Anti-slip partially-encased type combined beam and prefabrication method thereof

A technology of anti-slip and composite beams, applied in the direction of manufacturing tools, structural elements, building components, etc., can solve the problems of broken steel bars in beams, beam stiffness, and weakened bearing capacity, so as to facilitate design and construction, increase strength and The deformation ability and the effect of shortening the project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

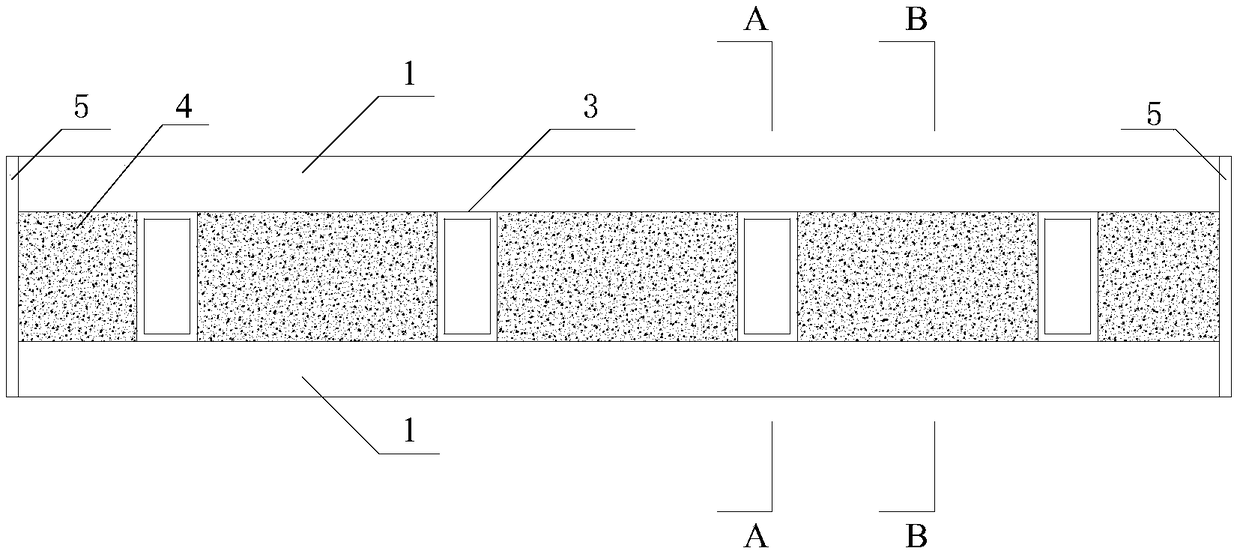

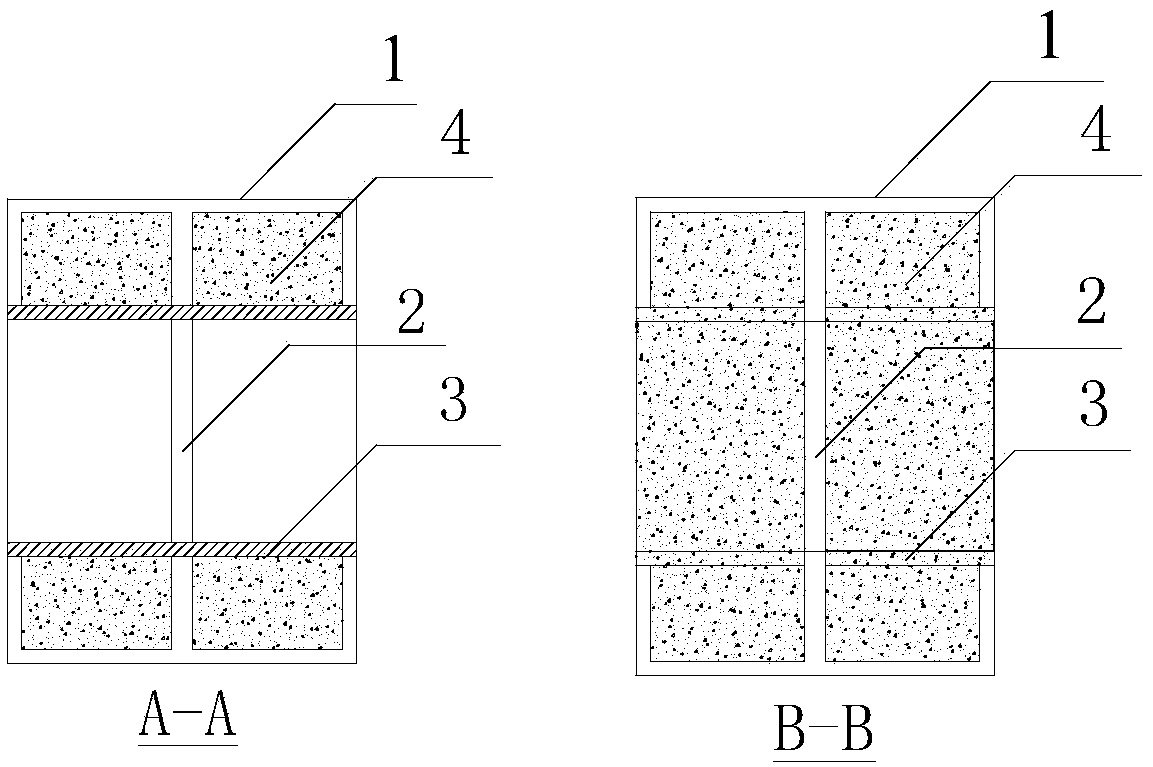

[0028] Such as Figure 1~3 As shown, an anti-slip composite beam is partly outsourced, including channel steel 1, steel plate with holes 2, square steel pipe 3, inner filling concrete 4, and end steel plates 5; the upper and lower sides of the steel plate 2 with holes are respectively connected with A channel steel 1 is connected by welding, square steel pipe 3 passes through the hole of steel plate 2 with holes, and is welded on the hole, the two ends of channel steel 1 are welded with end steel plates 5; channel steel 1, steel plate 2 with holes, square steel pipe 3. Concrete 4 is filled in the steel skeleton of the beam member formed with the end steel plates 5.

[0029] The holes of the steel plate 2 with holes are attached to the outer surface of the square steel pipe 3, and after welding, there is no gap between the square steel pipe 3 and the holes of the steel plate 2 with holes. The channel steel 1 connected to the upper and lower sides of the steel plate 2 with hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com