Colored copolymerized epoxy modified waterborne polyurethane and preparation method thereof

A water-based polyurethane and epoxy modification technology, applied in the field of polymer materials, can solve problems such as environmental pollution, and achieve the effects of avoiding large-scale use, low viscosity and moderate viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

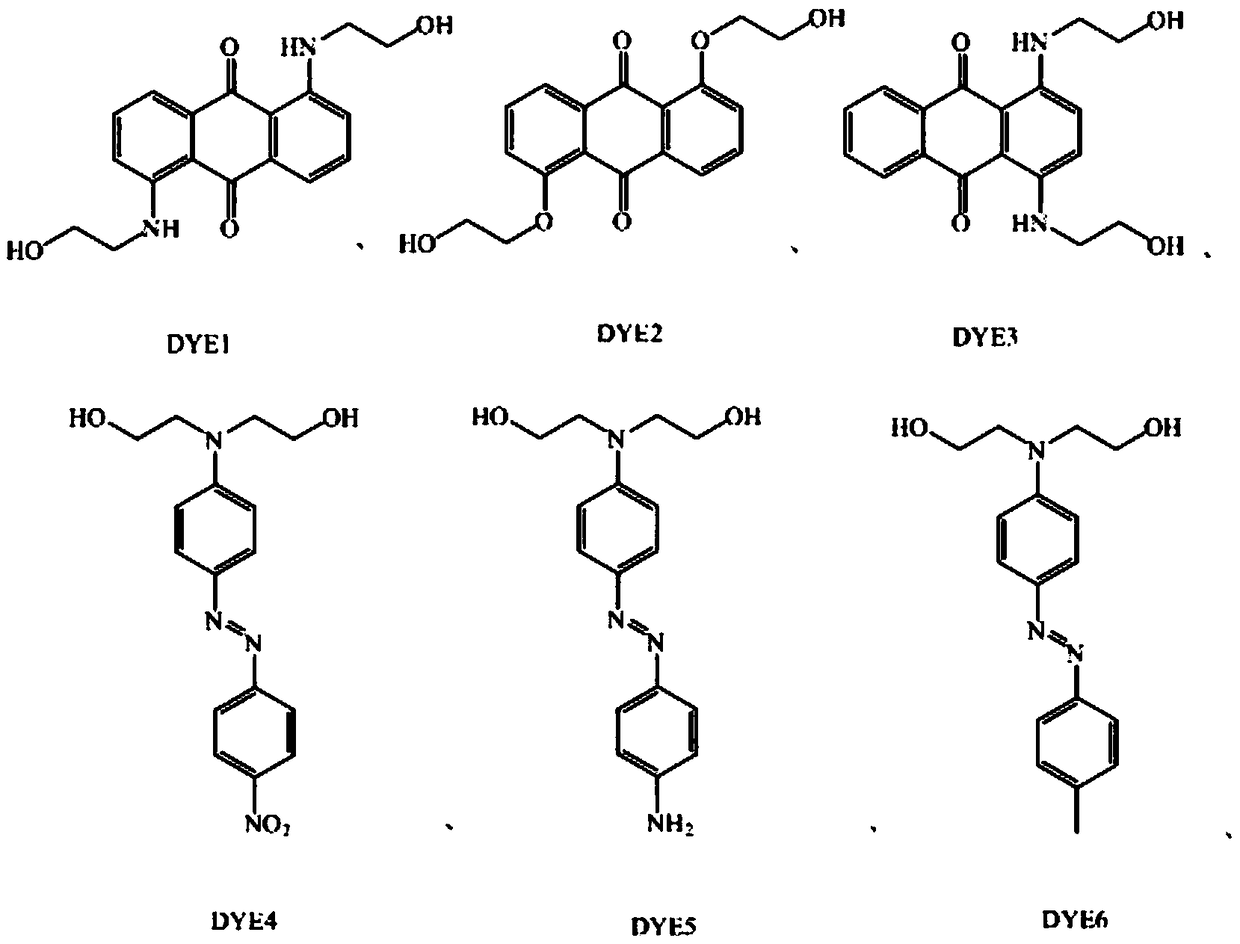

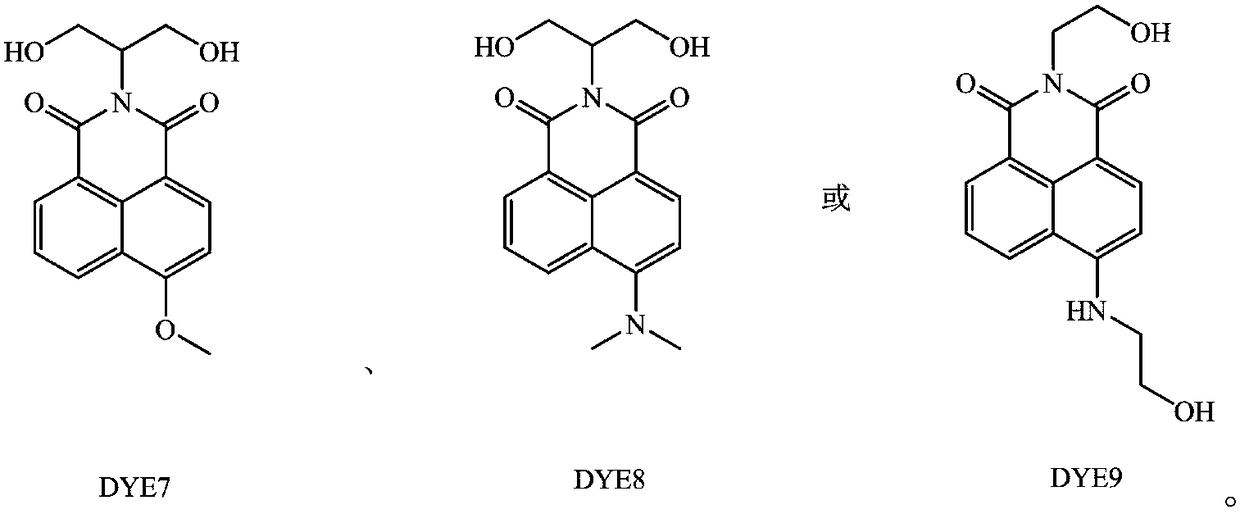

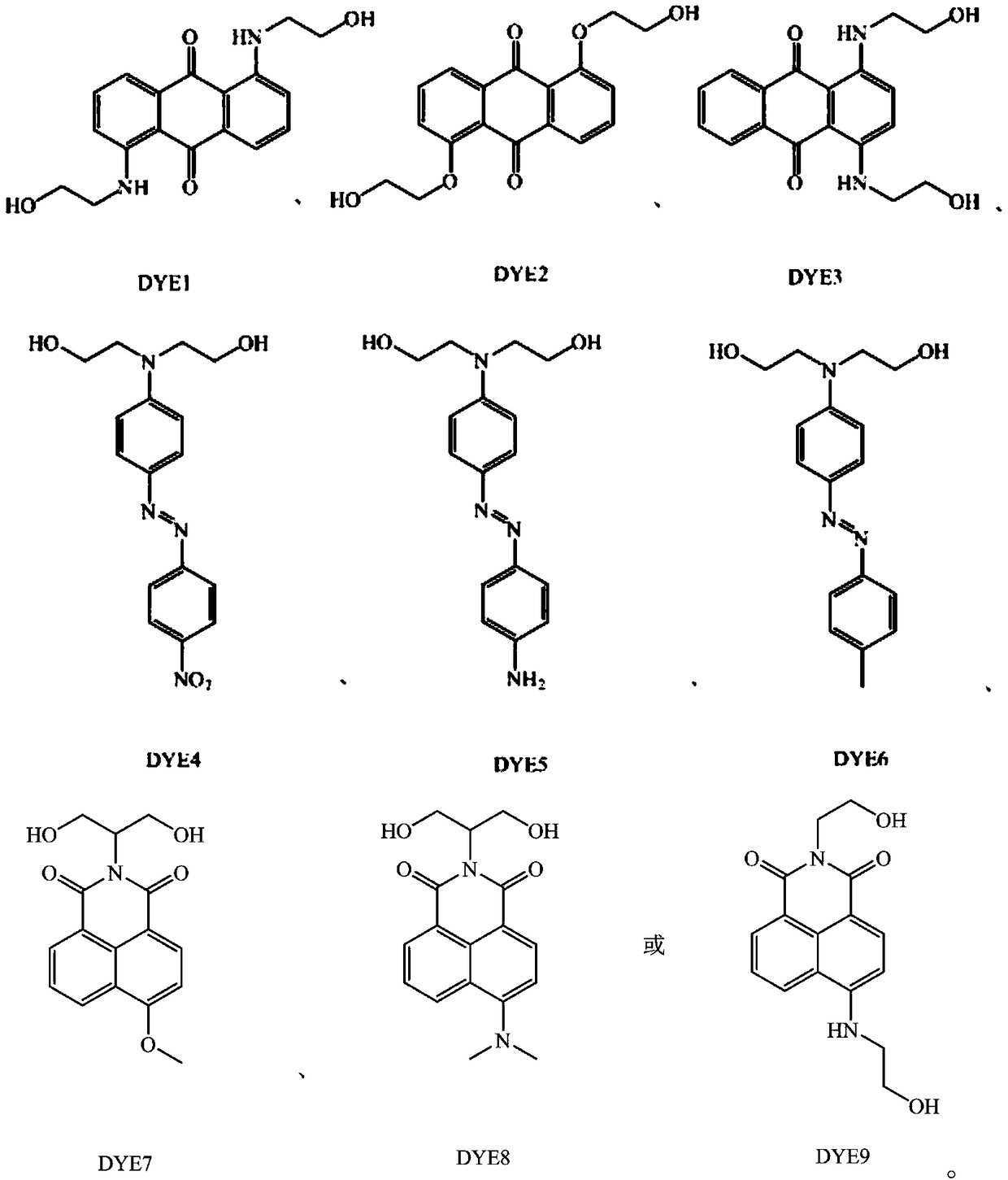

[0034] 10.0 g of PTMG (M n =1000) and 60.0 grams of BY3305 (M n =2000) dehydration at 100-120°C for 0.5-1.5 hours, then added 35.0 grams of IPDI, reacted at 90°C for 2 hours, added 10.0 grams of BDO, 0.89 grams of DYE1, reacted at 70°C for 2 hours, then added 0.094 grams of HQ and 0.851 g of HEMA was kept reacting at 60°C for 1.5 hours to obtain a polyurethane prepolymer with double bonds in the terminal group; then add 0.09 g of AIBN, 6.2 g of glycidyl methacrylate, add 100 mL of acetone, and add 285 mL of water under high-speed shearing , after stirring for 30 minutes, the reaction product was removed from the solvent acetone at 40°C and 0.01MPa vacuum conditions to obtain a block anionic water-based polyurethane emulsion Epoxy with a solid content of 30wt% and a glycidyl methacrylate content of 5.08wt%. -WPU1.

[0035] Among them, the structural formula of DYE1 is:

Embodiment 2

[0037] 5.0 grams of PCL (M n =1000) and 55.0 grams of BY3301 (M n=2000) was dehydrated at 100-120°C for 0.5-1.5 hours, then added 23.51 grams of TDI, reacted at 80°C for 2 hours, added 9.5 grams of DEG, 0.2 grams of TMP, 0.89 grams of DYE4, reacted at 70°C for 2 hours, then added 0.09 grams of BHT and 1.532 grams of HEMA were kept reacting at 60 ° C for 1 hour to obtain a polyurethane prepolymer with double bonds in the terminal group; 228mL of water was added under the pressure, and after stirring for 30 minutes, the reaction product was desolventized by acetone under 40°C and 0.01MPa vacuum conditions, and a block anionic compound with a solid content of 30wt% and a glycidyl methacrylate content of 3.07wt% was obtained. Water-based polyurethane emulsion Epoxy-WPU2.

[0038] Among them, the structural formula of DYE4 is

Embodiment 3

[0040] 50.0 grams of PPG (M n =2000), 6.0 g BY3306 (M n =550±30, effective content 70%±2) and 10.0 grams of BY3301 (M n =2000) was dehydrated at 100-120°C for 0.5-1.5 hours, then added 30.1 grams of IPDI, reacted at 80°C for 2 hours, added 5.1 grams of EG, 0.89 grams of DYE2, 0.15 grams of TIPA, reacted at 70°C for 2 hours, then added 0.06 g of BQ and 1.01 g of HPA were kept reacting at 60 ° C for 1 hour to obtain a polyurethane prepolymer with double bonds in the end group; then add 0.08 g of AIBN, 6.0 g of glycidyl methacrylate, add 130 mL of acetone, Add 254mL of water at low temperature, stir for 30 minutes, and remove the solvent acetone from the reaction product under 40°C and 0.01MPa vacuum conditions to obtain a block anionic compound with a solid content of 30wt% and a glycidyl methacrylate content of 5.51wt%. Water-based polyurethane emulsion Epoxy-WPU3.

[0041] Among them, the structural formula of DYE2 is

[0042] If other conditions of Example 3 remain unch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com