Cable tension uniformity monitoring system for parallel steel strand stay cable and construction method thereof

A technology of parallel steel strand and monitoring system, applied in tension measurement, bridge parts, erection/assembly of bridges, etc., can solve problems such as beam deformation and uneven force, achieve high work efficiency, low labor cost input, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

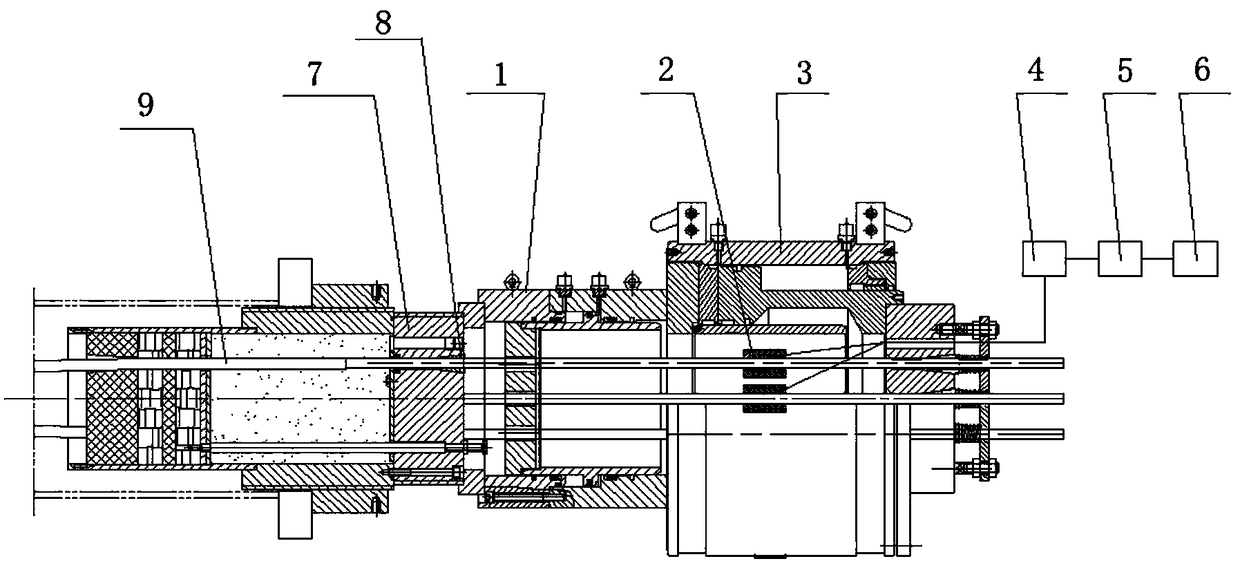

[0018] Such as figure 1 As shown, the cable force uniformity monitoring system for parallel steel strand cable-stayed cable construction is characterized in that it includes a working anchor plate 7, a working clip 8, a top pressure jack 1, a magnetic flux sensor 2, a tension jack 3, and a multi-channel switch Box 4, magnetometer 5 and host computer 6; the working anchor plate 7 is worn on the steel strand stay cable 9, the working clip 8 is located on the working anchor plate 7, and the working anchor plate 7 and the working clip 8 are used It is used to fix the stay cable 9 of the steel strand; the jack 1 is installed on the rear end of the working anchor plate 7, and is used to tighten the working clip 8 after the tensioning is completed; the tensioning jack 3 is installed on the jack The rear end of the jack 1 is used for the overall tensioning of the steel strand stay cables 9; the magnetic flux sensor 2 is installed on the steel strand stay cables 9 between the top press...

Embodiment approach 2

[0020] Embodiment 2 is a further optimization of Embodiment 1. The magnetoelastic instrument used has an operating platform and an LCD display for direct reading.

Embodiment approach 3

[0022] The method for carrying out construction using the cable force uniformity monitoring system for cable-stayed cable construction with parallel steel strands comprises the following steps: Step 1, installation of the cable force uniformity monitoring system for cable-stayed cable construction with parallel steel strands; Determine the 0-100% F graded tensioning process of steel strand stay cables 9, start tensioning jacks 3 pairs of parallel steel strand stay cables 9 overall graded tensioning; step 3, after each level of tension cable force is loaded, During the pressure holding time, the host computer 6 controls the multi-channel switch box 4 to switch the monitoring channel to monitor each magnetic flux sensor 2, and uses the monitored cable force value of each steel strand stay cable 9 as the tension control force value , and record the cable force value of each steel strand stay cable 9; step 4, the upper computer 6 reads the cable force value monitored by the magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com