Environment-friendly graphite lubricating releasing agent

A graphite lubrication and release agent technology, applied in the directions of casting mold, core, casting mold composition, etc., can solve the problems of unsatisfactory casting, surface flow marks, affecting the fluidity of non-ferrous metal liquid, etc., and achieve low cost, good lubrication and release. Mold performance, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

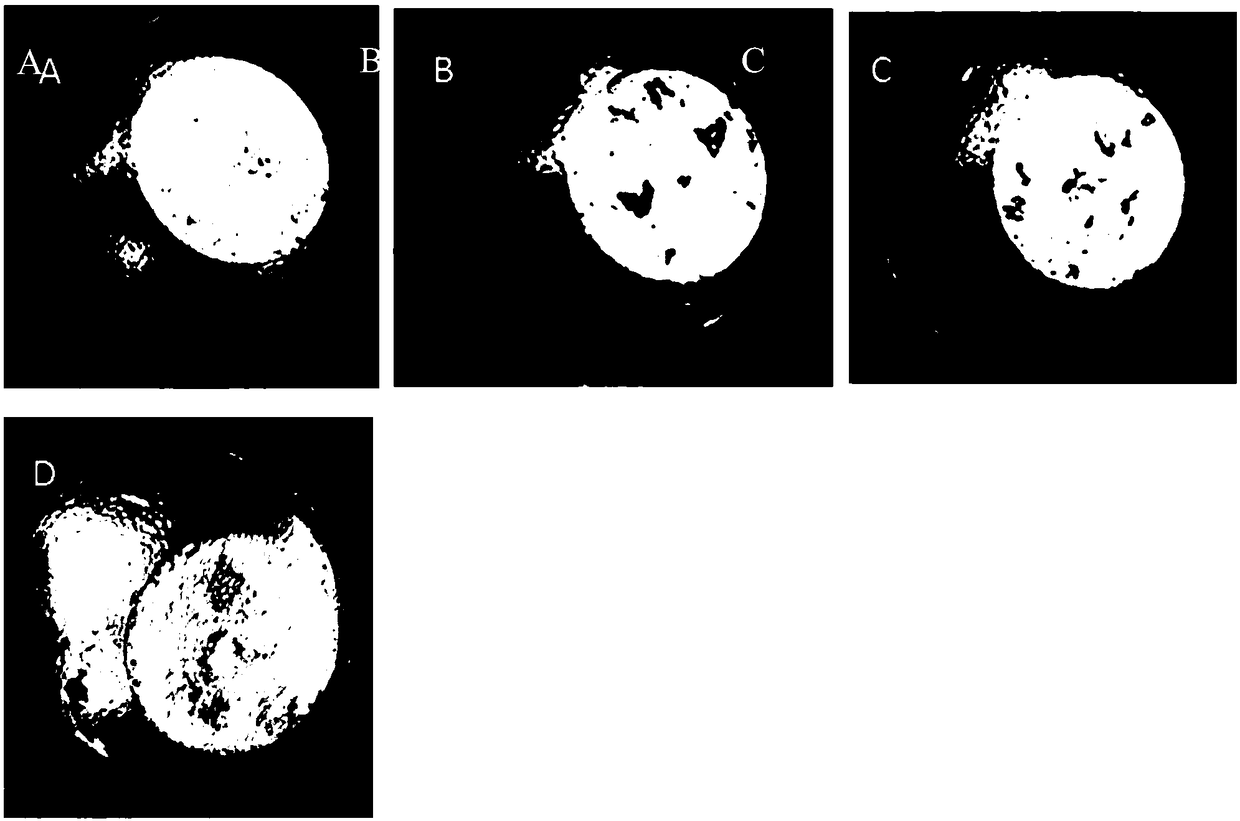

[0035] Example 1, a water-based graphite lubricating mold release agent, its composition and weight ratio: 90.0wt% of various graphites with the same particle size, 0.02wt% of organic dispersants, and 9.97wt% of inorganic fillers. And the water-based mold release agent of the present invention and the prior art were diluted with water to 20.0wt% slurry respectively, and were used for the gravity casting experiment of copper parts after being fully stirred. Table 1 investigates the influence of different types of graphite on the demoulding effect, casting quality and mold surface state; figure 1 Diagram of release castings prepared with water-based graphite-lubricated release agents for different types of graphite.

[0036] Table 1

[0037]

[0038] Table 1 and figure 1 The results show that the casting surface of the mold release agent of the present invention using graphite tailings for demoulding is smooth, the mold surface is smooth, and the mold release effect ...

Embodiment 2

[0039]Embodiment 2, a kind of water-based graphite lubricating release agent, its composition and weight percent are as shown in table 2, and water-based release agent of the present invention and prior art are diluted to 20% slurry respectively with water, fully After stirring, it is used for the gravity casting experiment of copper parts.

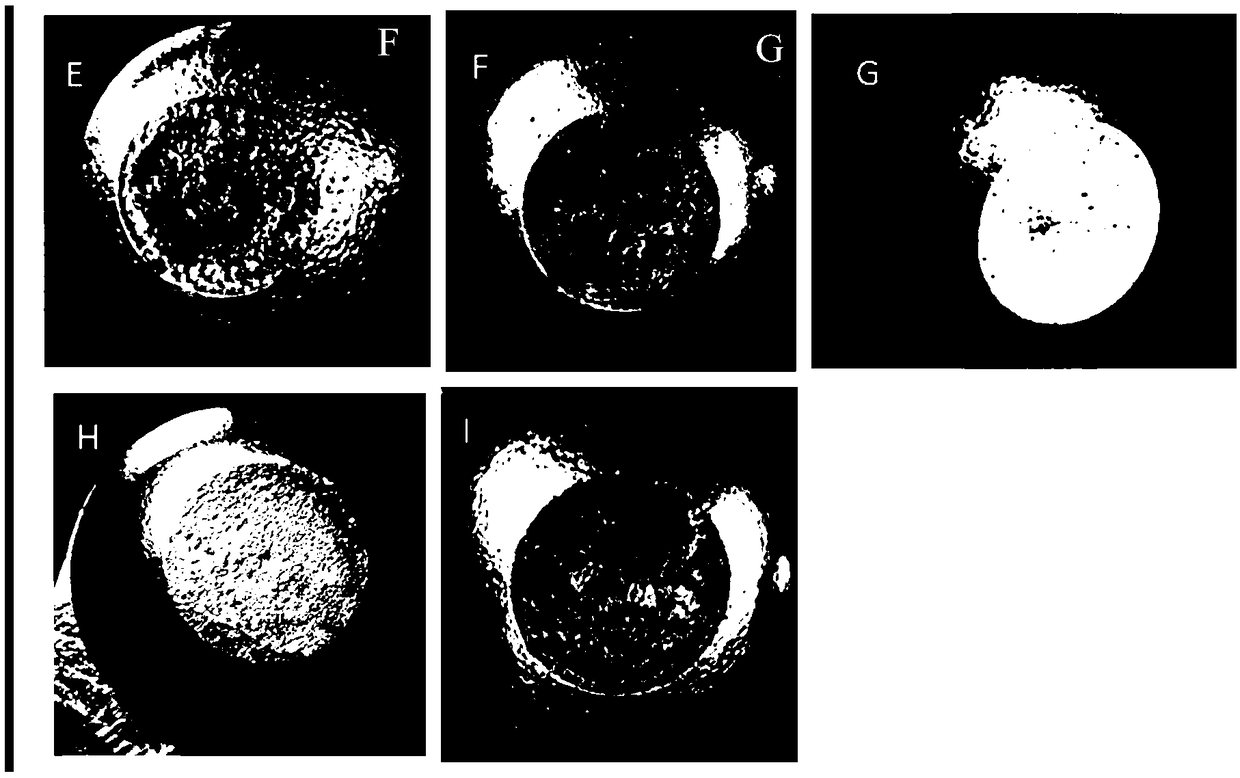

[0040] Table 2 investigates the influence of different dosages of graphite tailings on the demoulding effect, casting quality and mold surface state; figure 2 Diagram of release castings prepared with water-based graphite-lubricated release agents for different graphite tailing contents.

[0041] Table 2:

[0042]

[0043] Table 2 and figure 2 The results show that using the release agent of the present invention, when the proportion of graphite tailings in the release agent is 85-90wt%, the casting surface is smooth, the mold surface is flat, free of mold scale, and the release effect is optimal. Using the release agent of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com