Coke particle preparation device

A preparation device and technology of carbon coke, which is applied in the field of carbon coke particle preparation devices, can solve the problems of carbon powder waste that is prone to dust and other problems, and achieve the effects of small thickness, easy compaction, and avoiding dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

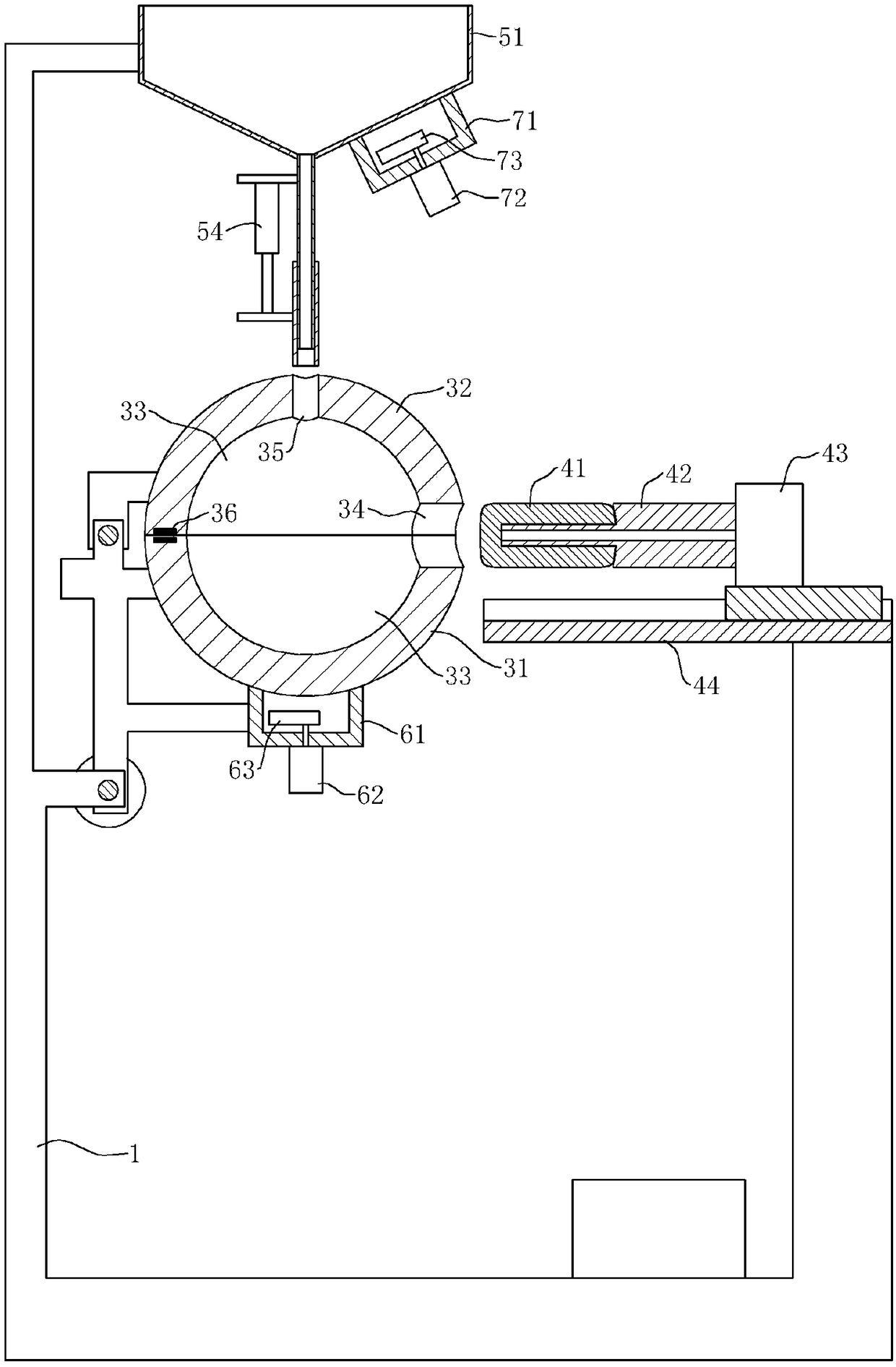

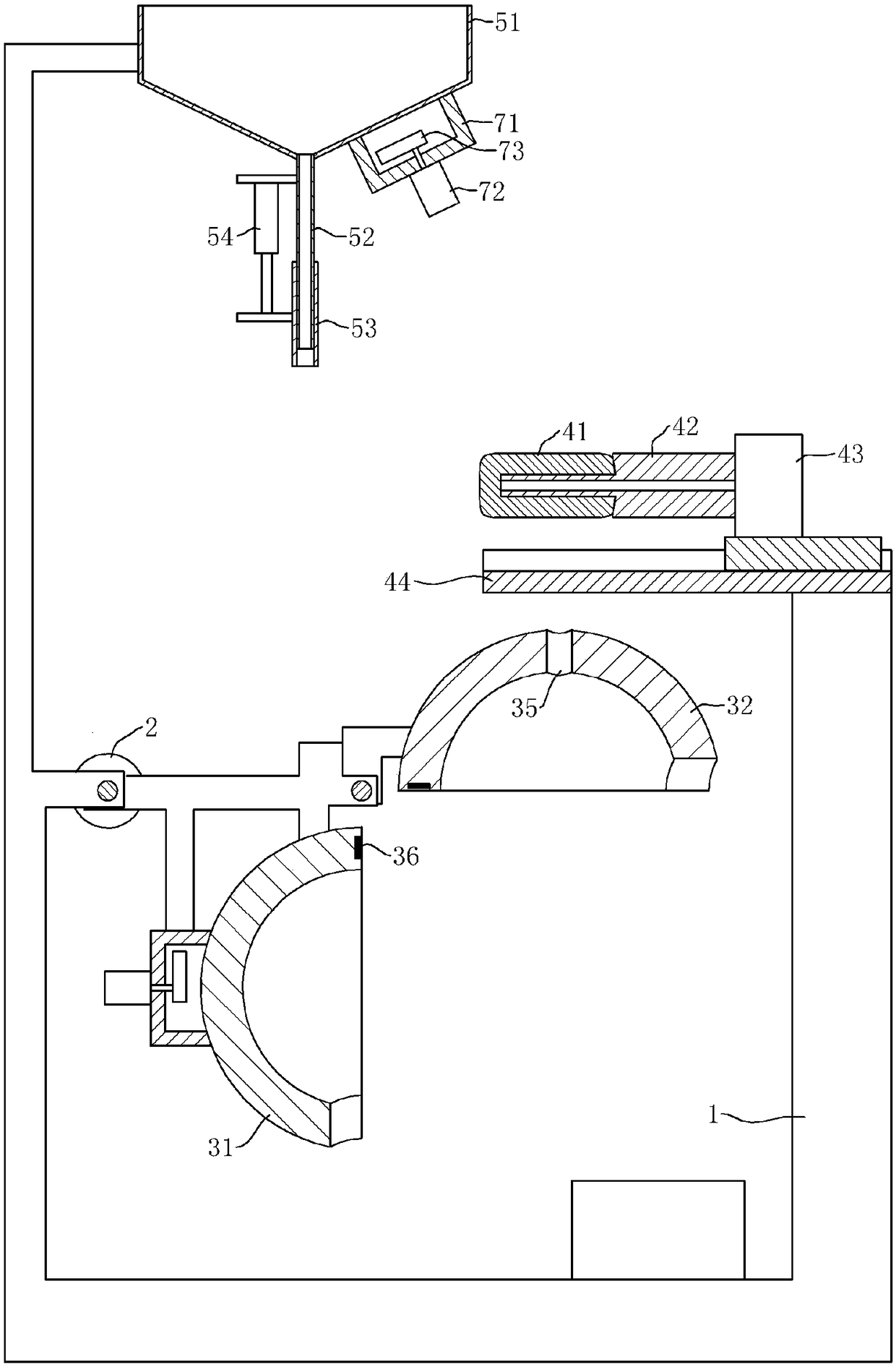

[0038] A charcoal particle preparation device, such as figure 1 Shown, comprise mould, extruding device, feeding device, frame 1 and stepping motor 2, mold comprises fixed mold 31 and movable mold 32; After the 31 are fastened together, a spherical cavity 33 is formed between the sides of the movable mold 32 and the fixed mold 31; and the linear module 44 are fixedly connected with the frame 1 respectively, one end of the conduit 42 is fixedly connected with the air bag 41, and the other end of the conduit 42 is fixedly connected with the air pump 43, and the air bag 41 communicates with the air pump 43 through the conduit 42; the linear module 44 and the conduit 42 is set horizontally, and the mold is provided with a first through hole 34 for the insertion of the conduit 42; the stepper motor 2 is fixedly connected with the frame 1, and the fixed mold 31 is fixedly connected with the output shaft of the stepper motor 2; the feeding device includes a hopper 51 and Telescopic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com