A water-based graphite lubricating release agent

A technology of graphite lubrication and mold release agent, which is applied in the direction of coating, casting molding equipment, casting molds, etc., which can solve the problems of liquid metal temperature rise, mold wear and shortening service life, etc., to achieve smooth castings and reduce mold Effect of wear and delay of die life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

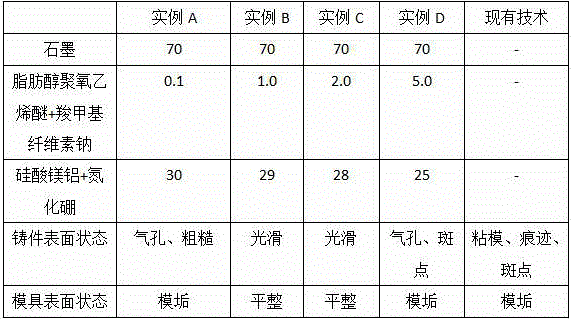

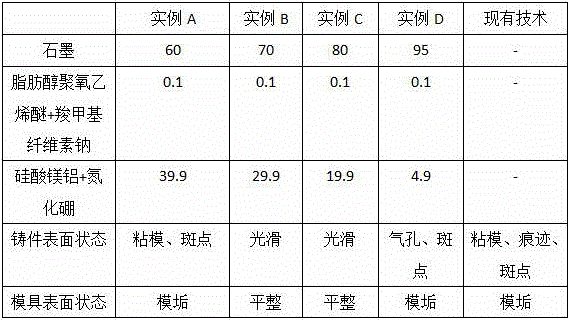

[0025] Embodiment 1, a kind of water-based graphite lubricating release agent, its composition and weight are as shown in Table 1, and water-based release agent of the present invention and prior art are respectively diluted to 20% slurry with water, fully stirred Later, it was used in the gravity casting experiment of copper parts. Table 1 examines the influence of different proportions of graphite and inorganic dispersants on the release effect; Table 2 examines the influence of organic dispersants on the release effect.

[0026] Table 1:

[0027]

[0028] Table 2

[0029]

[0030] Table 1 result shows, use mold release agent of the present invention, the proportion of the graphite of mold release agent is 70-80wt%, when inorganic dispersant ratio is 20-30wt%, casting surface is smooth, and mold surface is flat, without mold scale, demoulding Best results. Using the release agent of the prior art, mold sticking, traces and spots on the surface of the casting; mold s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com