A kind of method that gold catalyst catalyzes the oxidation prenyl alcohol to prepare prenyl aldehyde

A technology for producing prenyl aldehyde and gold catalysts from prenol, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., and can solve poor selectivity and environmental problems Problems such as serious pollution and low yield of prenaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Catalyst support preparation: modify the alumina support by the equal volume impregnation method to obtain a series of alumina supports modified by alkali metal or alkaline earth metal oxides: Na / Al 2 o 3 , Mg / Al 2 o 3 , K / Al 2 o 3 , Ca / Al 2 o 3 ,La / Al 2 o 3 ,Zn / Al 2 o 3 , etc., the loading of additives in the catalyst is 0.01% to 5%.

[0011] Catalyst preparation: prepare nano-gold particles with a particle size of about 2.0nm by colloidal method, then load the gold colloid on the modified alumina carrier under the condition of stirring, filter and wash, and vacuum-dry. Baking at 350 degrees in air for 4 hours to remove ligands. A series of nano-gold catalysts with different loads were obtained. The loading of gold is 0.1%-5%.

Embodiment 2

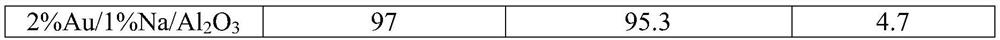

[0013] Catalytic conversion experiment: The prenol oxidation experiment was carried out in a stainless steel tube reactor with an inner diameter of 6 mm. The catalyst was a sodium-modified alumina-supported gold catalyst with a filling volume of 1 ml and an enol flow rate of 0.05 ml / min. The air flow rate was 24ml / min, and the reaction temperature was 250°C. Before the reaction, prenol is preheated through a 180-degree preheating furnace and then passes through the reactor. Utilize gas chromatography after the reaction to carry out product qualitative and quantitative analysis (Table 1), can see that the addition of sodium can improve the selectivity of product from the table, when sodium content is 1.5%, the selectivity of product is the highest is 99.4%.

Embodiment 3

[0015] Catalytic conversion experiment: Prenyl alcohol oxidation experiment was carried out in a stainless steel tube reactor with an inner diameter of 6 mm. The catalyst was a magnesium-modified alumina-supported gold catalyst with a filling volume of 1 ml and an enol flow rate of 0.05 ml / min. The air flow rate was 24ml / min, and the reaction temperature was 250°C. Before the reaction, prenol is preheated through a 180-degree preheating furnace and then passes through the reactor. After the reaction, the qualitative and quantitative analysis of the product was carried out by gas chromatography (Table 2). It can be seen that the modification of magnesium can also improve the selectivity of prenaldehyde, and the product selectivity can reach up to 99.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com