Online static oil filter device and method for wind power generator gear case

A wind turbine, electrostatic oil filtering technology, applied in electrostatic separators, transmission parts, gear lubrication/cooling, etc., can solve the problem that sludge, oxides and too small metal debris cannot achieve effective filtering and oil purification problems such as limited capacity, to achieve the effect of long service life, large body surface area, and prolonging the life of the gearbox

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

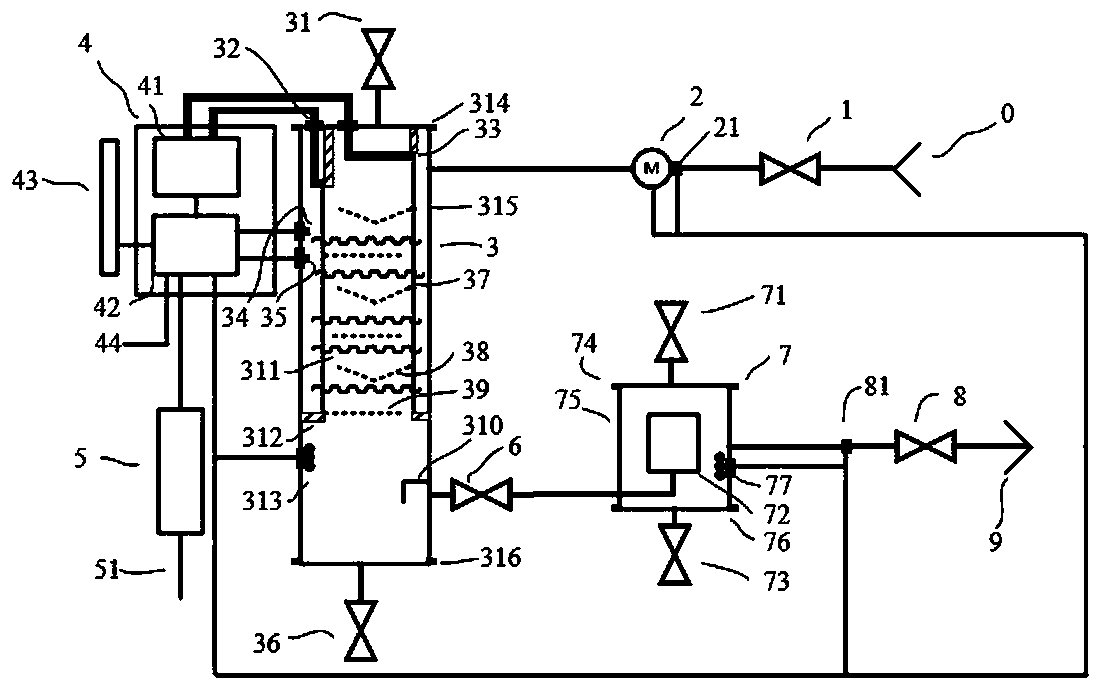

[0031] Such as figure 1 As shown, the on-line electrostatic oil filter device and method for the wind turbine gearbox described in the patent of the present invention includes the control box 4 and the distribution box 5 which are electrically connected in sequence; and also includes the oil inlet 0 and the inlet Valve 1, oil pump 2, electrostatic filter 3, intermediate valve 6, tail end filter 7, outlet valve 8 and oil outlet 9; inlet pressure sensor 21 is installed in the oil circuit between inlet valve 1 and oil pump 2; An outlet pressure sensor 81 is installed in the oil passage between the filter 7 and the outlet valve 8 .

[0032] The on-line electrostatic oil filter device and method for the wind power generator gearbox described in the patent of the present invention, in this embodiment, the electrostatic filter 3 is set as a box body, consisting of an upper end cover 314 of the electrostatic filter, a body 315 of the electrostatic filter, The electrostatic filter is ...

Embodiment 2

[0047] As shown in 2, the first installation method of the wind turbine gearbox online electrostatic oil filter device in the patent of the present invention, the wind turbine gearbox online electrostatic oil filter device A2 is connected in series with the wind turbine gearbox radiator A3 oil circuit. The gearbox lubricating oil containing impurities flows out from the wind turbine gearbox A1, first enters the wind turbine gearbox online electrostatic oil filter device A2 to filter, then enters the wind turbine gearbox radiator A3 to cool down, and then returns to the wind turbine gear box A1.

Embodiment 3

[0049] On the basis of Example 1, as image 3 The installation method 2 of the online electrostatic oil filter device of the wind turbine gearbox described in the patent of the present invention is shown. The oil circuit of the online electrostatic oil filter device A2 of the wind turbine gearbox and the radiator A3 of the wind turbine gearbox are independent of each other. The gearbox lubricating oil containing impurities flows out from the wind turbine gearbox A1, enters the wind turbine gearbox online electrostatic oil filter device A2 to filter, and then returns to the wind turbine gearbox A1. The hot gearbox lubricating oil flows out from the wind turbine gearbox A1, enters the wind turbine gearbox radiator A3 to cool down, and then returns to the wind turbine gearbox A1.

[0050] It takes a certain amount of time for the charged impurities to be captured by the dust collector, and the flow rate of the radiator cannot be too low under high power. When the first installat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com