Edible packaging film, and preparation method and application thereof

A packaging film and starch-based technology, applied in the field of packaging materials, can solve the problems of restricting large-scale production, mechanophysical methods are rarely reported, and high energy-consuming processes, so as to achieve low cost, solve energy and environmental problems, and improve the production process Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

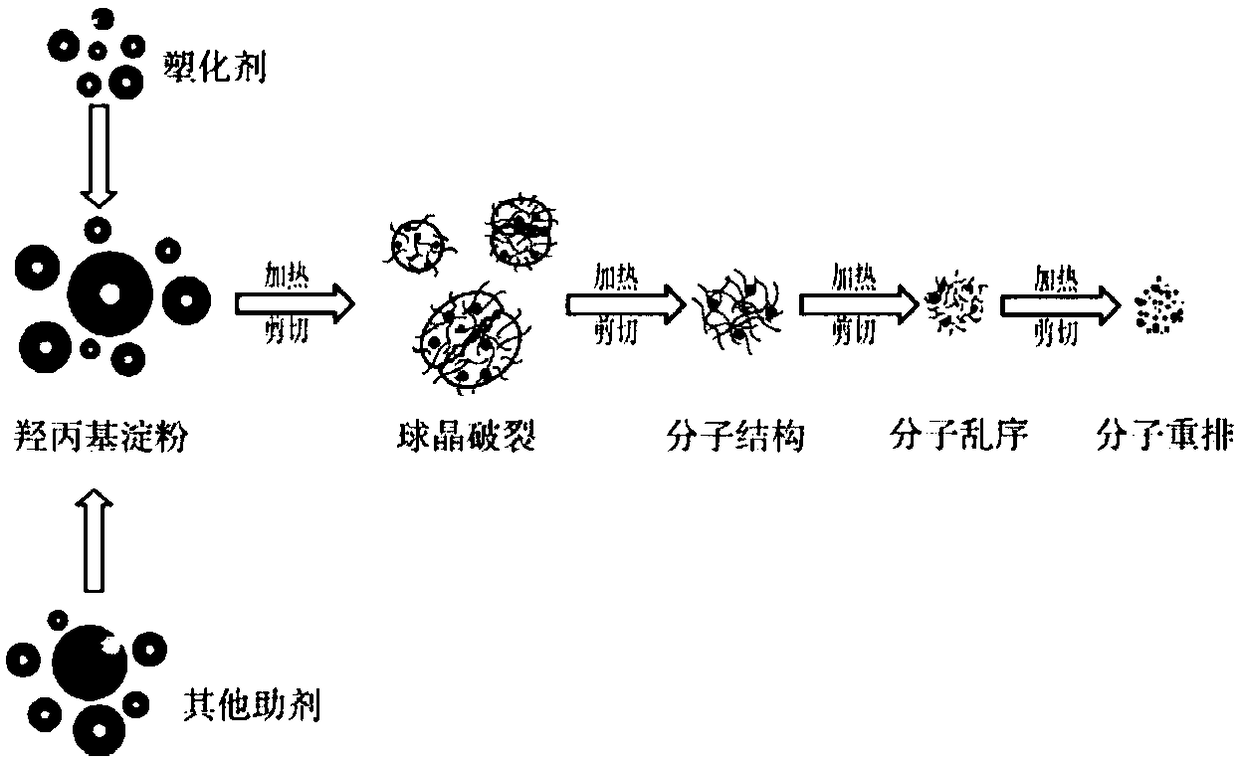

Method used

Image

Examples

Embodiment 1

[0032] (1) First, mix 20 parts of edible glycerin, 10 parts of deionized water, 2 parts of ferulic acid, 2 parts of pullulan and 1 part of lemongrass oil at 40°C, and gradually add 65 parts of hydroxypropyl corn starch.

[0033] (2) Mix the hydroxypropyl starch mixture thoroughly in a constant temperature water bath at 70° C. for 1 hour at 500 rpm with an overhead stirrer to prepare a starch mixture, and put it into a sealed polyethylene plastic bag to balance for one day and one night.

[0034] (3) Hot press the balanced hydroxypropyl starch mixture. The hot pressing process is as follows: first stage: 130°C, 2MPa, 1min; second stage: 140°C, 4MPa, 5min, to prepare modified thermoplastic hydroxypropyl starch starch film.

Embodiment 2

[0036] (1) First, 20 parts of edible glycerin, 10 parts of deionized water, 2 parts of magnesium chloride, 2 parts of pullulan and 1 part of lemongrass oil were mixed at 40°C, and 65 parts of hydroxypropyl waxed cornstarch were gradually added.

[0037] (2) The hydroxypropyl starch mixture was thoroughly mixed with an overhead stirrer in a constant temperature water bath at 75° C. at 600 rpm for 2 hours to prepare a starch mixture, which was placed in a sealed polyethylene plastic bag to balance for one day and one night.

[0038](3) Hot press the balanced hydroxypropyl starch mixture. The hot pressing process is as follows: first stage: 140°C, 2MPa, 1min; second stage: 150°C, 4MPa, 6min, to prepare modified thermoplastic hydroxypropyl starch starch film.

Embodiment 3

[0040] (1) First, 10 parts of edible glycerin, 15 parts of deionized water, 2 parts of ferulic acid, 2 parts of glucomannan and 1 part of lemongrass oil were mixed at 40°C, and 70 parts of hydroxypropyl tapioca starch was gradually added.

[0041] (2) The hydroxypropyl starch mixture was thoroughly mixed with an overhead stirrer in a constant temperature water bath at 80° C. at 700 rpm for 3 hours to prepare a starch mixture, which was placed in a sealed polyethylene plastic bag to balance for a day and a night.

[0042] (3) Hot press the balanced hydroxypropyl starch mixture. The hot pressing process is as follows: first stage: 130°C, 2MPa, 2min; second stage: 150°C, 6MPa, 5min, to prepare modified thermoplastic hydroxypropyl starch starch film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com