Cement-based wave absorbing plate of three-layer structure mixed with EP and NGPs wave absorbing agent and preparation method of wave absorbing plate

A three-layer structure, cement-based technology, applied in the direction of building construction, construction, etc., can solve the problems of low tensile strength, low bending strength, poor electrical conductivity and microwave absorption, etc., and achieve the effect of simple preparation process and convenient molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

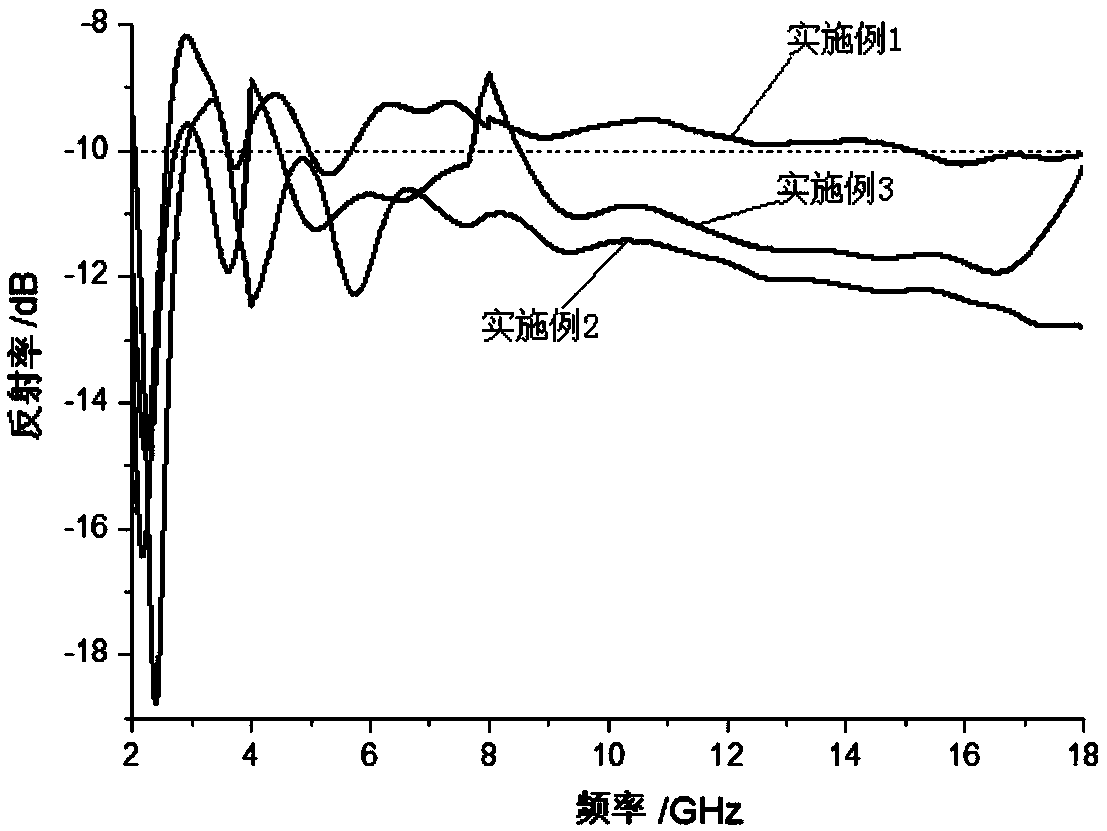

Embodiment 1

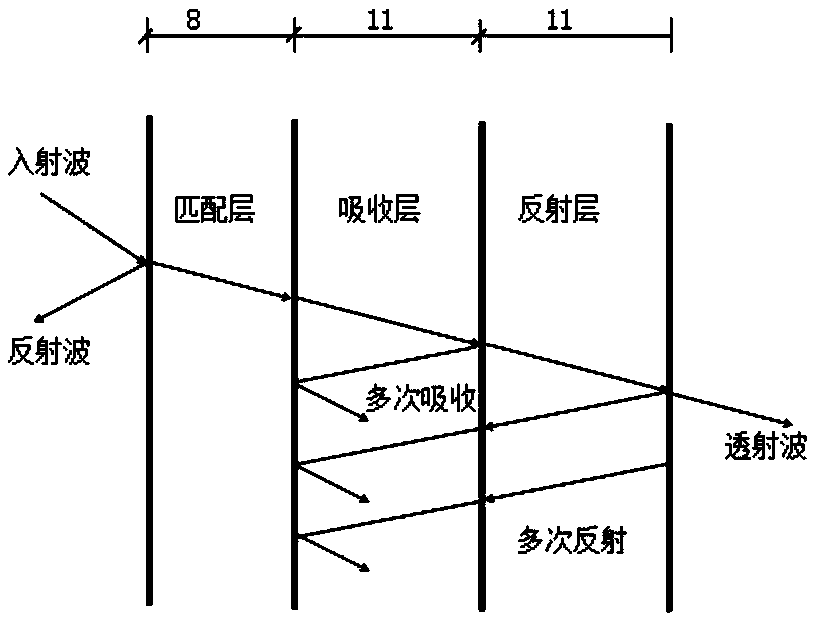

[0039] A three-layer structure cement-based wave-absorbing board compounded with EP and NGPs wave-absorbing agents, consisting of an upper layer, a middle layer and a lower layer, the thicknesses of the upper layer, middle layer and lower layer are 8mm, 11mm and 11mm respectively;

[0040] Wherein, the upper plate includes cement, silica fume, expanded perlite and water reducer, and the silica fume, water, expanded perlite and water reducer account for 10%, 42%, 7% and 0.32% of the cement mass respectively;

[0041] The middle plate includes cement, silica fume, water, multilayer graphene nanosheets, nano-nickel particles and water reducer, and the silica fume, water, multilayer graphene nanosheets, nanometer nickel particles and water reducer respectively account for 10%, 33%, 0.025%, 0.7%, 0.33% of

[0042] The lower plate comprises cement, silica fume, water, carbon fiber, carbon black, water reducer and dispersant; said silica fume, water, carbon fiber, carbon black, water...

Embodiment 2

[0050] A three-layer structure cement-based wave-absorbing board compounded with EP and NGPs wave-absorbing agents, consisting of an upper layer, a middle layer and a lower layer, the thicknesses of the upper layer, middle layer and lower layer are 8mm, 11mm and 11mm respectively;

[0051] Wherein, the upper plate includes cement, silica fume, expanded perlite and water reducer, and the silica fume, water, expanded perlite and water reducer account for 10%, 42%, 7% and 0.32% of the cement mass respectively;

[0052] The middle plate includes cement, silica fume, water, multilayer graphene nanosheets, nano-nickel particles and water reducer, and the silica fume, water, multilayer graphene nanosheets, nanometer nickel particles and water reducer respectively account for 10%, 32%, 0.025%, 0.7%, 0.33%;

[0053] The lower plate includes cement, silica fume, water, carbon fiber, carbon black, water reducer and dispersant; the silica fume, water, carbon fiber, carbon black, water red...

Embodiment 3

[0061] A three-layer structure cement-based wave-absorbing board compounded with EP and NGPs wave-absorbing agents, consisting of an upper layer, a middle layer and a lower layer, the thicknesses of the upper layer, middle layer and lower layer are 8mm, 11mm and 11mm respectively;

[0062] Wherein, the upper plate includes cement, silica fume, expanded perlite and water reducer, and the silica fume, water, expanded perlite and water reducer account for 10%, 42%, 7% and 0.32% of the cement mass respectively;

[0063] The middle plate includes cement, silica fume, water, multilayer graphene nanosheets, nano-nickel particles and water reducer, and the silica fume, water, multilayer graphene nanosheets, nanometer nickel particles and water reducer respectively account for 10%, 33%, 0.05%, 0.7%, 0.35% of

[0064] The lower plate includes cement, silica fume, water, carbon fiber, carbon black, water reducer and dispersant; the silica fume, water, carbon fiber, carbon black, water re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Minimum reflectivity | aaaaa | aaaaa |

| Effective bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com