Fabricated shear wall vertical joint connecting structure and accessories, application, calculation and construction of fabricated shear wall vertical joint connecting structure

A technology for connecting components and connecting structures, which is applied in computing, building components, special data processing applications, etc., and can solve problems such as inability to construct joints, inability to match or better seismic performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

[0062] The shear wall described in the present invention is the noun of "Technical Regulations for Concrete Structures of High-Rise Buildings JGJ3-2010", and the wall described in "Specifications for Design of Concrete Structures GB50010-2010", which has already been described in "Code for Seismic Design of Buildings GB50011-2010". The above-mentioned anti-seismic wall is a vertical member of the same building structure.

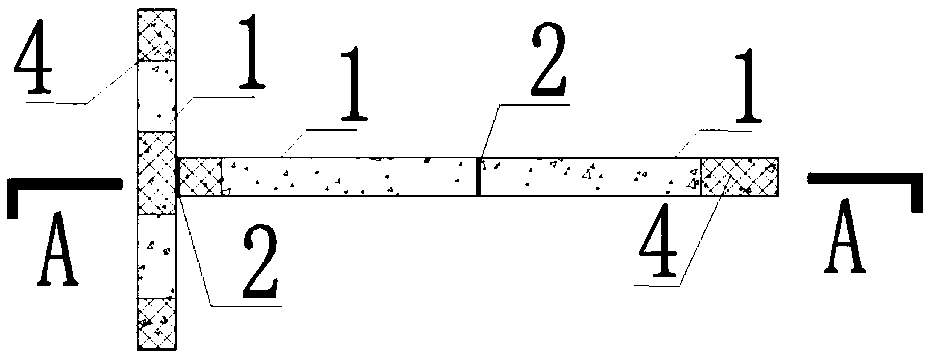

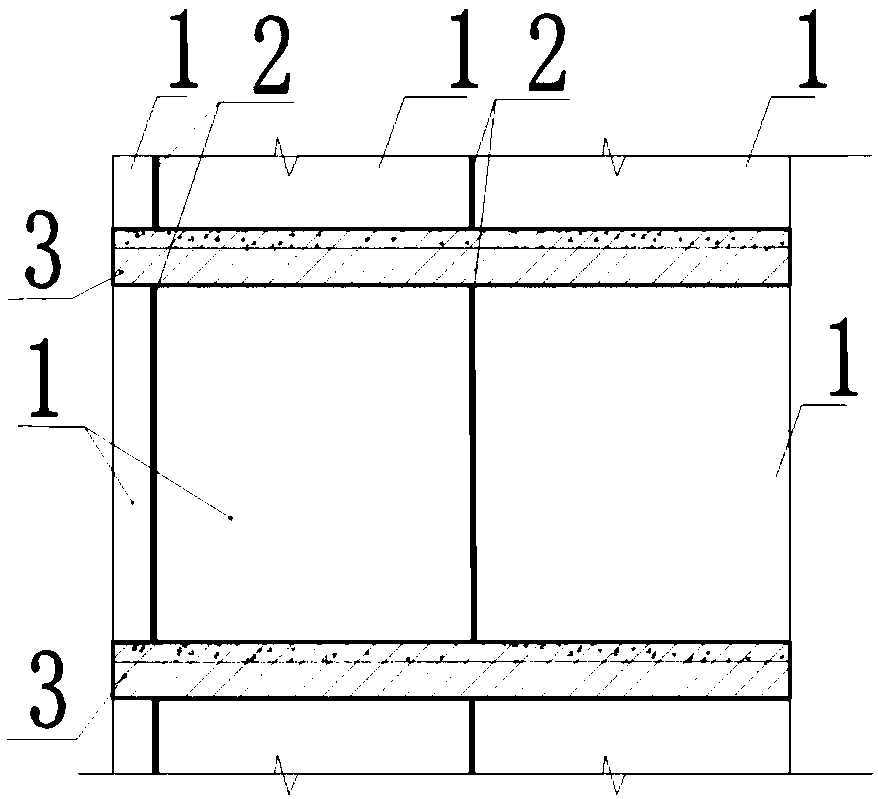

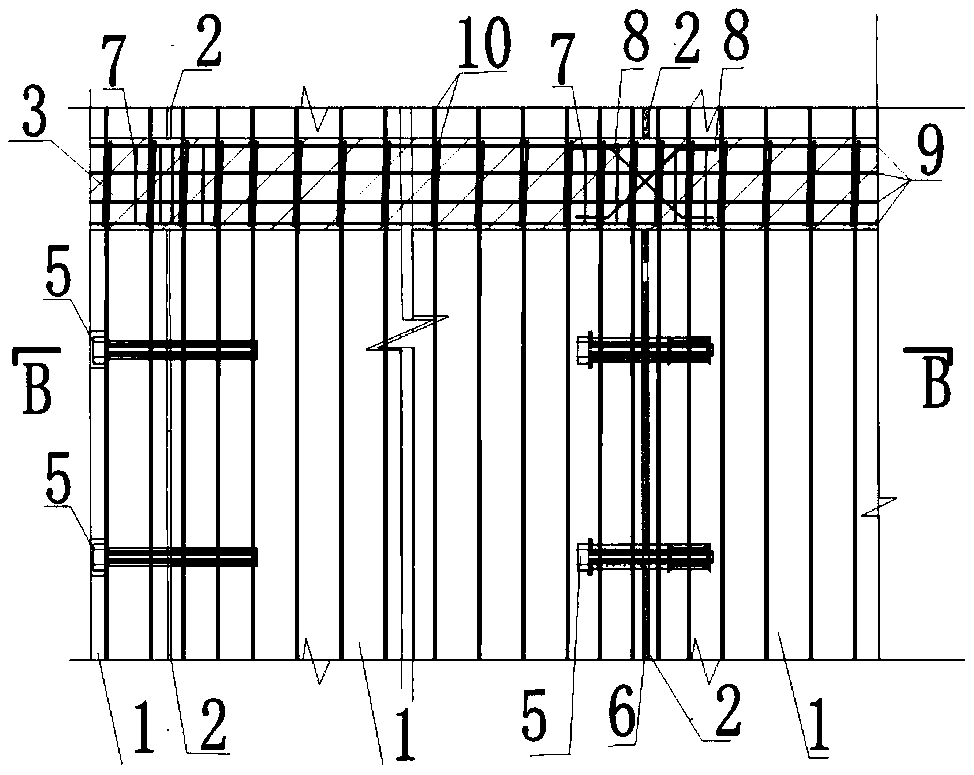

[0063] Figure 3-Figure 8 Shown is the connection structure of the vertical joint 2 of the assembled shear wall, wherein the assembled shear wall is a prefabricated concrete structure shear wall, and the prefabricated shear wall unit 1 connects the first prefabricated shear wall through the connecting member 5 The wall unit 1 and the second prefabrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com