Dryer for petroleum coke processing

A drying machine, petroleum coke technology, applied in the direction of drying machine, drying, non-progressive drying machine, etc., can solve the problem that the drying machine is not uniform and thorough, and achieve the effect of uniform and thorough drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

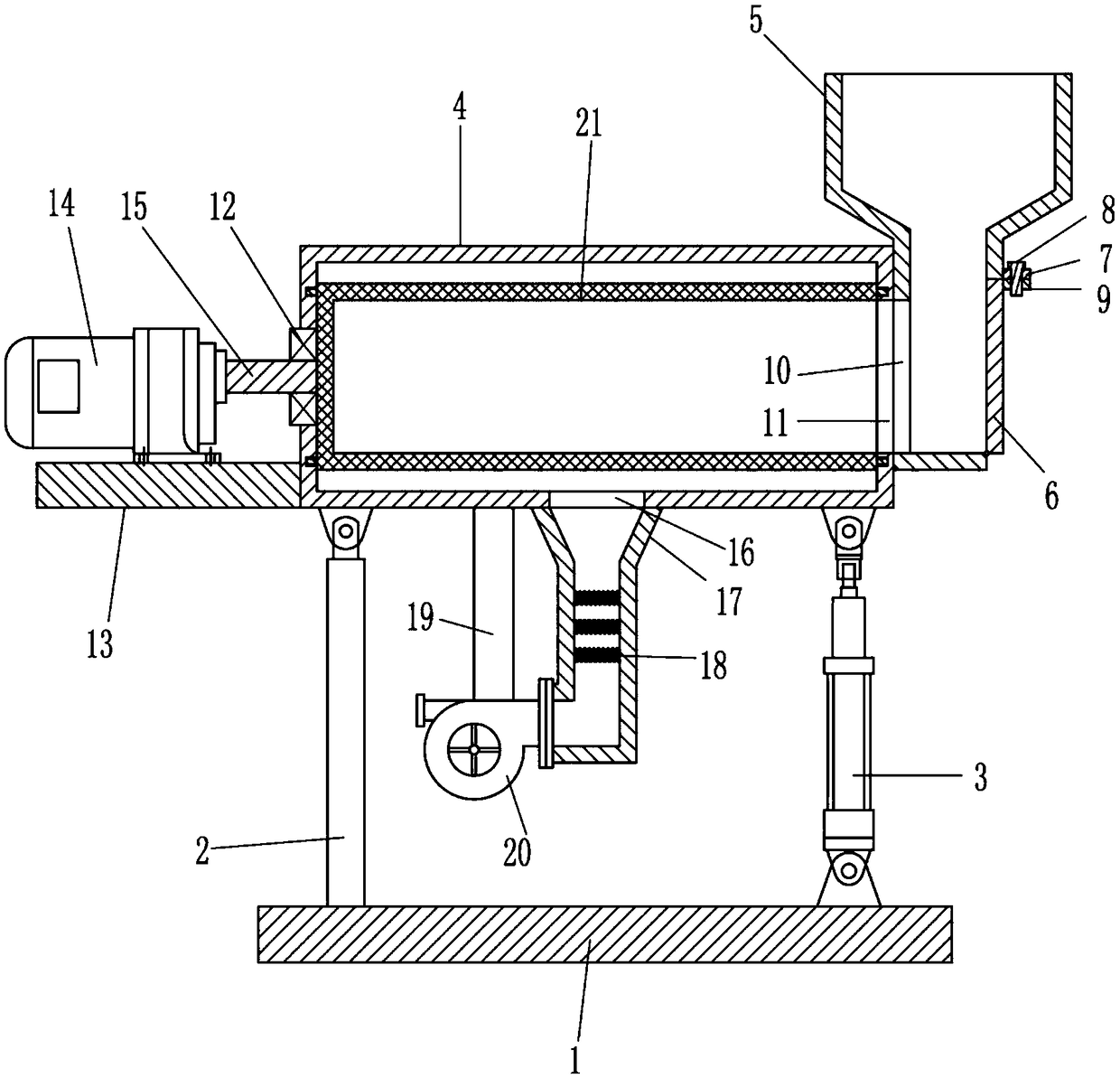

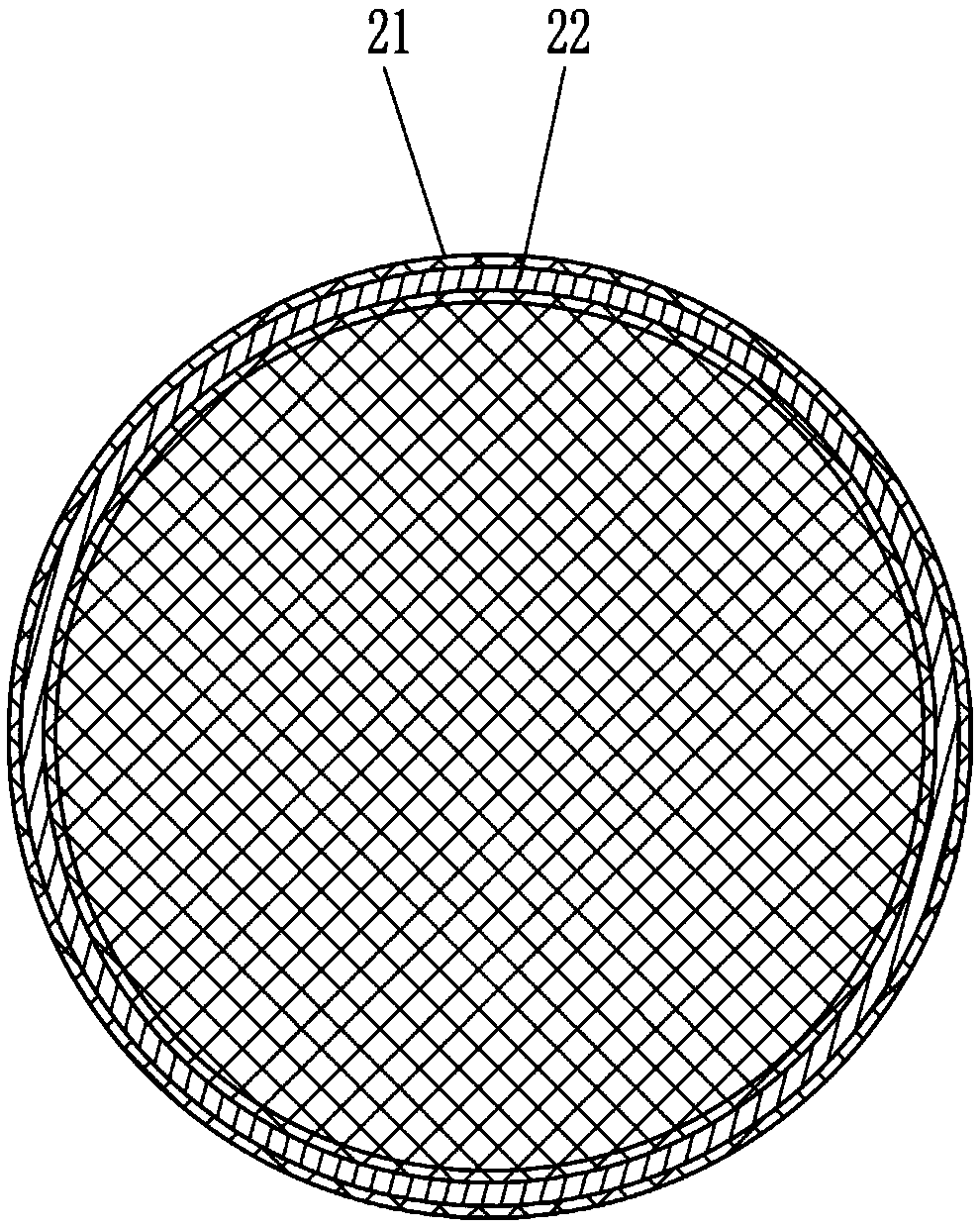

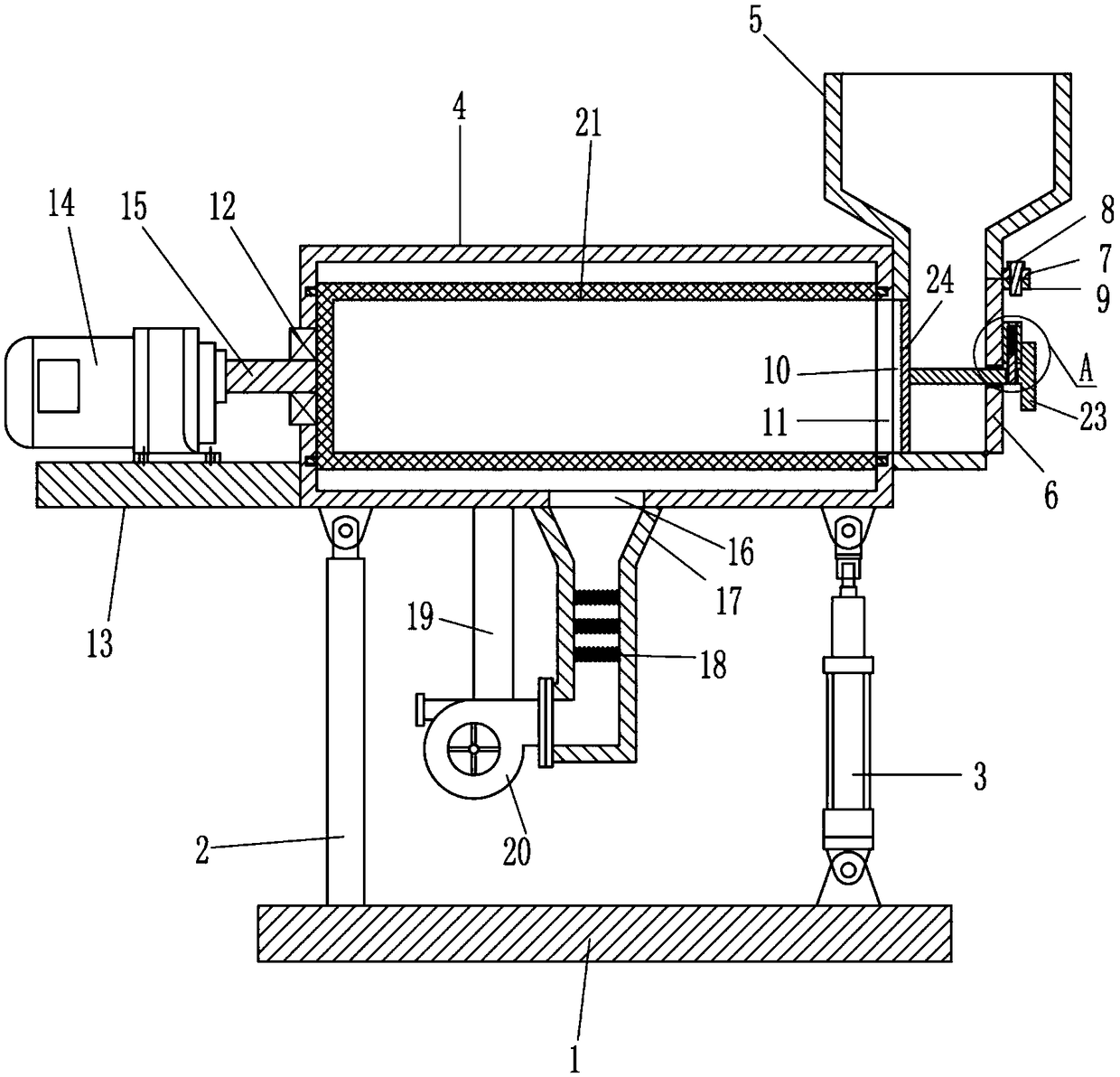

[0024] A dryer for petroleum coke processing, such as Figure 1-7 As shown, it includes bottom plate 1, support rod 2, cutting 3, drying cylinder 4, feeding hopper 5, cover plate 6, first fixing sleeve 7, fixing rod 8, second fixing sleeve 9, bearing seat 12, installation Plate 13, motor 14, rotating shaft 15, air intake pipe 17, heating wire 18, mounting frame 19, blower 20, hollowed out drum 21 and ring 22; support rod 2 is fixedly connected to the top end of base plate 1, and the cylinder is hinged to base plate 1 The other end of the top; the two ends of the drying cylinder 4 are respectively hinged with the support rod 2 and the cylinder, and there is a second inlet and outlet 11 near the end of the cylinder; the feeding hopper 5 is fixedly connected to the end of the drying cylinder 4 close to the cylinder, And there is a first inlet and outlet 10 communicating with the second inlet and outlet 11; the cover plate 6 is hinged on the side of the feed hopper 5 away from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com