Powder stirring device with higher stirring uniformity

A stirring device and powder technology, which is applied to mixers with rotating stirring devices, mixer accessories, transportation and packaging, etc. It can solve the problems of inseparable powder coatings and powder coatings that cannot flow cleanly, so as to reduce waste and shorten the feeding time , the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

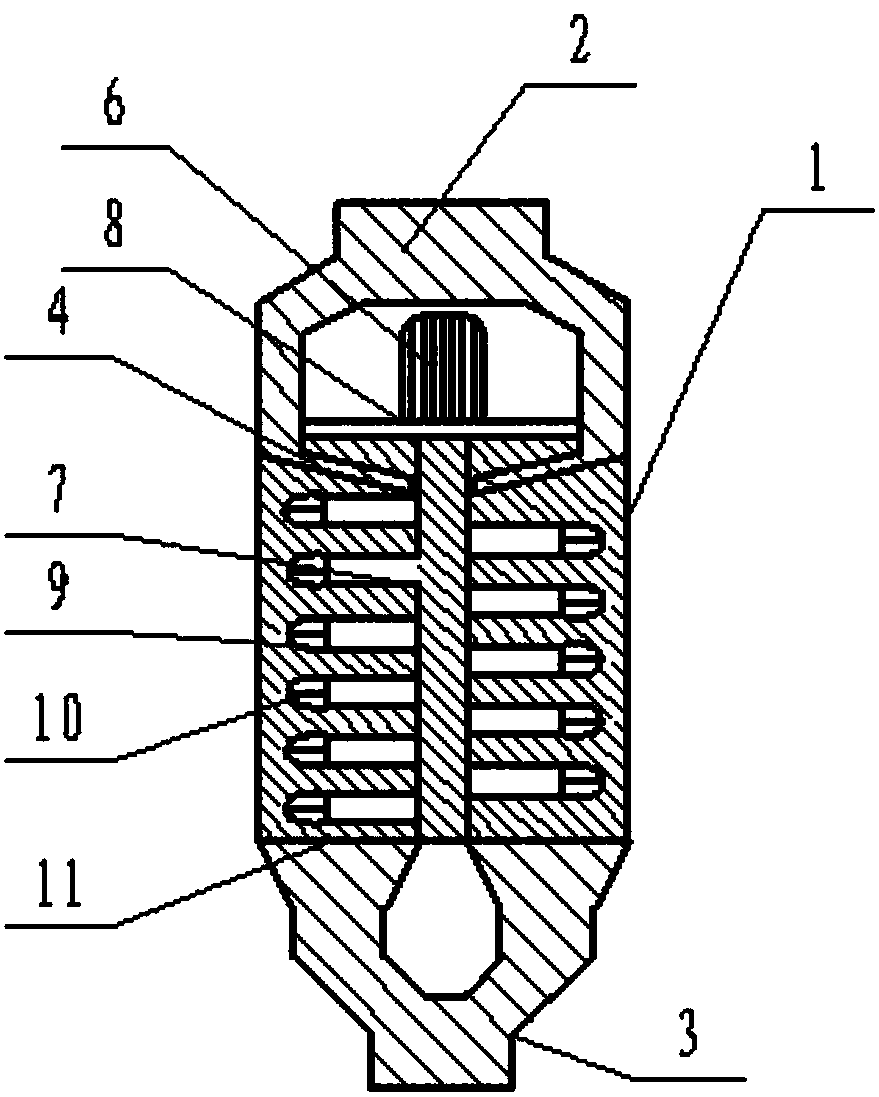

[0012] As shown in the accompanying drawings, the present invention will be further described: the present invention is a powder stirring device that stirs more uniformly, including a stirring device body 1, a material inlet 2, a material outlet 3, an inclined plate 4, a circular hole 5, and a motor 6 , rotating shaft 7, hair brush 8, stirring rod 9, stirring cage 10, material retaining valve 11, the top of the stirring device body 1 is provided with a material inlet 2, and the material inlet 2 is divided into two branches at the top of the stirring device body 1, Each branch is connected with an inclined plate 4 inside the stirring device body 1, the inclined plate 4 is provided with a round hole 5, the bottom of the stirring device body 1 is provided with a discharge port 3, and the discharge port 3 is connected to the stirring device body 1 Divided into two branches, each branch is inclined structure. The diameter of the brush 8 is smaller than the distance between the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com