Treatment device and treatment method of metal package surface hazardous wastes

A hazardous waste and treatment method technology, applied in the field of treatment devices for hazardous waste on the surface of metal packaging, can solve the problems of secondary pollution of the social environment and high operating costs, reduce emissions and operating costs, improve work efficiency, and realize reuse Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

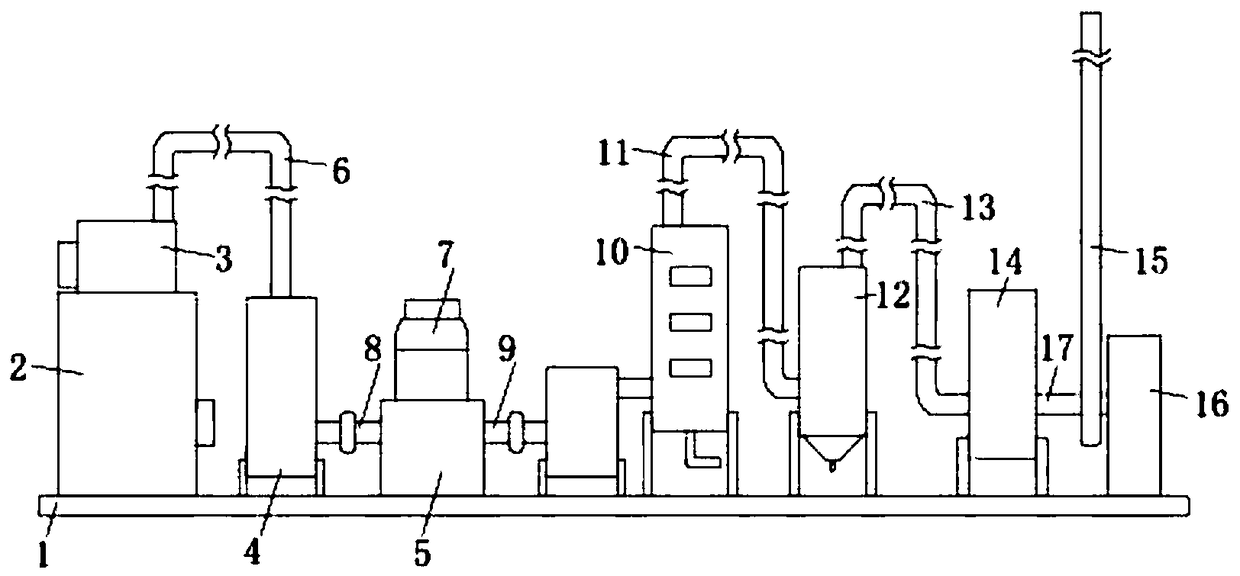

Embodiment 1

[0033] refer to figure 1 , a treatment device for hazardous waste on the surface of metal packaging, comprising a base 1, the upper end of the base 1 is sequentially provided with a thermal cleaning furnace, a heat exchanger 4, an SCR denitration reaction tower 5, an activated carbon injection system 10, and a wet deacidification tower 12 , the bag filter 14 and the induced draft fan 16, it should be noted that the thermal cleaning furnace can be replaced with any one of the pyrolysis furnace, cracking furnace and incinerator, and the upper end of the SCR denitration reaction tower 5 is provided with a heat exchange condenser 7. The thermal cleaning furnace includes a first combustion chamber 2 arranged on the base 1 and a second combustion chamber 3 arranged on the first combustion chamber 2, and the second combustion chamber 3 and the heat exchanger 4 pass through the first passage pipe 6 is connected, the heat exchanger 4 and the SCR denitration reaction tower 5 are connect...

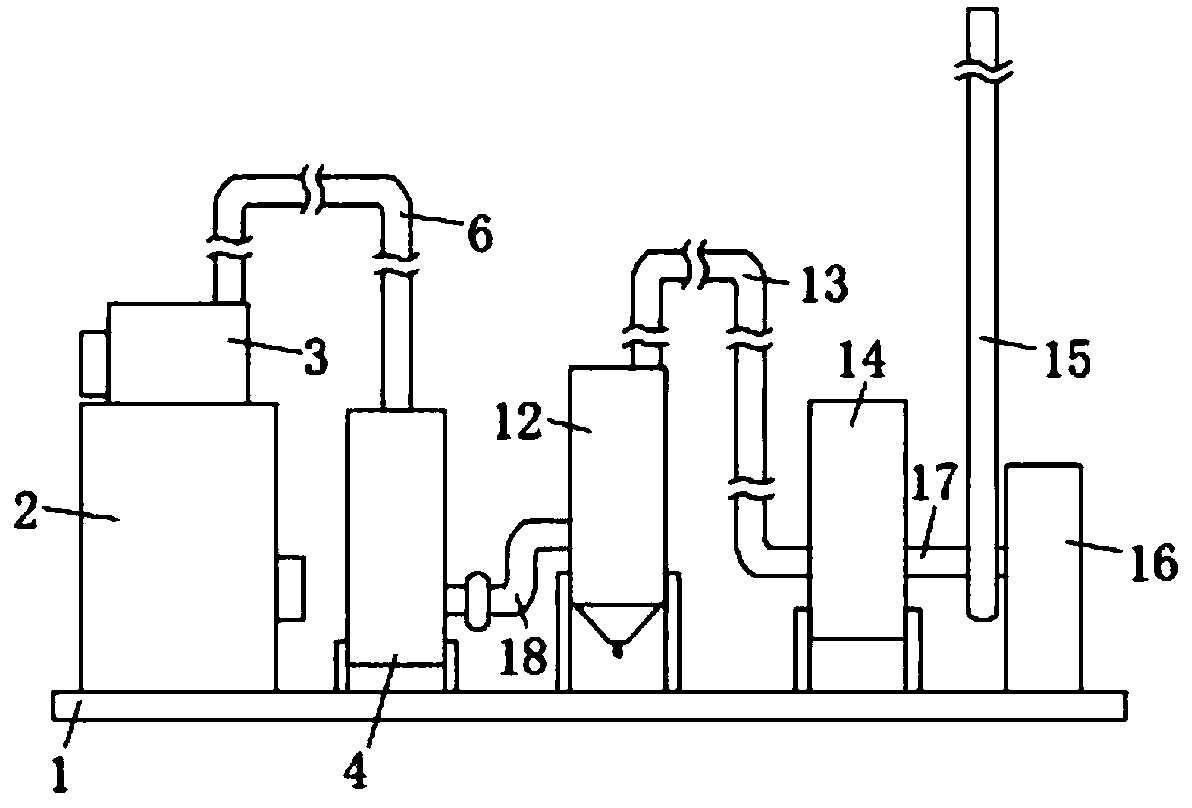

Embodiment 2

[0035] refer to figure 2 , a treatment device for hazardous waste on the surface of metal packaging, comprising a base 1, and the upper end of the base 1 is sequentially provided with a thermal cleaning furnace, a heat exchanger 4, a wet deacidification tower 12, a bag filter 14 and an induced draft fan 16. It should be noted that the thermal cleaning furnace can be replaced with any one of a pyrolysis furnace, a cracking furnace and an incinerator, and the thermal cleaning furnace includes a first combustion chamber 2 arranged on the base 1 and a first combustion chamber 2 arranged on the first combustion chamber 2 The second combustion chamber 3, the second combustion chamber 3 and the heat exchanger 4 are connected through the first channel pipe 6, and the heat exchanger 4 and the wet deacidification tower 12 are connected through the seventh channel pipe 18. The deacidification tower 12 and the bag filter 14 are connected by the fifth channel pipe 13, the bag filter 14 an...

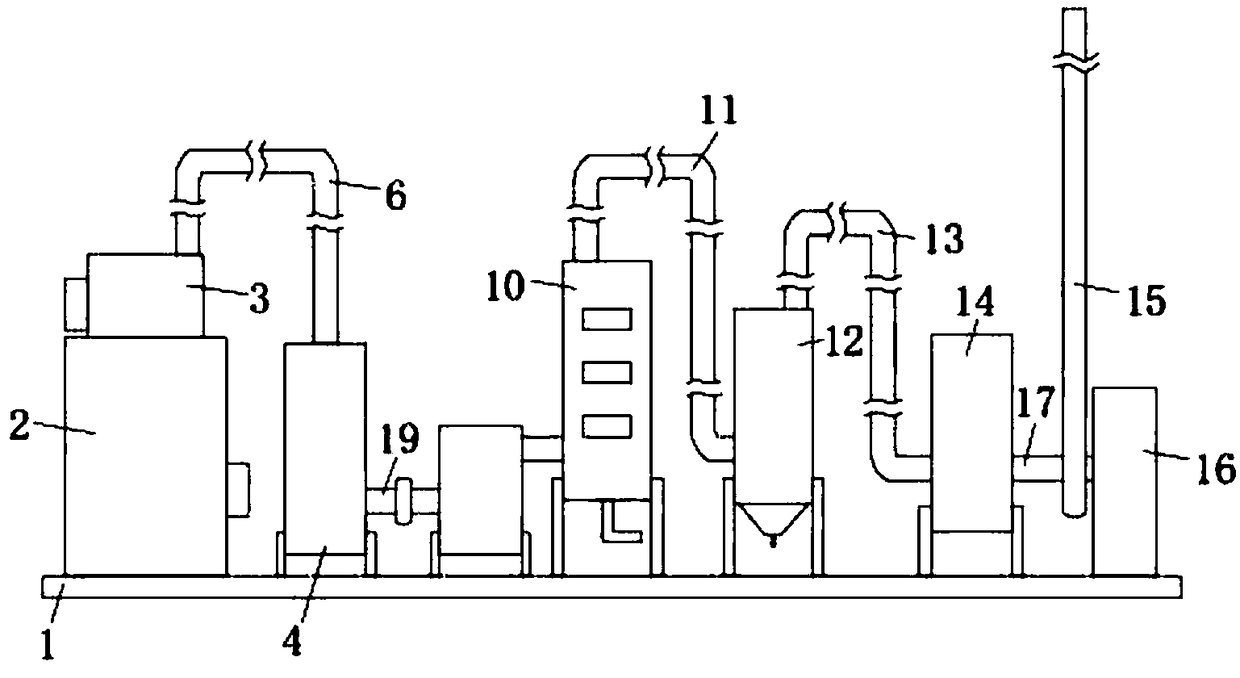

Embodiment 3

[0037] refer to image 3 , a treatment device for hazardous waste on the surface of metal packaging, comprising a base 1, the upper end of the base 1 is sequentially provided with a thermal cleaning furnace, a heat exchanger 4, an activated carbon injection system 10, a wet deacidification tower 12, a bag filter 14 and The induced draft fan 16, it should be noted that the thermal cleaning furnace can be replaced with any one of the pyrolysis furnace, cracking furnace and incinerator, and the thermal cleaning furnace includes a first combustion chamber 2 arranged on the base 1 and a A second combustion chamber 3 on a combustion chamber 2, the second combustion chamber 3 and the heat exchanger 4 are connected through the first channel pipe 6, and the heat exchanger 4 and the activated carbon injection system 10 are connected through the eighth channel pipe 19 , the activated carbon injection system 10 and the wet deacidification tower 12 are connected through the fourth channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com