Exerting device for I-beam prestressing

A technology of applying device and I-beam, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of the limitation of the applied prestress, the inability to use, and the high linearity requirements of prestressed steel bars, so as to improve the tensioning efficiency. , flexible use, good seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

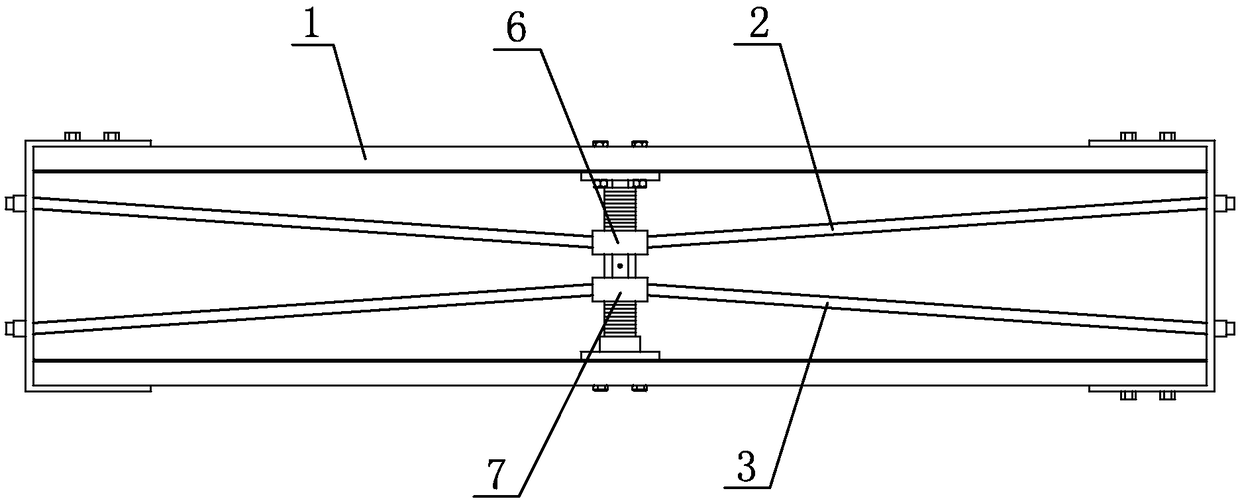

[0022] As shown in the figure, a device for applying I-beam prestress includes two-way tension mechanisms arranged in the flanges on both sides of I-beam 1. The two-way tension mechanism is located in the middle of I-beam 1, and each The upper steel strand 2 and the lower steel strand 3 are arranged in the side flange, and the two ends of the I-beam 1 are respectively fixed with the connecting plate 4, and the two ends of the upper steel strand 2 and the lower steel strand 3 are respectively corresponding to it. The connecting plate 4 at the end is fixedly connected, and the two-way tension mechanism includes an upper sleeve 51, a lower sleeve 52, a connecting sleeve 53, an upper pull block 6, a lower block 7 and a bracket 8, and the bracket 8 includes an upper base plate 81, a lower base plate 82 and a support shaft 83, the upper base plate 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com