Efficient stirring reaction kettle for chemical production

A stirred reactor and chemical production technology, which is applied in the field of high-efficiency stirred reactors for chemical production, can solve the problems that materials cannot be fully turned, low mixing efficiency of chemical materials, and insufficient reaction process, etc., to achieve the promotion of stirring and mixing, Stirring efficiency is high, and the effect of promoting sufficient stirring action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

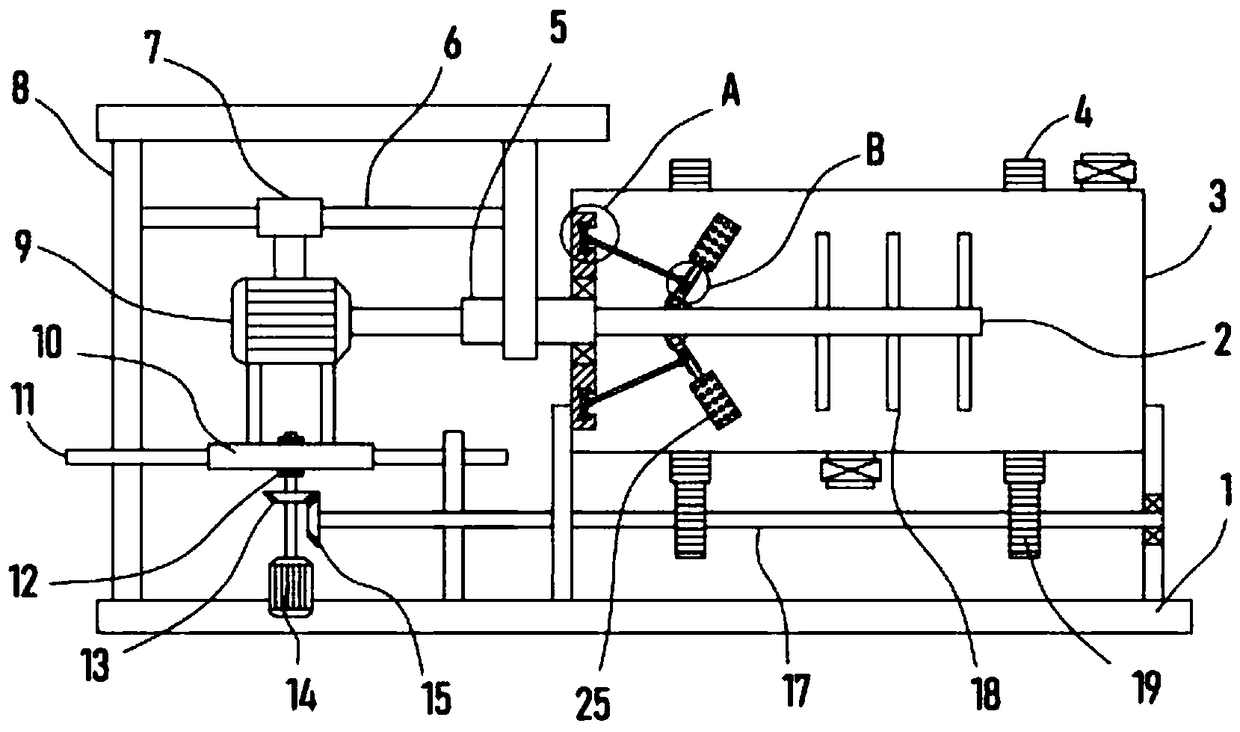

[0022] see Figure 1-4 , a high-efficiency stirring reactor for chemical production, comprising a support plate 1, a support frame 8 is fixedly installed on the support plate 1, a kettle body 3 is rotatably arranged on the support frame 8, and a stirring motor 9 is installed on the support frame 8 , the output shaft of the stirring motor 9 is coaxially fixed with the stirring shaft 2 extending into the kettle body 3, the surface of the stirring shaft 2 is evenly fixed with several stirring rods 18, the left end of the kettle body 3 is pivotally connected with a casing 5, and the stirring shaft 2 runs through Casing 5 is set.

[0023] The kettle body 3 is used to store the chemical materials to be stirred and mixed. The stirring shaft 2 is driven to rotate by the stirring motor 9, and the stirring shaft 2 drives the stirring rod 18 to rotate, thereby realizing the stirring effect of the materials in the kettle body 3, and promoting the composition of the materials. Fusion, imp...

Embodiment 2

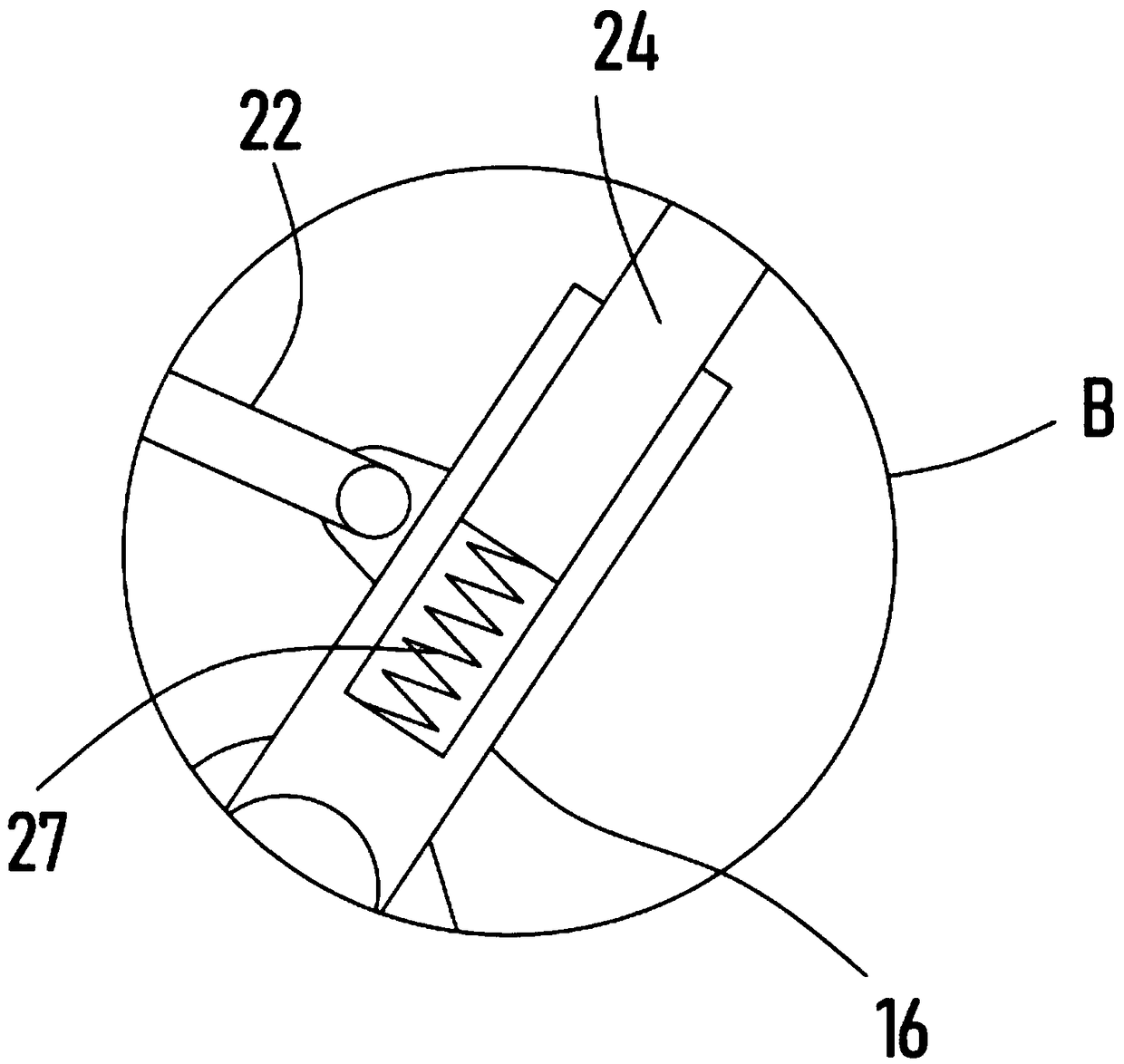

[0030] On the basis of Embodiment 1, in addition, the side wall of the stirring shaft 2 is hinged with a sleeve 16, and a telescopic rod 24 is slidably installed on the sleeve 16. The rotation drives the sleeve 16 to rotate together with the telescopic rod 24, and the telescopic rod 24 drives the stirring net plate 25 to further stir the materials in the kettle body 3.

[0031] Further, a spring 27 is installed in the sleeve 16 , one end of the spring 27 is fixed in the sleeve 16 , and the other end of the spring 27 is fixed at the end of the telescopic rod 24 inside the sleeve 16 . Under the elasticity of the spring 27, changing the rotating speed of the stirring motor 9 can realize the sliding of the telescopic rod 24 relative to the sleeve 16 under the limit action of the spring 27, so that the stirring degree of the material in the kettle body 3 is adjusted.

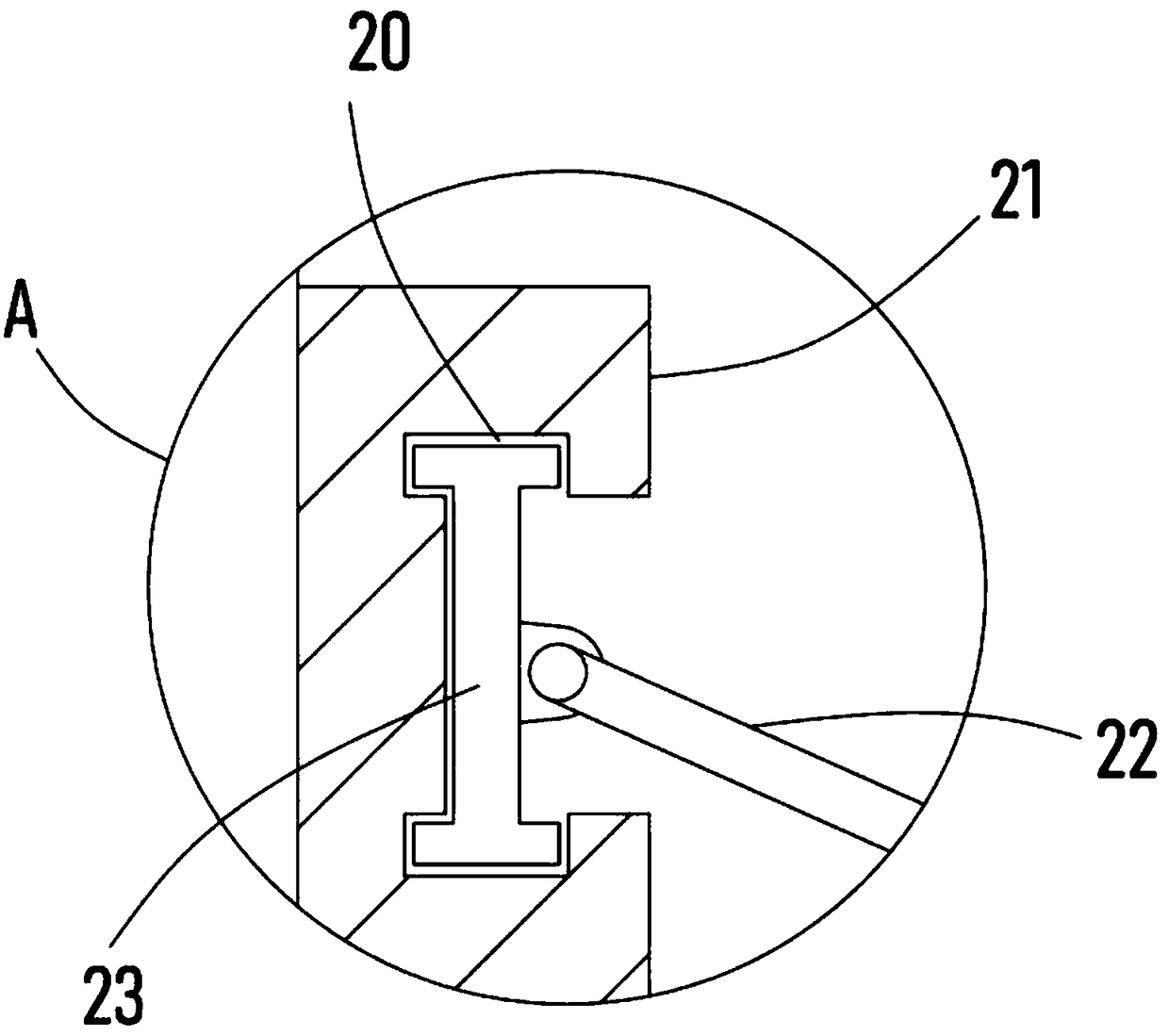

[0032] Further, the kettle body 3 is fixed with a fixed plate 21, and the inner circle of the fixed plate 21 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com