Oil fume purification equipment

A technology for oil fume purification and equipment, which is applied to chemical instruments and methods, separation of dispersed particles, combined devices, etc., can solve the problems of affecting human health, polluting the environment, and the purification effect depends on vertical honeycomb electric field devices, etc., to achieve good cleaning effect, Good purification effect and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings to make the technical solution of the present invention easier to understand and grasp.

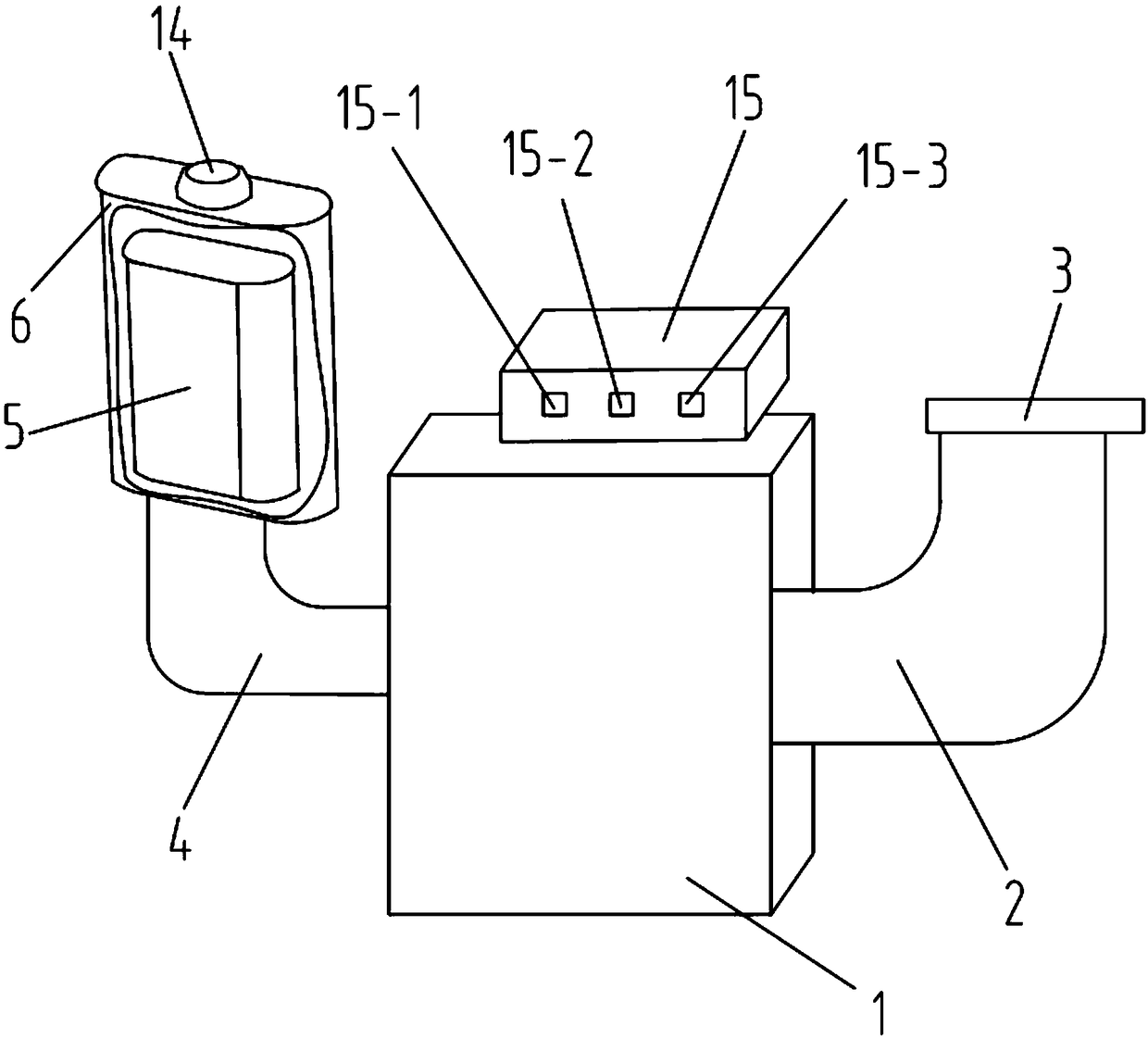

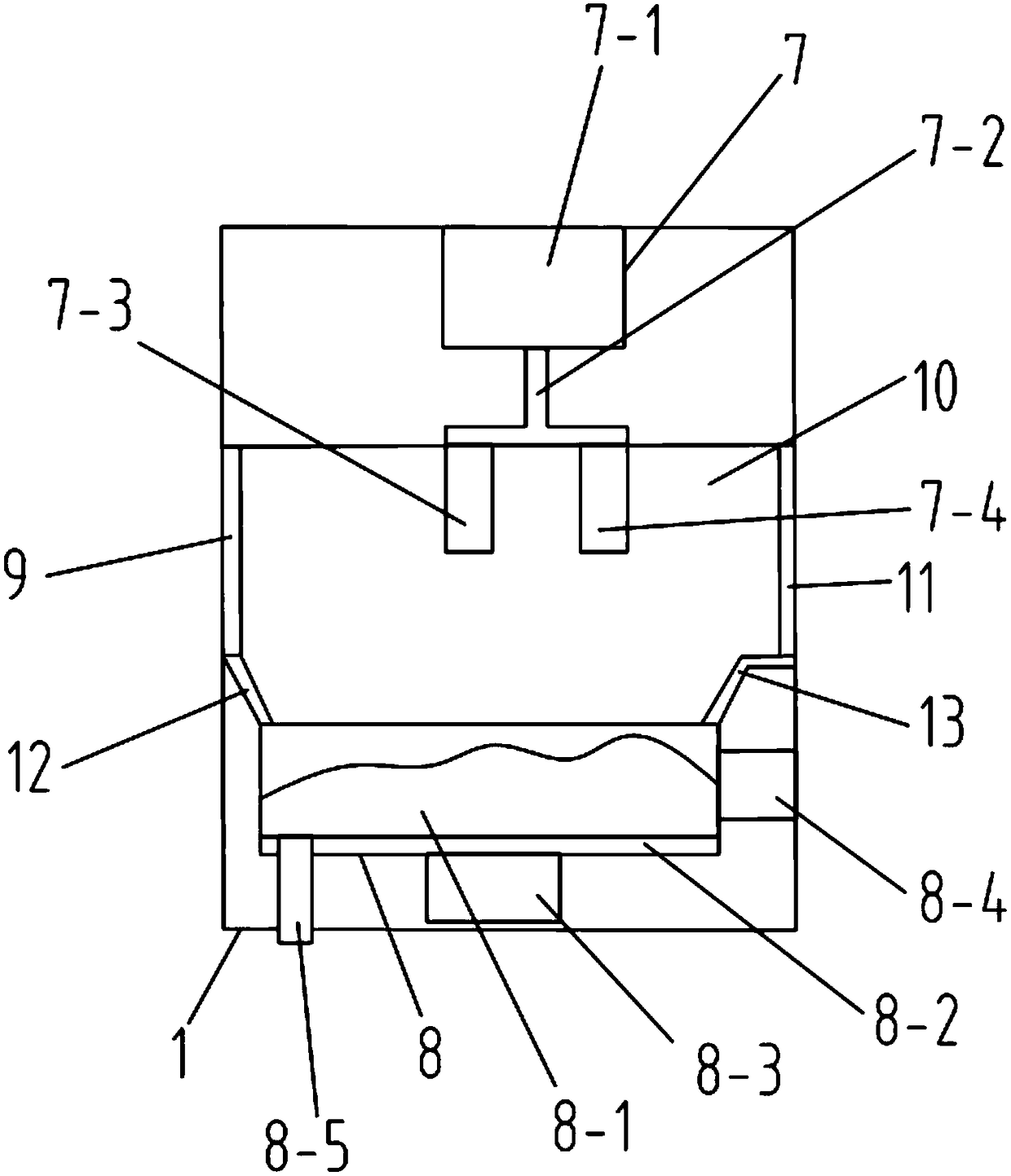

[0019] Such as figure 1 As shown in —2, an oil fume purification equipment includes a housing 1, an oil fume pipe 2 and an oil fume port 3. The oil fume port 3 is in communication with the oil fume pipe 2, and the oil fume pipe 2 is fixedly connected to the housing 1. The left end of the housing 1 is provided with a connecting pipe 4, an oil separation core 5 and an oil and gas tank 6, the oil and gas tank 6 is sleeved on the oil separation core 5, the oil separation core 5 is in communication with the connecting pipe 4, and the connecting pipe 4 is connected to the The housing 1 is fixedly connected, and an electrostatic degreasing assembly 7 and an ultrasonic degreasing assembly 8 are arranged in the housing 1. The ultrasonic degreasing assembly 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com