Novel PU side module structure

A modular structure, a new type of technology, applied in the direction of building components, building structures, buildings, etc., can solve the problems of composite panel tilting, etc., and achieve the effects of reduced processing costs, convenient replacement of modules, and reasonable position and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

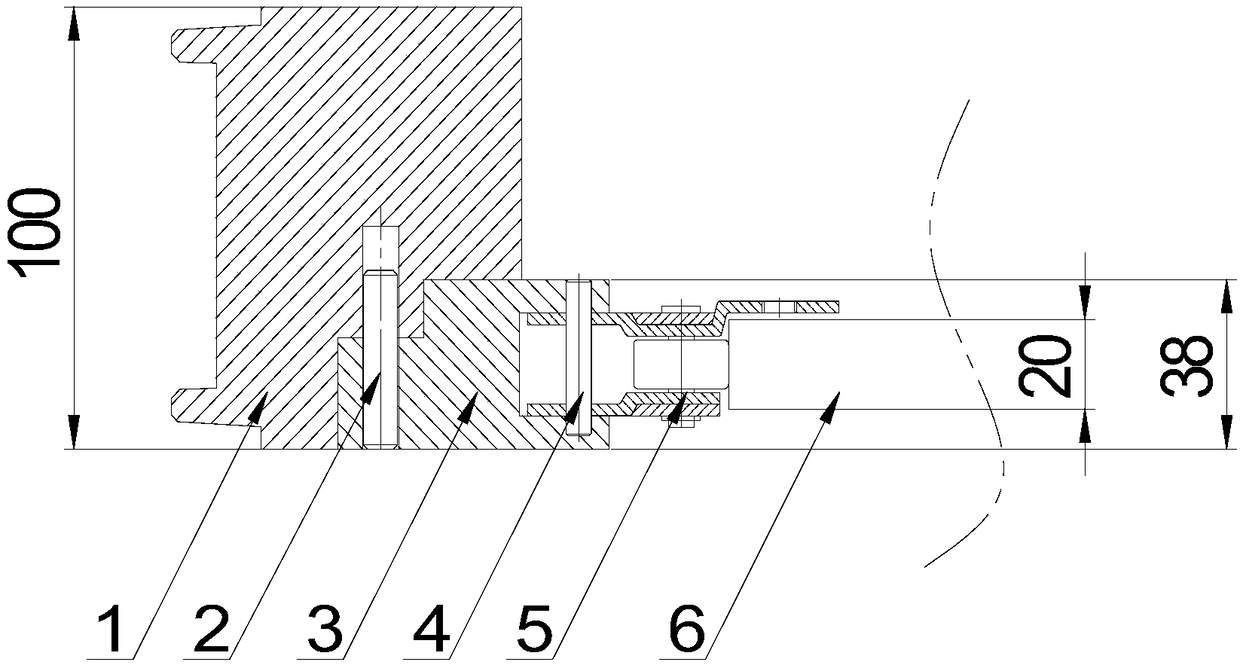

[0029] A new type of PU side module structure, the chain 5 is provided with a fixing block 9 for supporting the forming module 1, and the fixing block 9 is stuck between the chain pieces of the chain 5 and fixed on the chain 5; the forming module 1 and the fixing block There is a movable connecting piece between 9, and the molding module 1 is fixed on the fixed block 9 by this moving connecting piece.

[0030] The movable connector is a groove and a T-shaped positioning end that cooperate with each other; a groove is provided on the forming module, and fixed iron sheets 7 are arranged on both sides of the opening of the groove; a T-shaped positioning end is provided on the fixed block, and the T-shaped positioning end snaps into the In the groove, the position is limited by fixing the iron sheet.

specific Embodiment 2

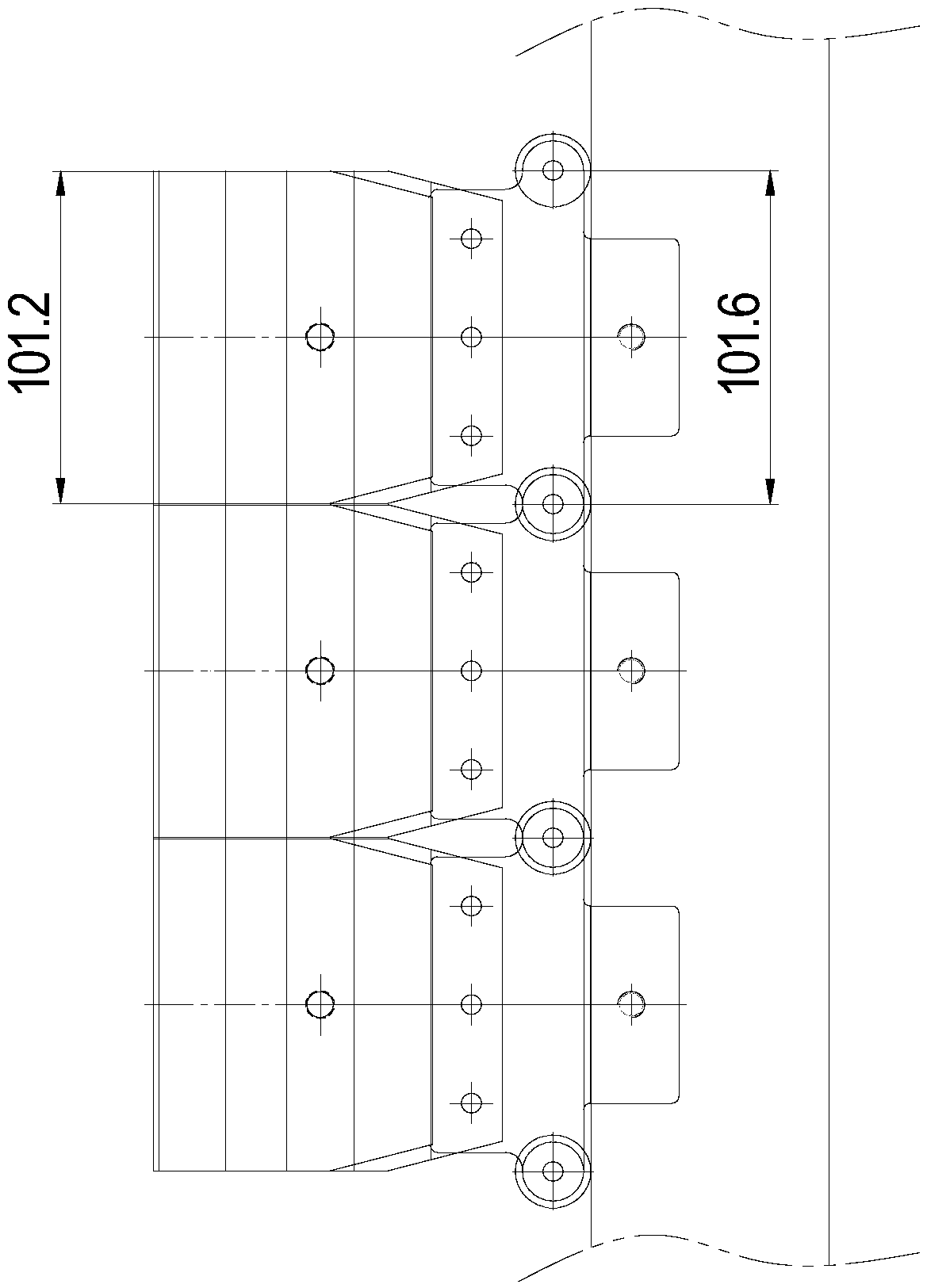

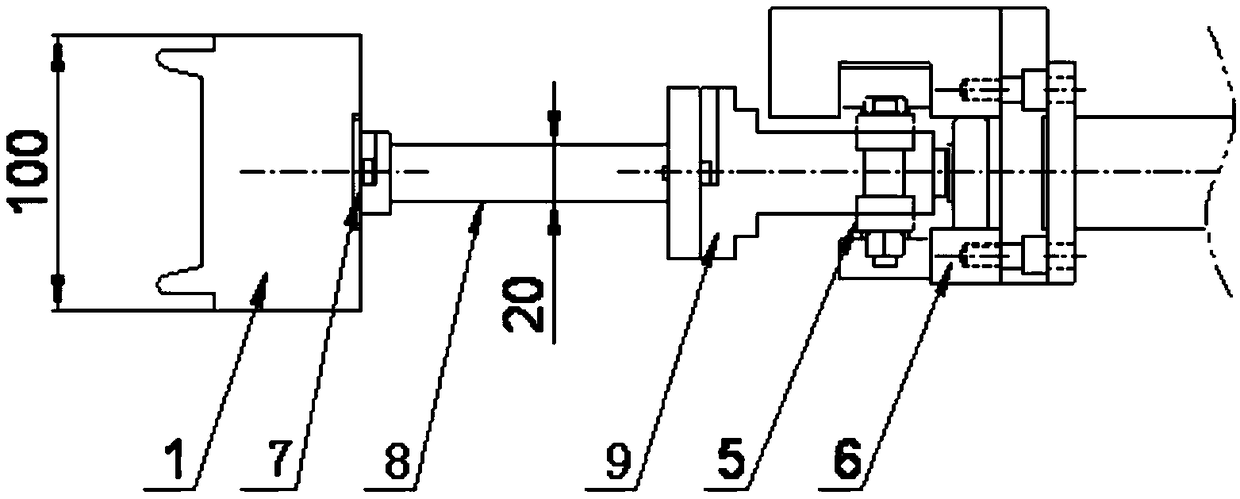

[0031] Specific embodiment two, such as image 3 , Figure 4 Shown:

[0032] A new type of PU side module structure, the chain 5 is provided with a fixing block 9 for supporting the forming module 1, and the fixing block 9 is clamped between the chain pieces of the chain 5 and fixed on the chain 5; between the forming module and the fixing block There is a module support arm 8 between them, and the module support arm 8 is movably connected with the forming module 1 and the fixed block 9 .

[0033] The active link structure is as Figure 5 , Figure 6 As shown, it is a groove and a T-shaped positioning structure 11 that cooperate with each other; grooves are provided on the molding module, and fixed iron sheets 7 are arranged on both sides of the groove opening, and the fixed iron sheets 7 are fixed on the molding module 1 by fixing screws 10, forming The module 1 and the fixed iron sheet 7 form a positioning slot, which can directly clamp the forming module 1 on the module...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com