Mold for achieving in-mold rapid forming and quenching

A mold and solid technology, applied in the direction of forming tools, quenching devices, manufacturing tools, etc., can solve the problems of mutual influence, affecting the forming performance of sheet metal, and the rapid drop of local temperature of hot metal slabs, etc., to achieve small heat capacity, skin thin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

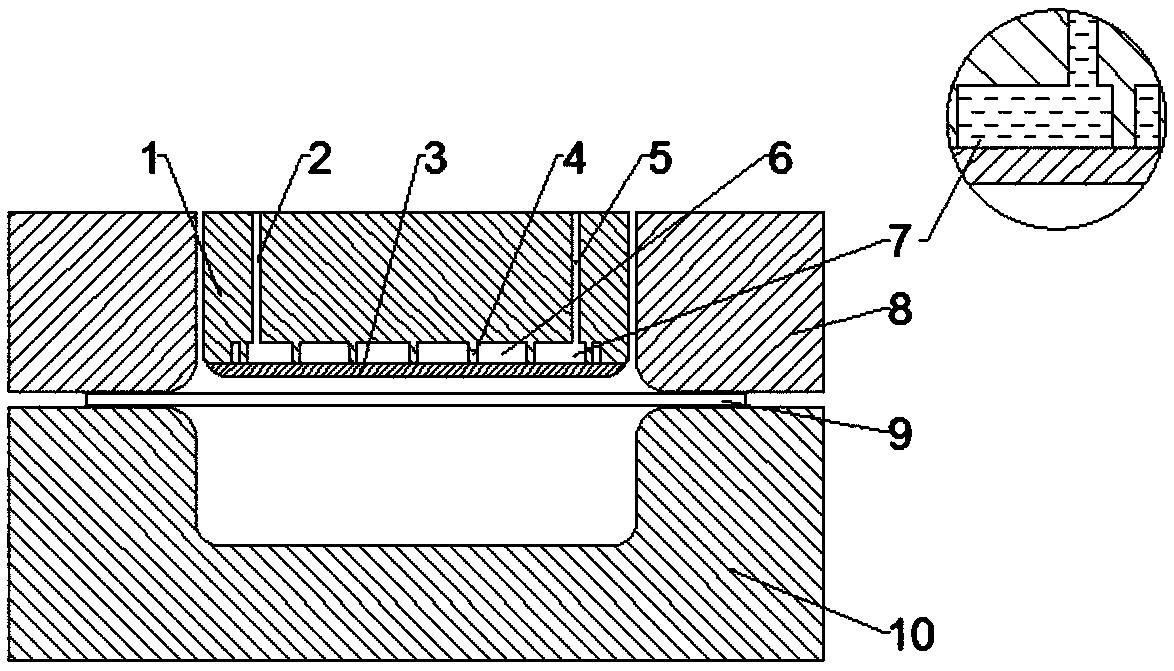

[0038] combine figure 1 And Fig. 2 illustrates, a kind of mold that realizes in-mold rapid prototyping and quenching, (1) forming mold comprises upper mold and lower mold, and lower mold is a traditional overall structure; The thin-walled skin is tightly wrapped on the internal solid core; (3) The shape and size of the outer surface of the thin-walled skin are the same as the shape and size of the part; (4) The surface of the internal solid core is provided with vertical ribs and mutual Connected grooves, thin-walled skins and grooves form specific channels after contact; (5) Medium inlet holes and outlet holes are provided on the internal solid core, and are connected to the channels formed by the skin and grooves.

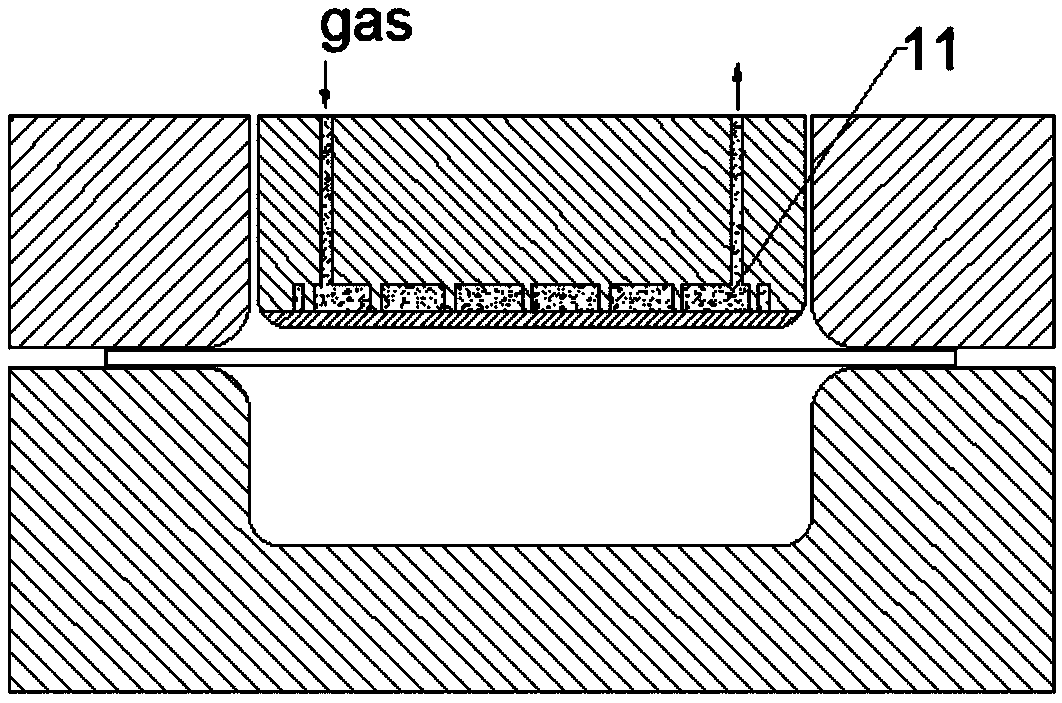

[0039] The above-mentioned mold for realizing rapid forming and quenching in the mold, its working process is carried out according to the following steps:

[0040] Step 1. According to the material type, complexity, precision requirements, etc. of the metal she...

Embodiment 2

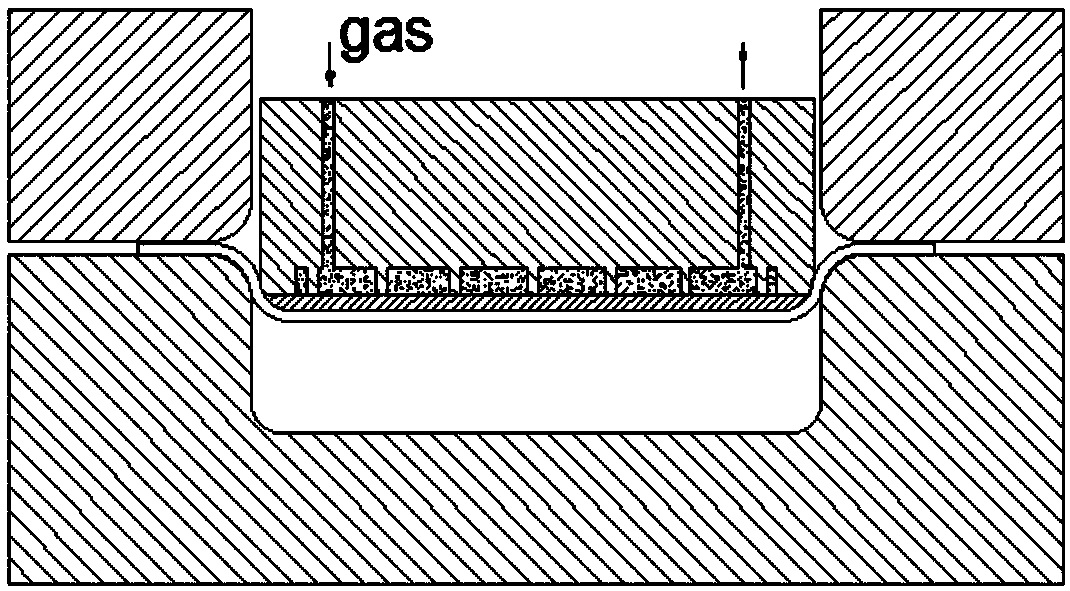

[0048] combine image 3 And Fig. 4 illustrates, another kind of mold that realizes rapid prototyping and quenching in the mold, (1) forming mold comprises upper mold and lower mold, and upper mold and lower mold are all composite structures; (2) upper mold and lower mold are all made of The thin-walled skin and the internal solid mold core are composed, and the thin-walled skin is tightly wrapped on the internal solid mold core; (3) the shape and size of the outer surface of the thin-walled skin are the same as the shape and size of the part; (4) the surface of the internal solid mold core is provided with Ribs and interconnected grooves, the thin-walled skin and the grooves contact to form a specific channel; (5) There are medium inlet holes and outlet holes on the internal solid mold core, which are connected to the channel formed by the skin and grooves. connect.

[0049] The working process of the above-mentioned mold for rapid forming and quenching in the mold is the sam...

Embodiment 3

[0051] Example Three: Combining figure 1 As shown in Fig. 4, a mold for realizing rapid prototyping and quenching in the mold, in step 1, the thin-walled skin in the combined mold adopts a metal sheet with good thermal conductivity, small heat capacity, high strength, and wear resistance, such as a stainless steel plate , high-temperature alloy plate or titanium alloy plate, etc., the thickness of the thin-walled skin is 0.2-0.5mm, and the thin-walled skin is in close contact with the vertical ribs of the internal solid mold core and does not deform during the contact process with the metal slab. Others are the same as the first and second embodiments.

[0052] Due to the thin wall thickness and small heat capacity of the skin, during the forming stage, when the hot metal slab contacts the skin, the temperature of the skin will rise quickly but will not conduct much away from the hot metal slab The heat will not cause the temperature of the hot metal slab to drop rapidly. Ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com