Fabricated concrete structure joint connection prefabricated part and connection mode thereof

A concrete structure and node connection technology, applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problem of inability to detect whether the steel sleeve grouting material is filled, the connection strength of two connecting steel bars cannot be guaranteed, and the grouting quality of grouting can be solved. The quality decline and other problems, to achieve the effect of adjustable longitudinal connection length, convenient hoisting, and simplifying the difficulty of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

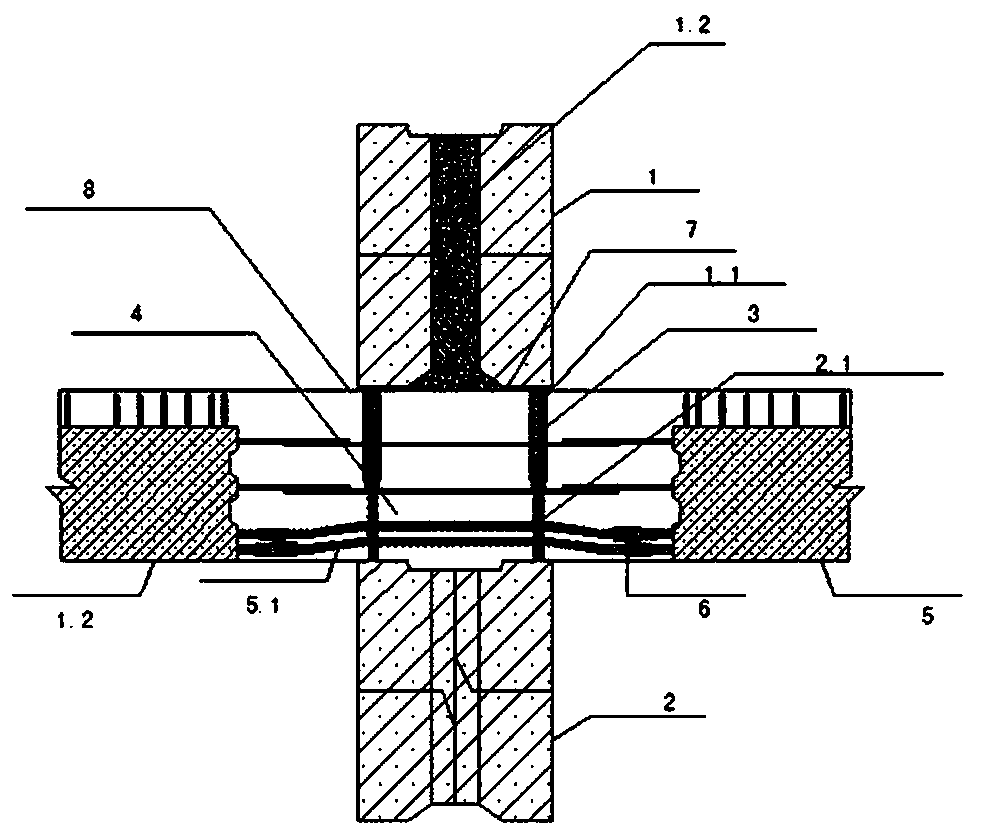

[0023] Example 1: as figure 1 , 2 As shown, a prefabricated concrete is connected to prefabricated parts with vertical longitudinal reinforcement, including prefabricated upper truncated column 1, prefabricated lower truncated column 2, and prefabricated composite beam 5. The prefabricated composite beam 5 is divided into two sections, and the two sections are prefabricated The joint area 4 is formed between the composite beam 5 and the prefabricated upper sectional column 1 and the prefabricated lower sectional column 2, and the two sections of the prefabricated composite beam 5 are provided with horizontal reserved longitudinal reinforcement 5.1 running through its length direction and protruding from its two ends , the horizontal reserved longitudinal reinforcement 5.1 between the two sections of prefabricated composite beams is connected through the steel connection sleeve 6, and the connection sleeve 6 can be selected according to the actual situation during the connectio...

Embodiment 2

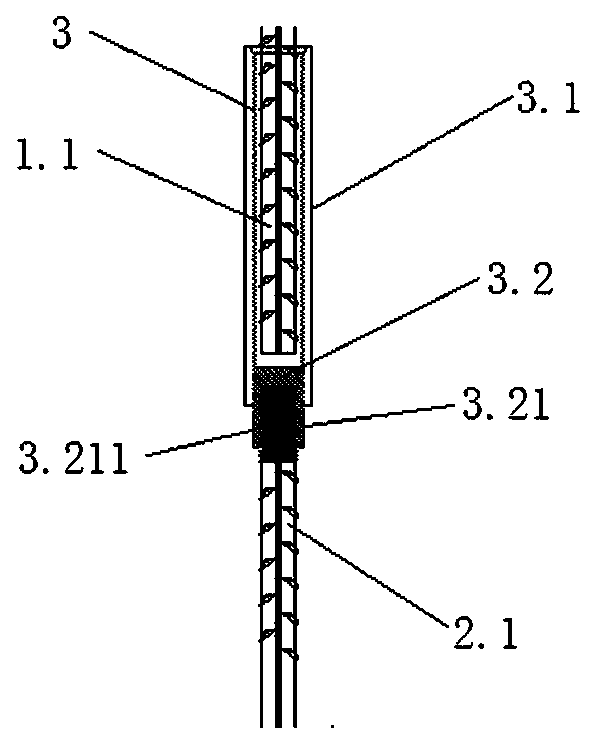

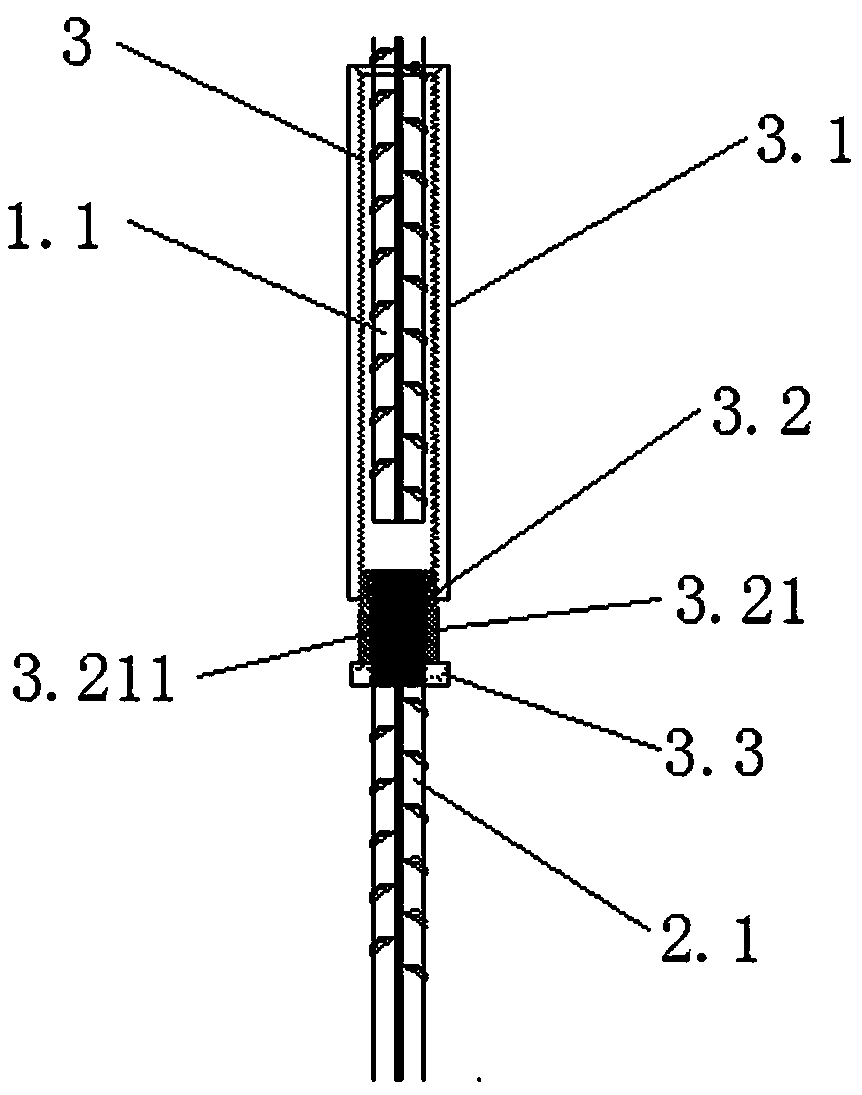

[0024] Embodiment 2: When carrying out construction work, after splicing the prefabricated lower section column 2 and the two sections of prefabricated composite beams 5, a spliced node area 4 is formed, and the spliced node 4 area is filled with concrete pouring; The semi-grouting steel bar joint 3 used for steel bar connection is screwed on several reserved longitudinal reinforcements 2.1 protruding from the upper end surface of the prefabricated lower column 2; the prefabricated upper column 1 is hoisted directly above the prefabricated lower column 2, and then Grouting is carried out in the connecting sleeve 3.1 of the semi-grouting steel bar joint 3 for vertical steel bar connection. After the grouting is full, several upper reserved longitudinal bars 1.1 protruding from the lower end surface of the prefabricated upper section column 1 are inserted into the connecting sleeve 3.1, and the upper prefabricated When the longitudinal reinforcement 1.1 is inserted into the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com