Unidirectional large damping friction pendulum supporting seat

A technology of friction pendulum support and one-way damping, which is applied to bridge parts, bridge construction, building components, etc., can solve the problems of large residual displacement and low frictional energy consumption, and achieve high bearing capacity and small friction coefficient in the return direction , design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

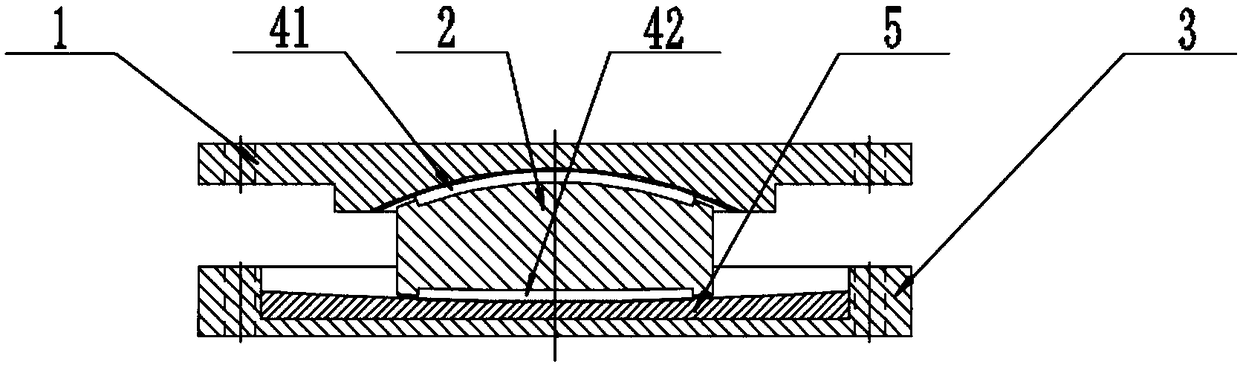

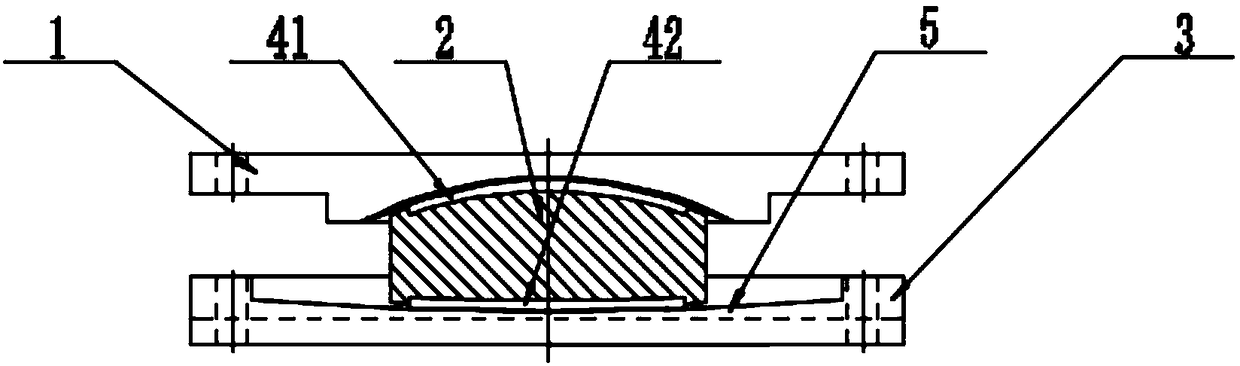

[0031] like Figure 1 to Figure 4 As shown, a one-way large damping friction pendulum support includes an upper seat plate 1, a double convex curved surface ball core 2, and a lower seat plate 3 arranged sequentially from top to bottom; the lower seat plate 3 is a basin structure, and its upper part is set There is a groove, and a one-way damping plate 5 is arranged in the groove; an upper ultra-high pressure wear-resistant plate 41 is arranged between the upper seat plate 1 and the double-convex curved surface core 2, and the double-convex curved surface ball core 2 and the one-way damping plate 5 A lower ultra-high pressure wear-resistant plate 42 is arranged between them.

[0032] In the present invention, the upper and lower end surfaces of the biconvex curved surface core 2 are convex spherical surfaces; more flat.

[0033] Further, the upper end surface of the one-way damping plate 5 is a concave spherical surface adapted to the lower end surface of the biconvex spheri...

Embodiment 2

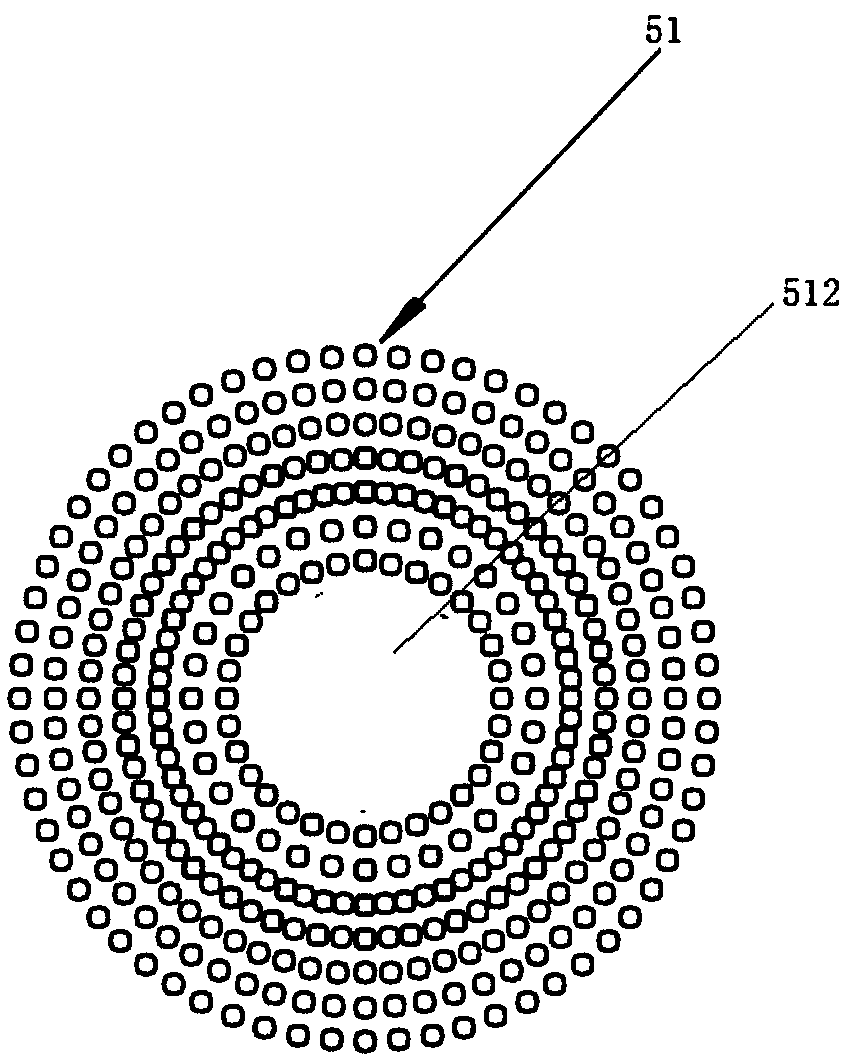

[0039] Different from Embodiment 1, in this embodiment, the dotted texture structure 51 is discontinuous and finely distributed in concentric circles, wherein each ring is discontinuous and discontinuous, that is, each ring is divided into Several small circular arcs set intermittently.

[0040] During the earthquake, due to the friction between the lower ultra-high pressure wear-resistant plate 42 and the one-way damping plate 5, the lower end surface of the lower ultra-high pressure wear-resistant plate 42 will wear and produce fine wear particles; these fine wear Particles can be cleaned out through the gaps between the small arcs, so as to ensure the smooth operation of the bearing.

[0041] In the present invention, the ultra-high pressure wear-resistant plate refers to a wear-resistant material with a compressive stress above 60Mpa; wherein, the upper ultra-high pressure wear-resistant plate 41 can use the MSM wear-resistant plate of German Maurer; the lower ultra-high pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com