Milling cutter wear states monitoring method based on deep neural network

A deep neural network and wear state technology, applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems of limited application range and failure to achieve intelligence, so as to improve effectiveness, reduce impact, Effects of Overcoming Dependence on Signal Processing Techniques and Diagnostic Experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

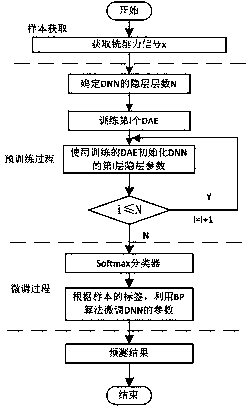

[0031] The steps of the milling cutter wear state monitoring method based on the deep neural network of the present invention are:

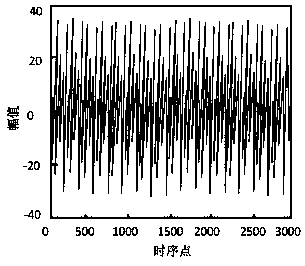

[0032] Step 1: Under a certain working condition, use constant cutting parameters to process the titanium alloy material, and the tool is milled 70 times on the side of the workpiece, and the Kistler9123C rotary dynamometer is used to measure the cutting force signal in the process, and at the same time Measure the flank wear state of the tool after each machining, and extract 50 groups of tool wear states as the output of the neural network for training;

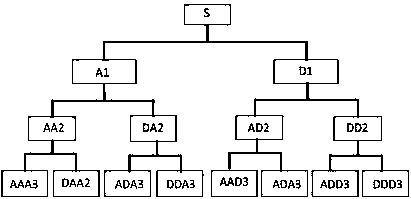

[0033] Step 2: Use six-layer wavelet packet analysis to decompose and reconstruct the filtered cutting force signal in the time-frequency domain, and use 64 sub-energy bands as cutting force features for subsequent DNN neural network training;

[0034] Step 3: Use the 50 sets of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com