Advancing device and advancing method for polyurethane spraying foaming of prefabricated directly-buried thermal insulation tube

A prefabricated direct burial, polyurethane technology, applied in the direction of spraying device, etc., can solve the problem of uneven travel and rotation speed of steel pipes, and achieve the effect of ensuring density, ensuring production progress, and speeding up spraying speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

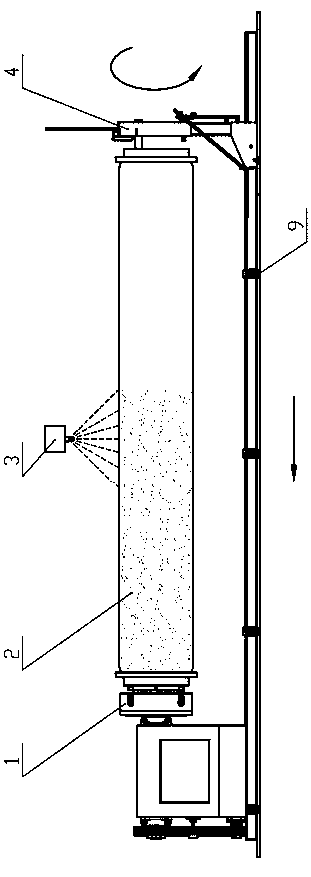

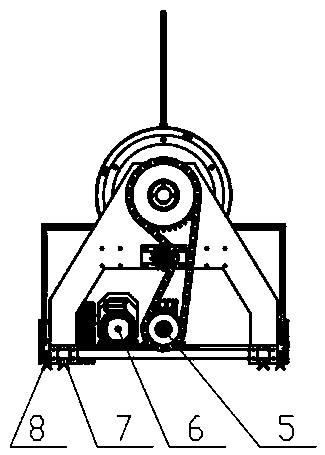

[0019] A traveling device for prefabricated direct-buried insulation pipe polyurethane spray foaming, which consists of: an inner chuck 1, a polyurethane spray gun 3, the inner chuck is a four-jaw linkage inner chuck, and There is one end of the steel pipe 2, the other end of the steel pipe is connected to the driven end 4, the two ends of the steel pipe are respectively covered with guard plates, the bottom of the driven end is equipped with a driven end guide rail 8, and the inner chuck The connecting shaft is connected to the steel pipe rotation power end 5, the bottom of the polyurethane spray gun is connected to the spraying travel power end 6, and the spraying travel power end includes a transmission mechanism, and the transmission mechanism makes the travel mechanism move horizontally through chain transmission , the traveling guide rail wheel 9 travels at a constant speed along the traveling guide rail 7, and the traveling guide rail is fixed on the ground.

Embodiment 2

[0021] According to the prefabricated direct-buried thermal insulation pipe polyurethane spray foaming traveling device described in Example 1, the steel pipe rotation power end includes its transmission mechanism, and the steel pipe is rotated by chain transmission, and the rotation speed is set at 100 mm / s-200mm / s s rotate at a constant speed, the distance between the polyurethane spray gun and the steel pipe is 800mm-900mm, and the horizontal travel speed of the steel pipe is 80mm / min-450mm / min.

Embodiment 3

[0023] A traveling device and a traveling method utilizing the polyurethane spray foaming of the prefabricated direct-buried thermal insulation pipe described in Embodiment 1-2, the method comprising the following steps:

[0024] (1) Put the guard plate on both ends of the steel pipe, then fix the steel pipe on the inner chuck, and connect the other end of the steel pipe to the driven end, and adjust it along the guide rail of the driven end , keep the steel pipe horizontal and fixed;

[0025] (2) Set the steel pipe rotation power end, set its rotation speed to 100mm / s-200mm / s, rotate at a constant speed, and at the same time adjust the distance between the polyurethane spray gun and the steel pipe to 800mm-900mm, Start spraying and foaming;

[0026] (3) After spraying and foaming start, the spraying traveling power end starts to travel horizontally at a preset speed, and the traveling guide rail wheels travel along the traveling guide rail at a constant speed, and the horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com