Medium-high fluorine slag system for electroslag remelting of B-containing rotor steel ingot and use method

A technology for electroslag remelting and rotor steel, applied in the field of electroslag special metallurgy, can solve the problems of high fluorine slag volatilization pollution and high energy consumption, and achieve the effects of reducing volatilization pollution, good surface quality and easy arc starting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] In another aspect, the present invention provides a method for preparing medium-high fluorine slag system, comprising the following steps:

[0056] Step 1: For commercially pure CaF 2 After high-temperature baking, it is ready for use;

[0057] Step 2: Use commercially pure CaF 2 , CaO, Al 2 o 3 , MgO, B 2 o 3 Prepare the slag system according to the mass percentage of the target slag system composition, and dry it for later use;

[0058] Step 3: heating and melting the melting point of the prepared slag system to obtain a molten slag product;

[0059] Step 4: Sprinkle water on the produced molten slag product, cool it, and break it into 8-15mm massive pre-melted slag for later use.

[0060] It should be noted that, in the above-mentioned step 1, considering factors such as environmental humidity may exist in the processing, production and transportation of industrial raw materials, it is necessary to use industrially pure CaF 2 Baking at a high temperature of 8...

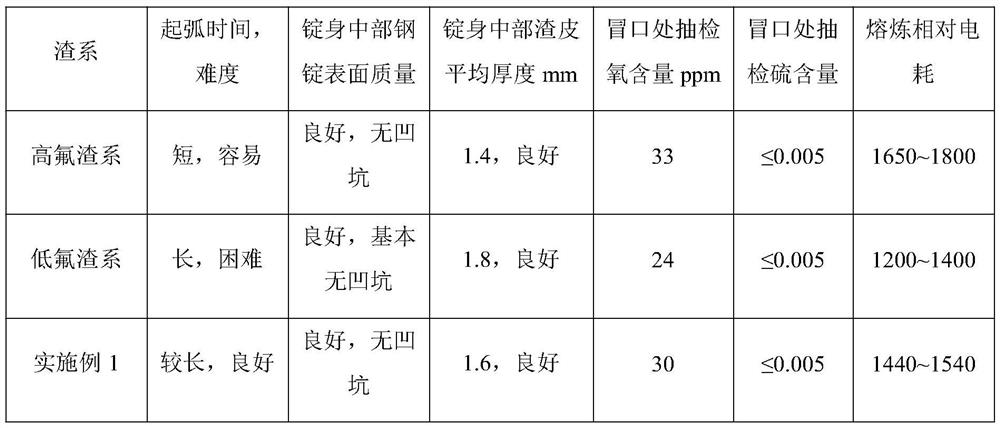

Embodiment 1

[0073] This example provides a medium-high fluorine slag system for electroslag remelting of B-containing rotor steel ingots. The mass percentage of each component in the slag system is: CaF 2 ; 40.26%, Al 2 o 3 : 33.99%, CaO; 22.25%, MgO: 3%, B 2 o 3 : 0.5%, the rest is impurities; SiO in impurities 2 The mass percentage content of <0.5%.

[0074] The basic physical properties of the slag in this example are: melting point 1331°C, density range 2.67-2.70g / cm at 1600°C-1800°C 3 , the viscosity is 0.011~0.021Pa·s, and the conductivity range is 1.58~2.36S / cm.

[0075] The preparation method of the slag system comprises the steps of:

[0076] Step 1: Considering factors such as the processing, production, and transportation of industrial raw materials that may have a humid environment, the industrially pure CaF 2 Bake at 820°C for 3 hours for later use, in order to remove moisture and impurities;

[0077] Step 2: Use commercially pure CaF 2 , CaO, Al 2 o 3 , MgO, B 2 ...

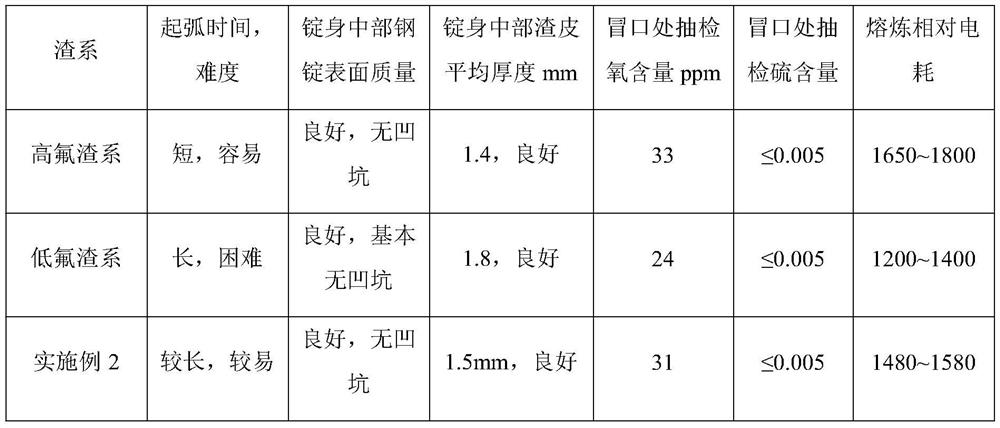

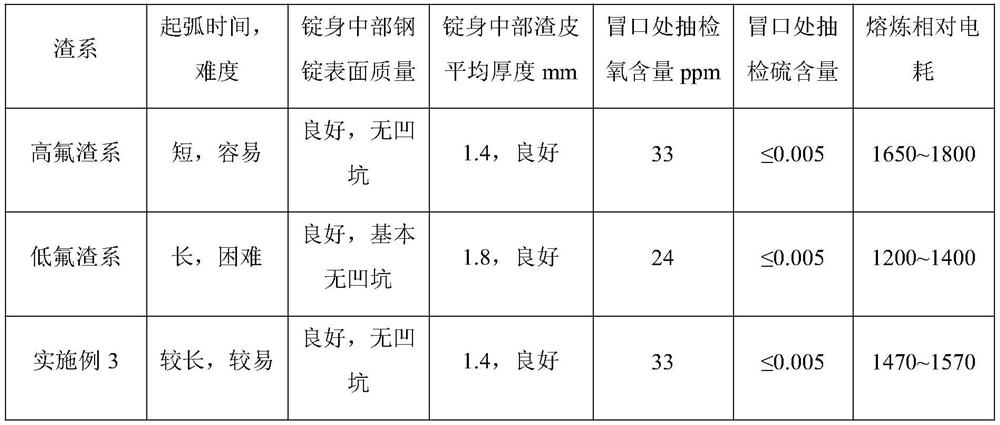

Embodiment 2

[0087] This example provides a medium-high fluorine slag system for electroslag remelting of B-containing 9Cr rotor steel ingots. The mass percentage of each component in the slag system is: CaF 2 ;46.79%, Al 2 o 3 : 23.56%, CaO; 24.15%, MgO: 5%, B 2 o 3 : 0.5%, the rest is impurities; SiO in impurities 2 The mass percentage content is <0.5%.

[0088] The basic physical properties of the slag in this example are: the melting point is 1327°C, and the density ranges from about 2.60 to 2.64g / cm at 1600°C to 1800°C. 3 , the viscosity is about 0.007~0.014Pa·s, and the conductivity range is 2.25~3.03S / cm.

[0089] The preparation method of the slag system comprises the steps of:

[0090] Step 1: Considering factors such as the processing, production, and transportation of industrial raw materials that may have a humid environment, the industrially pure CaF 2 Bake at 820°C for 3 hours for later use, in order to remove moisture and impurities;

[0091] Step 2: Use commercially...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com