Non-quenched and tempered steel for motor shaft of new energy electric vehicle and production method of non-quenched and tempered steel

A non-quenched and tempered steel and production method technology, applied in the direction of manufacturing converters, etc., can solve the problems of long production cycle and high production cost, and achieve the effects of improving machinability, increasing yield ratio, and increasing Si element content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

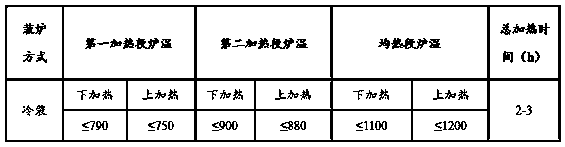

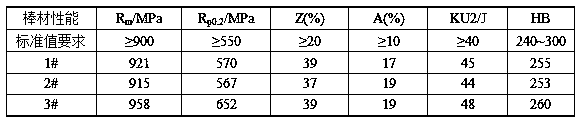

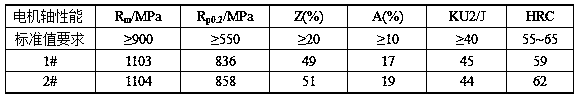

[0033] For the refining of high-purity steel, the range of Mn is controlled at 0.99~1.02% during LF smelting; after RH is broken, the hydrogen is determined: [H]≤2.0ppm, and then the temperature is taken by sampling, and the N-Mn line is carried out according to the analysis results of the oxygen nitrogen meter. Supplementary feeding of Al wire is not allowed during the smelting process; after the LF smelting is completed, the content of the added silicon-calcium wire is determined according to the Al content in the spectral composition; during the RH vacuum process, the Al wire 2 o 3 Fully carry out denaturation treatment; immediately feed titanium wire, manganese nitride cored wire, and sulfur wire to adjust the content of Ti, N, and S after breaking the air; softly blow argon for 20 minutes and hang the bag after the composition is uniform; before rolling, the first The lower heating temperature of the furnace temperature in the heating section is 750°C, and the upper heati...

Embodiment 2

[0036] The production process is basically the same as in Example 1: for the refining of high-purity steel, the range of Mn is controlled at 0.99~1.02% during LF smelting; hydrogen is determined after RH is broken: [H]≤2.0ppm, and then the temperature is measured by sampling. The supplementary feeding of N-Mn wire is carried out according to the analysis results of the oxygen and nitrogen meter, and the Al wire is not allowed to be fed during the smelting process; after the LF smelting is completed, the content of the added silicon-calcium wire is determined according to the Al content in the spectral composition; al 2 o 3 Fully carry out denaturation treatment; immediately feed titanium wire, manganese nitride cored wire, and sulfur wire to adjust the content of Ti, N, and S after breaking the air; softly blow argon for 25 minutes and hang the bag after the composition is uniform; before rolling, the first The lower heating temperature of the furnace temperature in the heati...

Embodiment 3

[0039] The production process is basically the same as in Example 1: for the refining of high-purity steel, the range of Mn is controlled at 0.99~1.02% during LF smelting; hydrogen is determined after RH is broken: [H]≤2.0ppm, and then the temperature is measured by sampling. The supplementary feeding of N-Mn wire is carried out according to the analysis results of the oxygen and nitrogen meter, and the Al wire is not allowed to be fed during the smelting process; after the LF smelting is completed, the content of the added silicon-calcium wire is determined according to the Al content in the spectral composition; al 2 o 3 Fully carry out denaturation treatment; immediately feed titanium wire, manganese nitride cored wire, and sulfur wire to adjust the content of Ti, N, and S after breaking the air; softly blow argon for 20 minutes and hang the bag after the composition is uniform; before rolling, the first The lower heating temperature of the furnace temperature in the heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com