Eight-axis mirror polishing machine tool

A mirror polishing and machine tool technology, applied in the field of polishing machine tools, can solve problems such as short circuit of electrical components, difficult quality control, and endangering the health of operators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

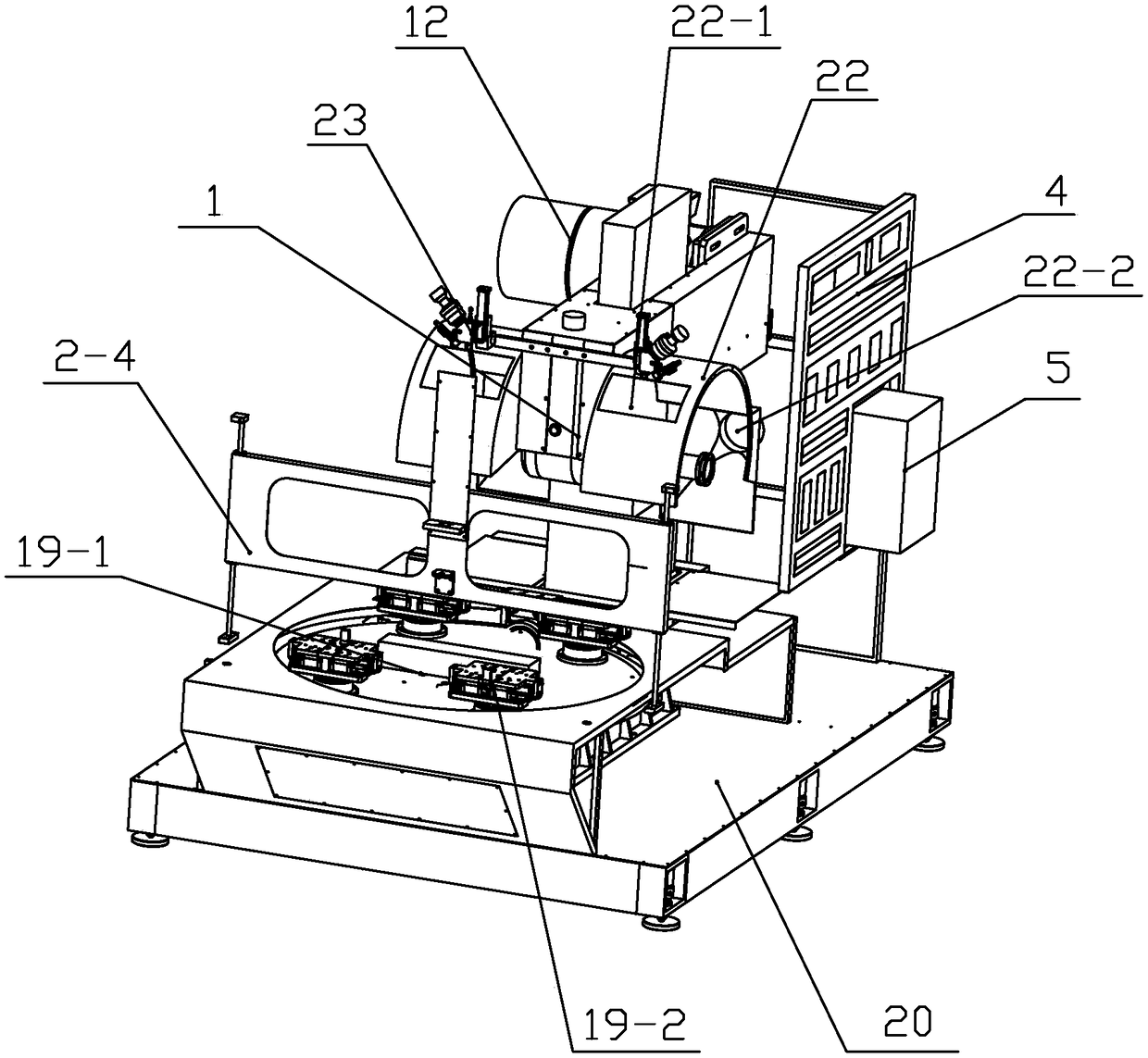

[0037] Specific implementation mode one: combine Figure 1-7 Describe this embodiment, an eight-axis mirror polishing machine tool, which includes a machine tool main body 1 and a housing 2 that is located outside the machine tool main body 1, the machine tool main body 1 includes a mounting frame 11, a spindle motor 12, a spindle gearbox 13, Throwing wheel, throwing shaft installation shaft 15, X-axis driving mechanism 16, Y-axis driving mechanism 17, Z-axis driving mechanism 18, fixture assembly 19 and base 20, of which Y-axis driving mechanism 17, Z-axis driving mechanism 18 and X-axis The driving mechanism 16 is arranged sequentially from top to bottom and is all arranged between the mounting frame 11 and the base 20. The main shaft motor 12 and the spindle gearbox 13 are fixedly connected to the two ends of the mounting frame 11 in the horizontal direction respectively. The output shaft of the main shaft gearbox 13 is fixedly connected by the throwing shaft installation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com