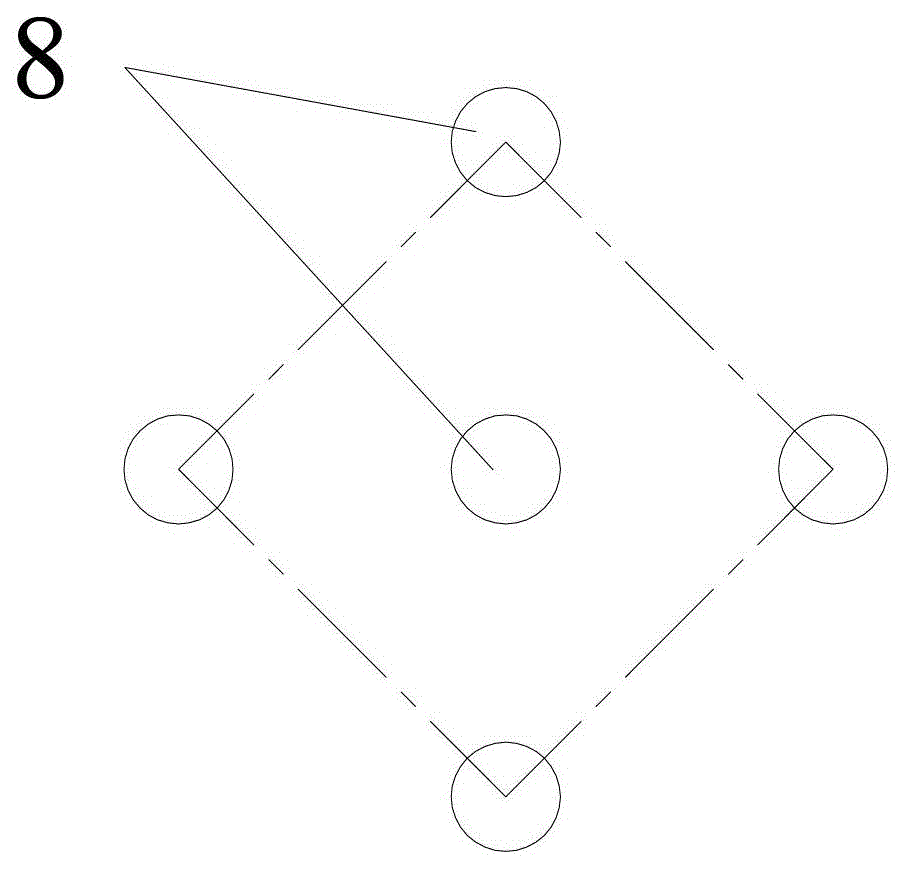

[0042] Tunnel cavity type and support type such as figure 1 , figure 2 Shown (1 is the primary lining of the tunnel, 2 is the secondary lining of the tunnel).

[0043] Different tunnel excavation methods are adopted according to the type of surrounding rock. When the surrounding rock is grade V (the classification of surrounding rock is based on "Code for Design of Highway Tunnels JTG D70-2004"), the three-step method (see figure 1 ) excavation, the heights of upper bench 3, middle bench 4, and lower bench 5 are respectively 3.5m, 3.5m, and 5.0m, and each cycle footage is taken as 1.5m. The height of bench excavation and cycle footage should be adjusted a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com