A tracked fire fighting robot

A fire-fighting robot and crawler-type technology, applied in the field of robots, can solve the problems of insufficient load capacity of fire-fighting robots, low fire-fighting efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

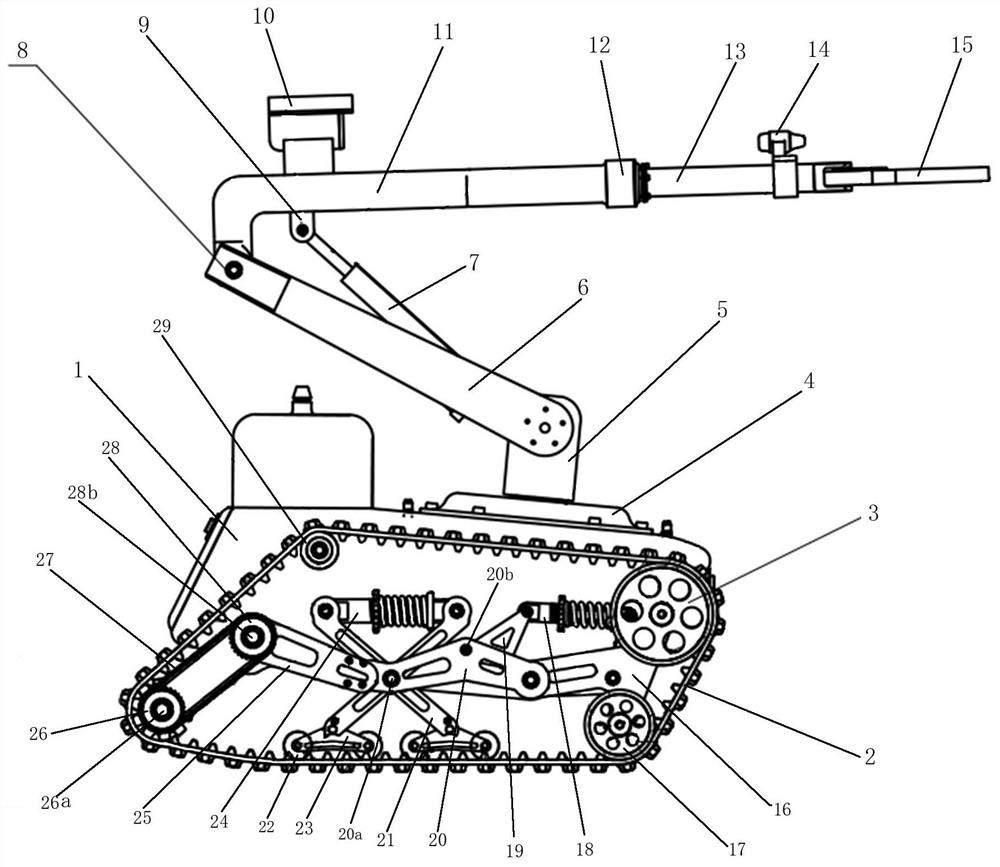

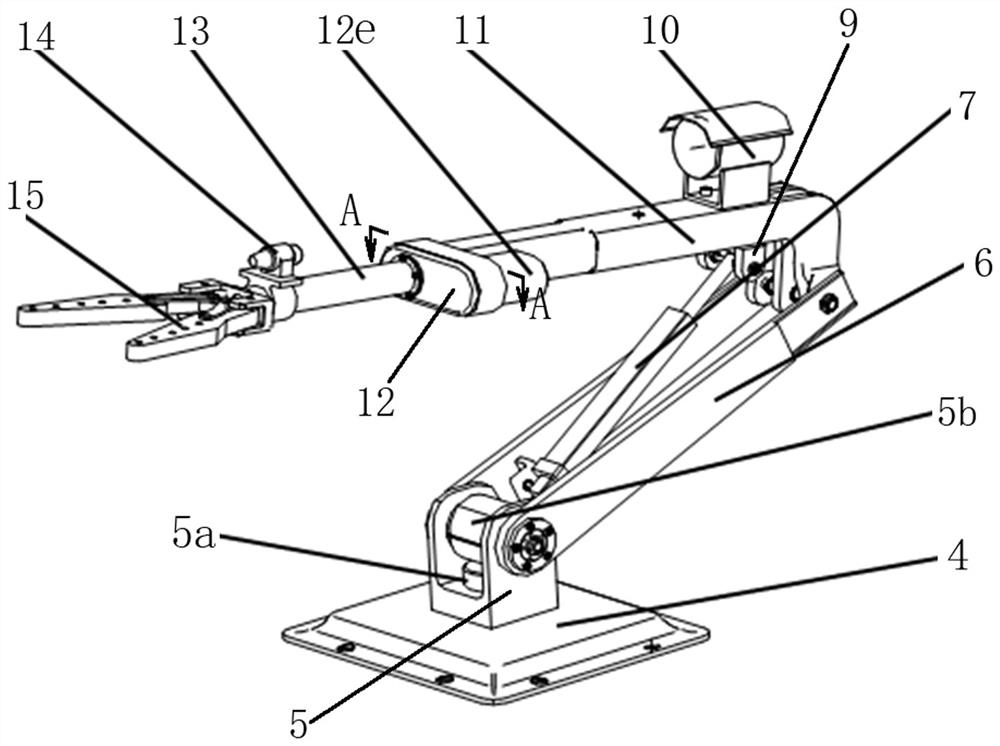

[0032] Such as figure 1 As shown, a crawler-type fire extinguishing robot provided by the present invention includes a housing 1, on which a mechanical arm rescue fire extinguishing device is arranged, and on both sides of the housing 1, crawler belts 2, crawler belt driving devices, and crawler belt supporting weights are respectively provided. device and track tension buffer device,

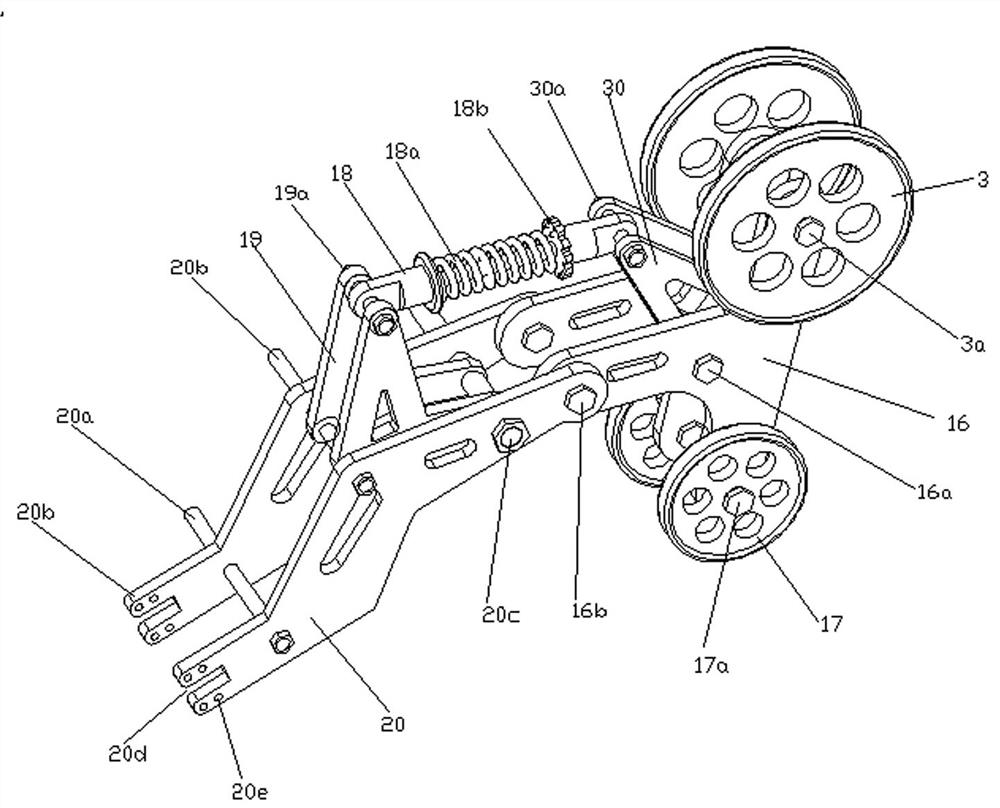

[0033] One, such as figure 1 , Figure 6 As shown, the crawler drive includes:

[0034] a. A power shaft 28b and its corresponding sprocket connecting plate 28c are respectively connected to the lower sides of the rear of the housing 1. Each power shaft extends into the housing 1 and connects with the drive motor, and each power shaft 28b extends out of the housing. And link a sprocket 28, connect chain 27 on each sprocket, connect driven shaft 26a below each sprocket connecting plate 28c, one side of driven shaft 26a connects driven sprocket 26, the other side connects with track Cooperati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com