A kind of composite waterproof and moisture-permeable fabric and preparation method thereof

A waterproof and moisture-permeable fabric technology, applied in chemical instruments and methods, synthetic resin layered products, filament/thread molding, etc., can solve the problems of moisture-permeable function decline, blockage, etc., to improve waterproofness and simplify composite process , avoid the effect of fabric thickness and performance inhomogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The traditional fabric fabric is made of woven polyester-cotton plain weave fabric, and the fabric has been water-repellent finished, and the fabric is fixed on the surface of the receiving drum through double-sided adhesive tape;

[0039]Weigh a certain amount of polyurethane (PU), dissolve it in acetone / N-N dimethylformamide mixed solvent with a volume ratio of 1:3, stir magnetically for 2-3 hours, and obtain concentrations of 3wt%, 7wt%, and 11wt%, respectively. % and 15wt% spinning solution, stand-by;

[0040] Add the PU spinning solution into the liquid storage pipe in sequence according to the concentration gradient of 3wt%, 7wt%, 11wt%, and 15wt%, wherein the PU spinning solution with a concentration of 3wt% is close to the spinning needle;

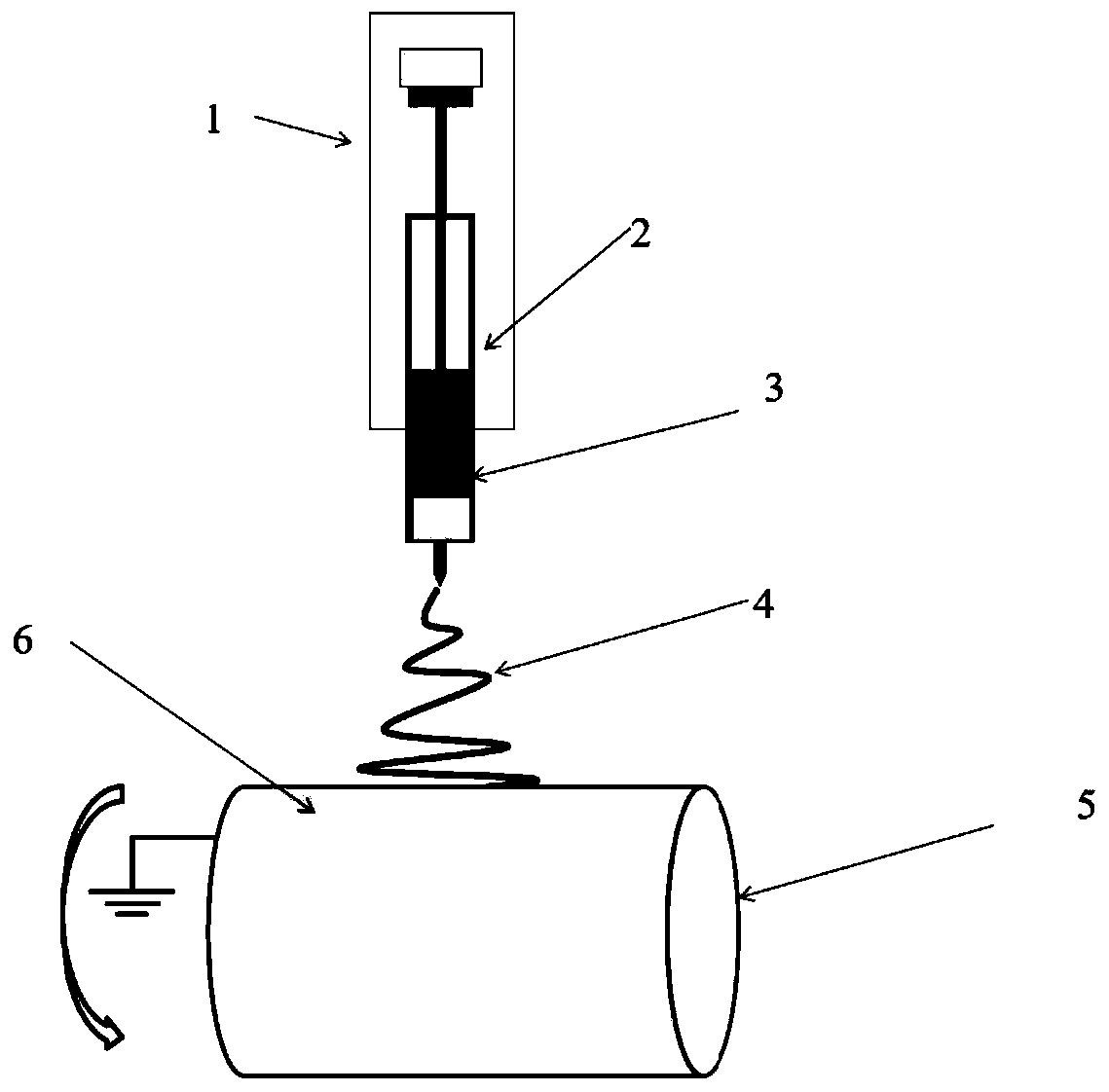

[0041] Adjust the positive voltage of the electrospinning device to +18kV, turn on the propeller and the drum, and push the spinning solution out of the storage tube at a speed of 2mL / h; among them, the inner diameter of the...

Embodiment 2

[0046] The traditional fabric fabric is made of woven polyester-cotton plain weave fabric, and the fabric has been water-repellent finished, and the fabric is fixed on the surface of the receiving drum through double-sided adhesive tape;

[0047] Weigh a certain amount of polyurethane (PU), dissolve it in acetone / N-N dimethylformamide mixed solvent with a volume ratio of 1:3, stir magnetically for 2-3 hours, and obtain concentrations of 2wt%, 6wt%, and 8wt%, respectively. % and 10wt% spinning solution, stand-by;

[0048] Adding the PU spinning solution into the liquid storage pipe sequentially according to the concentration gradient of 2wt%, 6wt%, 8wt%, and 10wt%, wherein the PU spinning solution with a concentration of 2wt% is close to the spinning needle;

[0049] Adjust the positive voltage of the electrospinning device to +18kV, turn on the propeller and the drum, and push the spinning solution out of the storage tube at a speed of 2mL / h; among them, the inner diameter of ...

Embodiment 3

[0054] The traditional fabric fabric is knitted hemp fabric, and the fabric is water-repellent, and the fabric is fixed on the surface of the receiving drum through double-sided adhesive tape;

[0055] A certain amount of polyvinylidene fluoride was weighed, dissolved in dimethyl sulfoxide, and magnetically stirred for 2 hours to obtain spinning solutions with concentrations of 3wt%, 6wt%, 10wt% and 15wt%, respectively, for use;

[0056] The polyvinylidene fluoride spinning solution is sequentially added into the liquid storage pipe according to the concentration gradient of 3wt%, 6wt%, 10wt%, and 15wt%, wherein the polyvinylidene fluoride spinning solution with a concentration of 3wt% is close to the spinning needle;

[0057] Adjust the positive voltage of the electrospinning device to +10kV, turn on the propeller and the drum, and push the spinning solution out of the storage tube at a speed of 3mL / h; among them, the inner diameter of the needle used for electrospinning is 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com