Three dimensional pattern moulding method and product thereof

A pattern forming and three-dimensional technology, which is applied in the field of three-dimensional pattern forming methods and its products, can solve the problems of quality differences, monotonous appearance, and difficulty in meeting the needs of mobile phone back covers, so as to achieve rapid prototyping and enhance industrial competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means of the present invention and the effects it can achieve more completely and clearly disclosed, the detailed description is as follows, please refer to the disclosed figures and figure numbers:

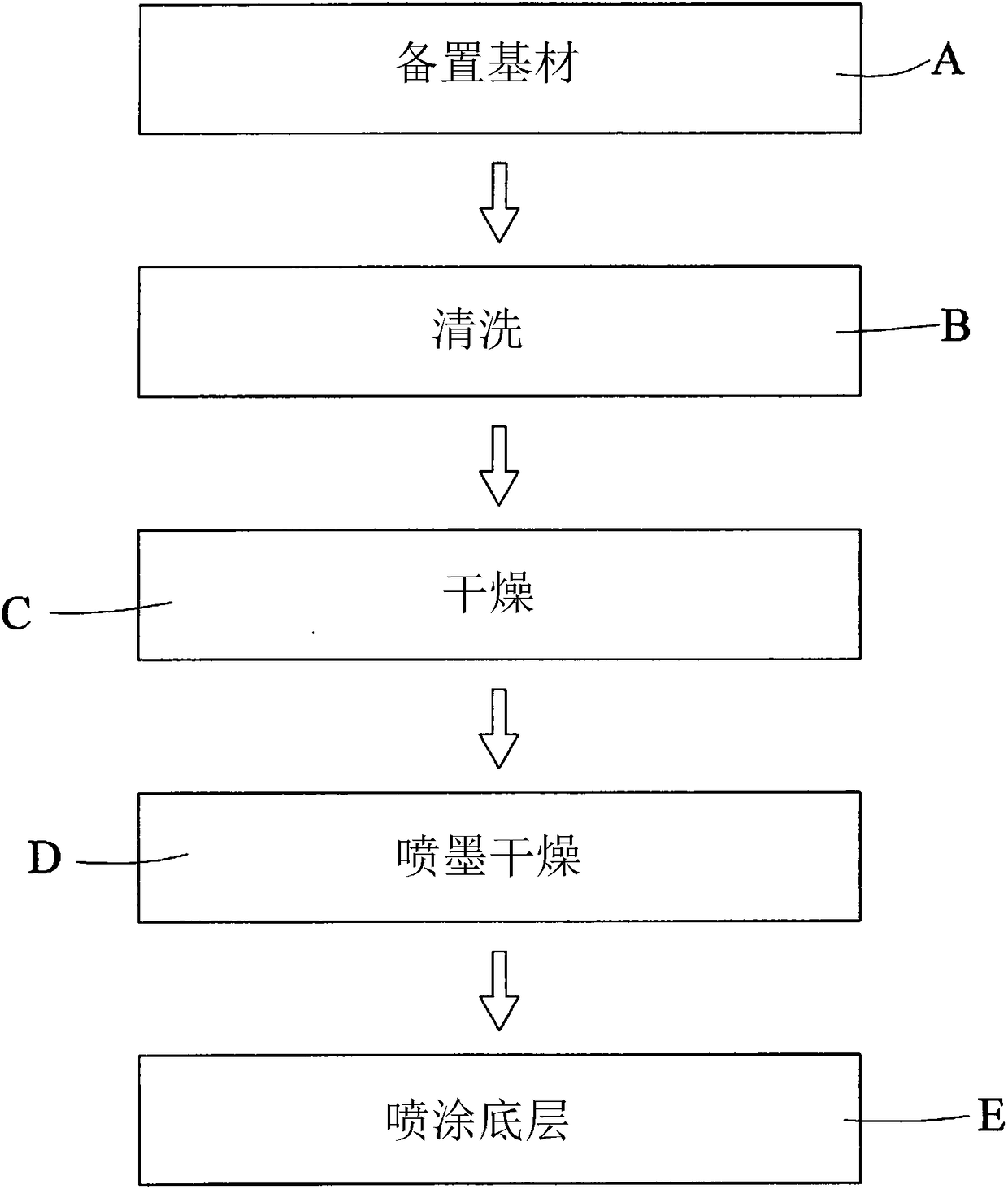

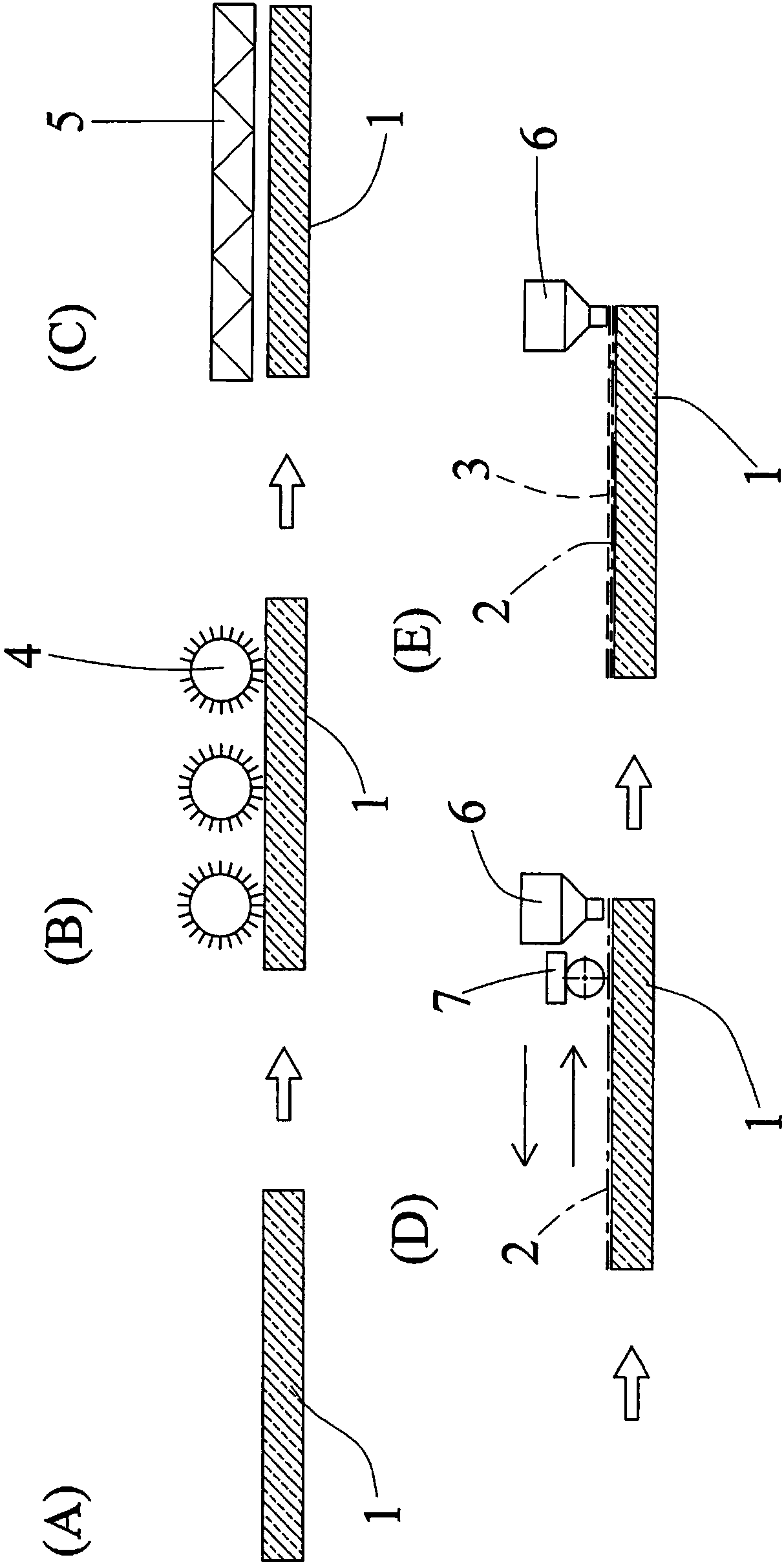

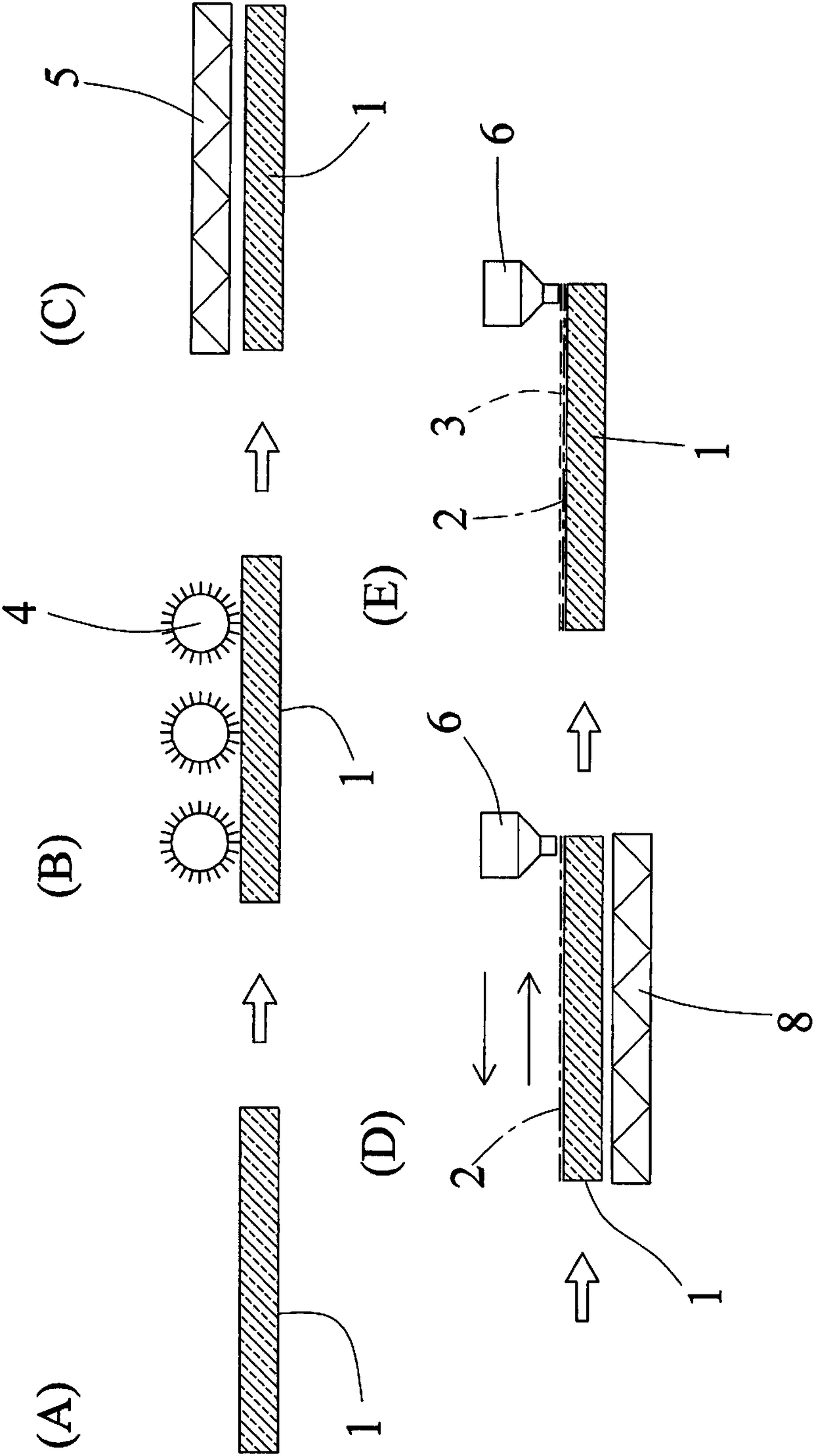

[0023] First, see figure 1 and figure 2 As shown, it is the three-dimensional pattern forming method of the present invention, and its implementation steps include:

[0024] A. Prepare substrate: prepare transparent substrate 1, the transparent substrate 1 is mainly glass products, such as: mobile phone back cover made of glass, etc.;

[0025] B. Cleaning: place the transparent base material 1 in automatic cleaning equipment, and make the rolling brush 4 of the automatic cleaning equipment remove the grease on the surface of the transparent base material 1 with a degreaser or cleaning agent, and then clean it with pure water clean;

[0026] C. Drying: place the cleaned transparent substrate 1 in a heating device 5 such as an oven to dry o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com