Soybean sieving machine

A screening machine, soybean technology, applied in the direction of sieve, solid separation, grille, etc., can solve the problems of high screening cost, noise, large area and energy consumption, poor screening effect, etc., to achieve low screening cost , Improve the screening effect and balance the screening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

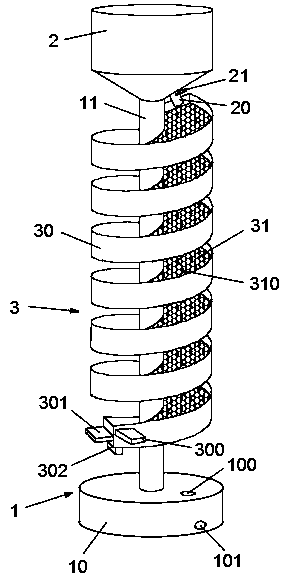

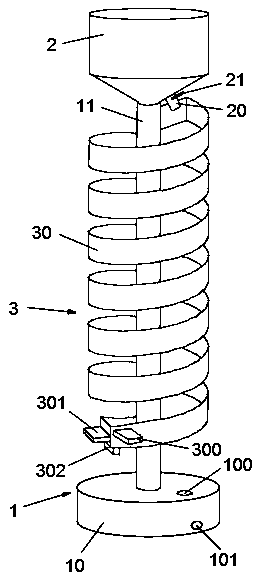

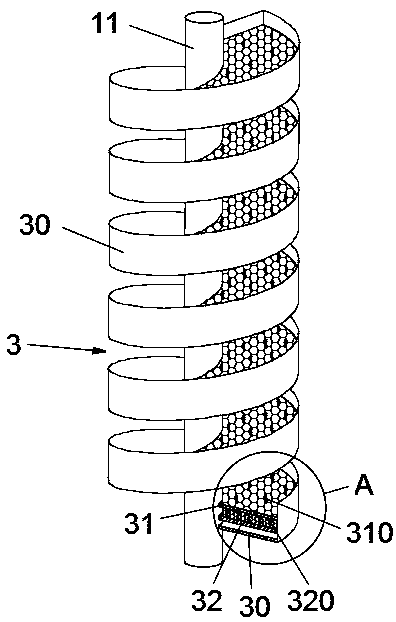

[0028] see Figure 1 to Figure 6 , a soybean screening machine, comprising a frame 1, a lower bin 2 and a screening main body 3; the frame 1 includes a base 10 and a vertical pole 11 fixed to the upper end of the base 10; the lower bin 2 is fixed On the upper end of the vertical rod 11; the screening main body 3 includes a spiral screening groove 30 longitudinally fixed outside the vertical rod 11; the spiral screening groove 30 is provided with a stage for screening out large impurities at intervals from top to bottom The screen 31 and the secondary screen 32 used to screen out small impurities, the primary screen 31 and the secondary screen 32 divide the spiral screening tank 30 into three layers from top to bottom; the primary screen 31 The aperture is greater than the aperture of the secondary screen 32; the lower end of the lower bin 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com