Automatic cloth dyeing machine

A cloth dyeing machine and automatic technology, applied in the field of cloth dyeing, can solve the problems of low technical efficiency and great harm to human body, and achieve the effects of ensuring the quality of dyeing cloth, improving the dyeing rate and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention is described further as follows:

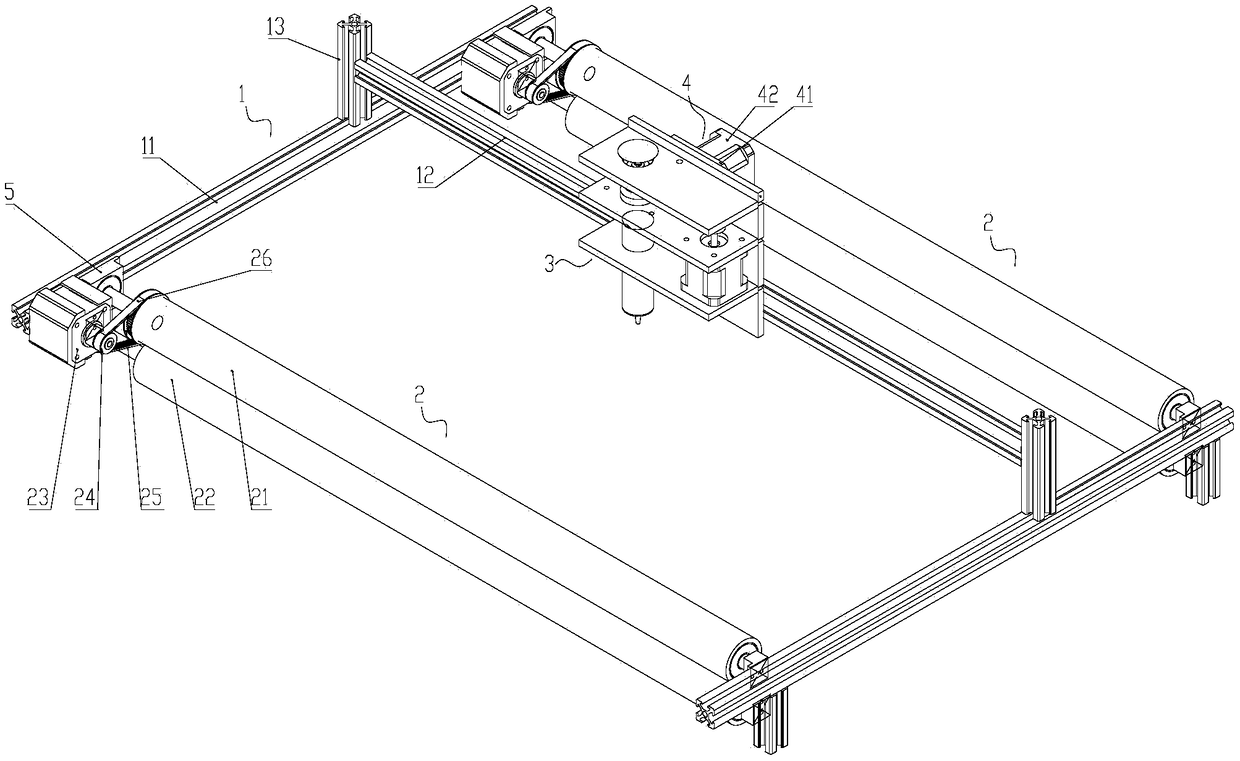

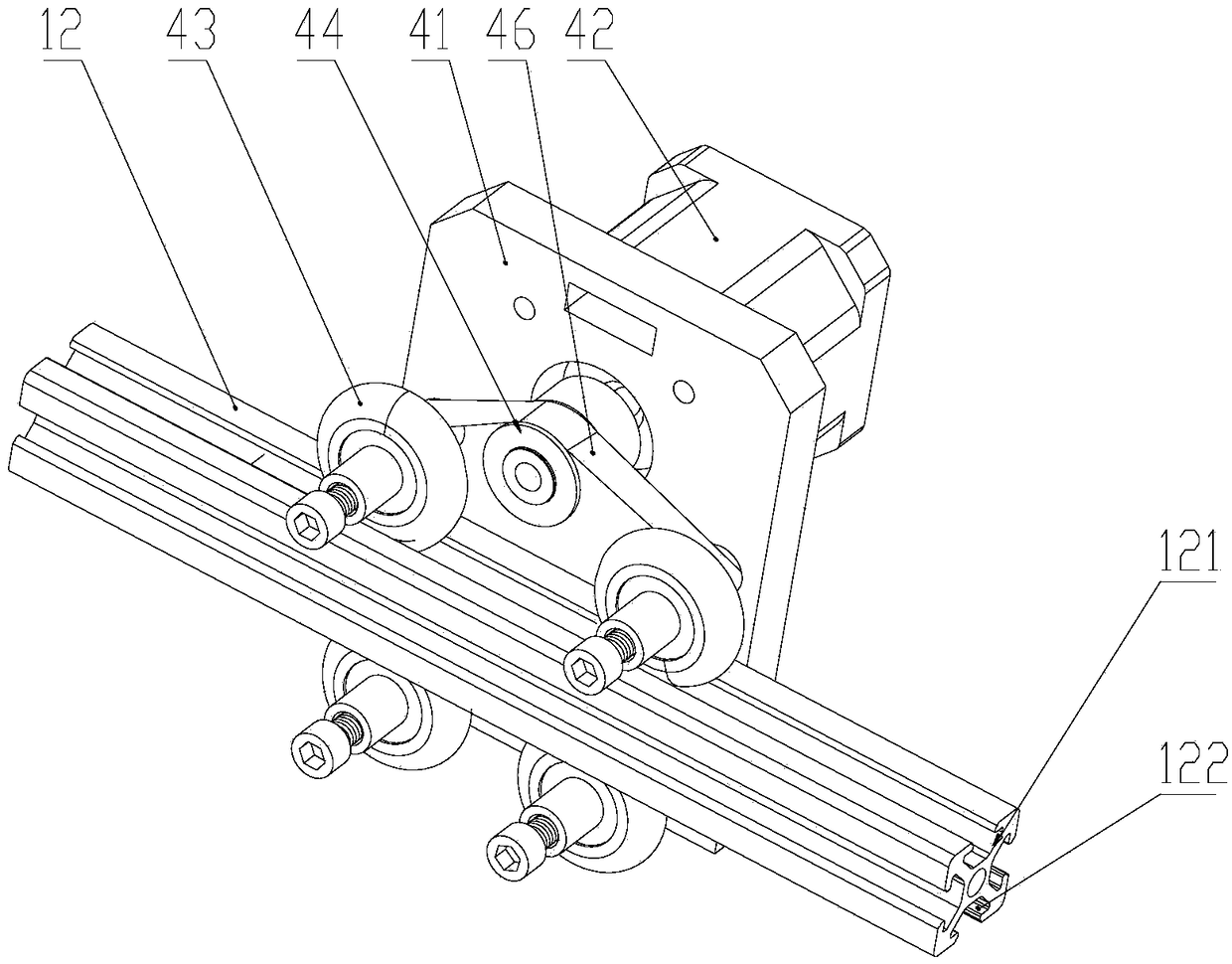

[0022] Automatic cloth dyeing machine, frame 1, cloth conveying mechanism 2, dye extruding device 3 and dye moving device 4; The frame 1 includes two longitudinal beams 11 parallel to each other and a crossbeam 12 between the two longitudinal beams 11, The two ends of the crossbeam 12 are respectively installed on the corresponding longitudinal beams 11; the cloth conveying mechanism 2 includes a cloth output mechanism positioned at one end of the longitudinal beam 11 and a cloth input mechanism positioned at the other end of the longitudinal beam 11; The input mechanisms all include an upper roller 21, a lower roller 22 and a cloth conveying motor 23; the two ends of the upper roller 21 and the lower roller 22 are respectively connected to the corresponding longitudinal beams 11 in rotation; the cloth conveying motor 23 is installed on one of them The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com