A static contact structure and its fixed forming process with arc striking angle

A technology of molding process and arc striking angle, which is applied in the direction of breaker switch contacts, electrical components, electric switches, etc., can solve the problems of injury to the operator's body, loss of arc striking angle coating, and cost increase, so as to improve factory efficiency and avoid The matching process and the effect of reducing the cost of electroplating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

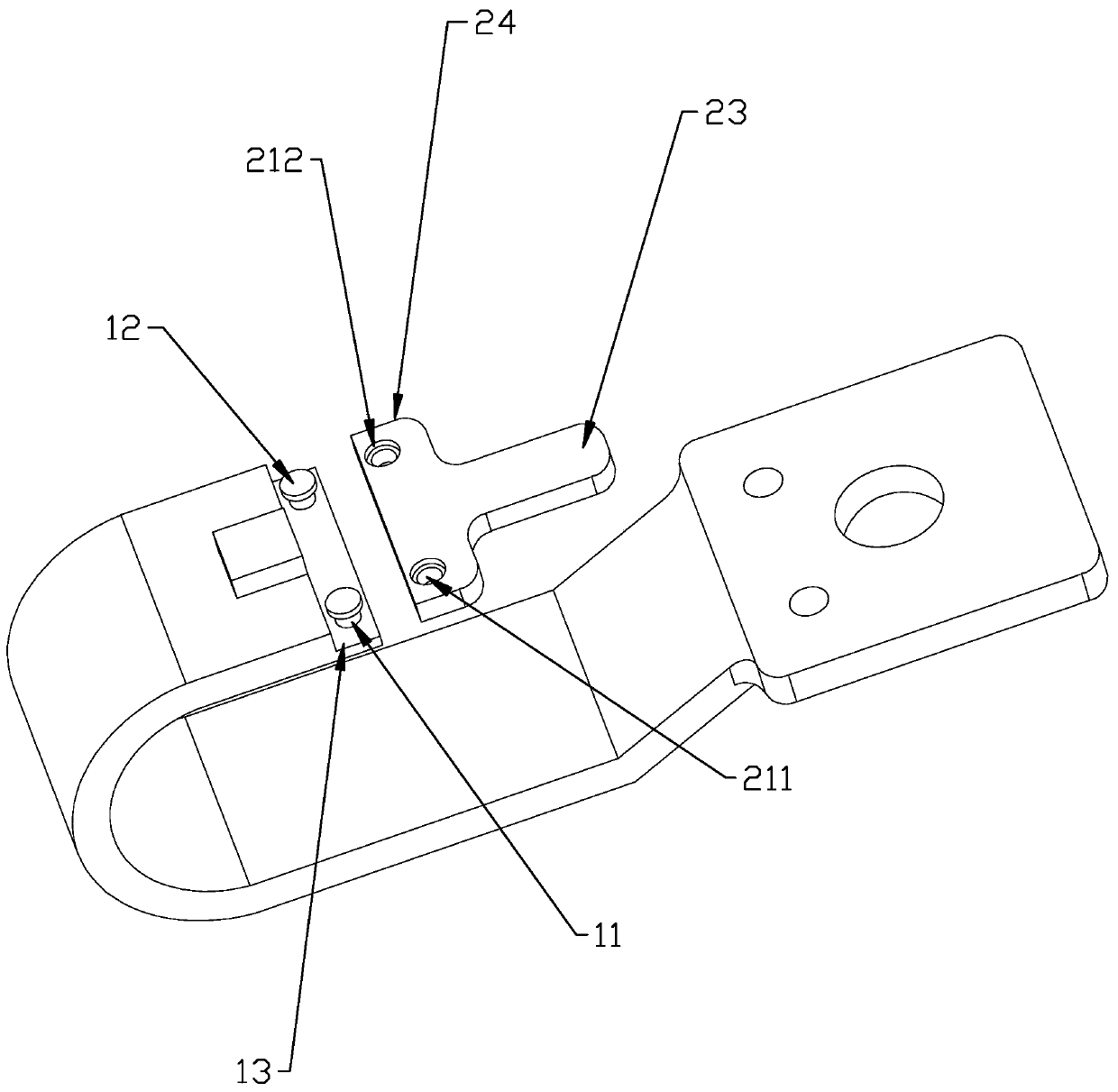

[0029] Such as Figure 1-2 As shown, a fixed forming process of the static contact and the arc striking angle 2 includes the following steps,

[0030] S1. Stamping and forming the connecting plate 1, and forming a stretching boss 11 at the connecting part of the connecting plate 1 and the arc striking angle 2;

[0031] S2, stamping the arc starting angle 2, and forming the installation through hole 21 adapted to the stretching boss 11 at the connection part between the arc starting angle 2 and the connecting plate 1, and the depth of the installation through hole 21 is smaller than that of the stretching boss height of table 11;

[0032] S3. Galvanizing the arc striking angle 2;

[0033] S4. Insert the stretching boss 11 into the installation through hole 21 and extend it to the outside of the installation through hole 21, then punch the exposed part of the stretching boss 11, and drive the stretching boss 11 to deform to form a limit flange 12, so that the arc striking angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com