Tea rolling apparatus and tea processing method

A processing method and technology of a rolling device, which are applied in the field of tea rolling devices and tea processing, can solve problems such as uneven rolling, influence of tea taste, tea damage, etc., achieve sufficient tea rolling, convenient tea rolling, and improve processing quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

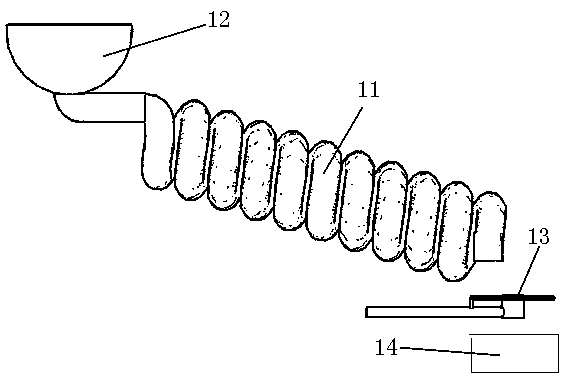

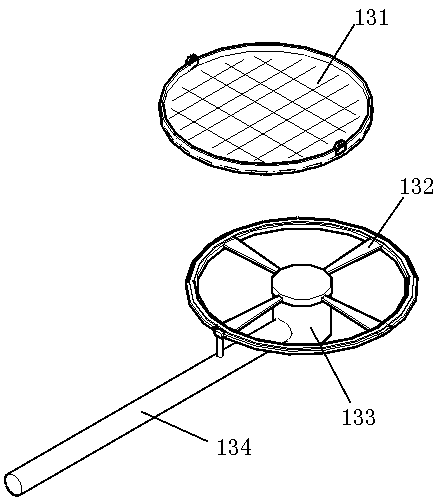

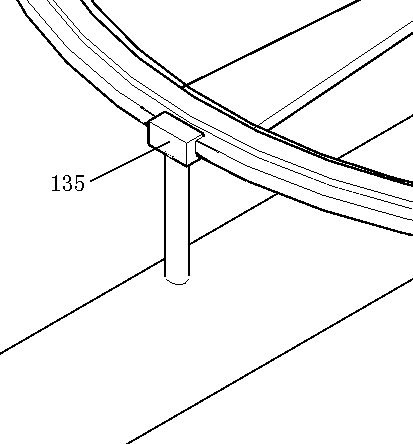

[0034] Such as Figure 7 Shown, a kind of tea rolling device comprises circulating feed belt assembly one 41, a pair of tea light pressing rollers 42, circulating feeding belt assembly two 43, a pair of tea heavy pressing rollers 44, circulating feeding belt assembly three 45, And some tea leaves gently kneading rollers 46, described feeding belt assembly one 41 comprises belt body reverse tension roller one 47, described tea light pressure roller 42 is docked with described belt body reverse tension roller one 47, and described feeding The second belt assembly 43 includes a second belt body reverse tension roller 48, the tea leaf weight roller 44 is docked with the second belt body reverse tension roller 48, and the third feeding belt assembly 45 includes a third feeding belt body, The tea lightly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com