Preparation of solid capsules comprising flavours

A seasoning and solid technology, applied in capsule delivery, microsphere preparation, microcapsule preparation, etc., can solve problems such as high energy cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

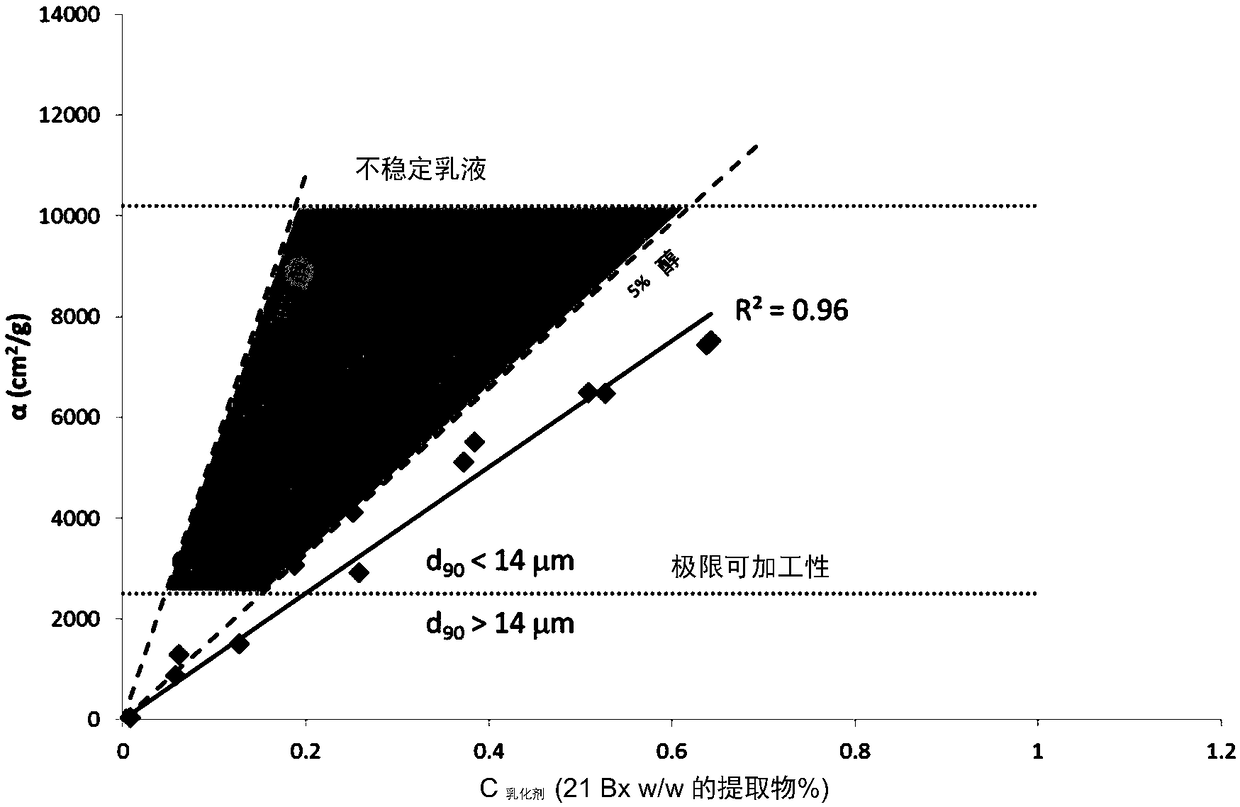

Image

Examples

Embodiment 1

[0088] According to the preparation of solid capsule of the present invention

[0089] Emulsion A was prepared by homogenizing the following ingredients:

[0090] Table 1 : Composition of Emulsion A

[0091] Element

share(%)

Contains natural extracts of saponins 1)

0.49

38.30

seasoning 3)

14.83

alcohol 4) (seasoning: alcohol = 90:10)

1.65

water

44.74

[0092] 1) Q-Naturale TM (Quillaba bark extract solution in water (21Brix), source: Ingredion Inc, NJ, USA)

[0093] 2) Mix 10DE maltodextrin and sucrose 50:50

[0094] 3) Limonene mimics orange flavoring

[0095] 4) Linalool as an alcohol used as part of a fragrance or seasoning

[0096] The polysaccharides (maltodextrin 10DE and sucrose) were incorporated into the water. Introducing Q-Naturale TM As a liquid solution (21% w / w dry). Add the orange flavored oil, with The solution was stirred with a mixer (Lightnin, Rocheste...

Embodiment 2

[0108] According to the preparation of solid capsule of the present invention

[0109] Emulsion B was prepared by homogenizing the following ingredients:

[0110] table 3 : Composition of Emulsion B

[0111] Element

share(%)

Contains natural extracts of saponins 1)

0.86

38.27

seasoning 3)

13.17

alcohol 4) (seasoning: alcohol = 80:20)

3.29

water

44.41

[0112] 1) Q-Naturale TM (Quillaba bark extract solution in water (21Brix), source: Ingredion Inc, NJ, USA)

[0113] 2) Mix 10DE maltodextrin and sucrose 50:50

[0114] 3) Limonene mimics orange flavoring

[0115] 4) Linalool as an alcohol used as part of a fragrance or seasoning

[0116] The polysaccharides (maltodextrin 10DE and sucrose) were incorporated into the water. Introducing Q-Naturale TM As a liquid solution (21% w / w dry). Add the orange flavored oil, with The solution was stirred with a mixer (Lightnin, Rocheste...

Embodiment 3

[0128] According to the preparation of solid capsule of the present invention

[0129] Emulsion C was prepared by homogenizing the following ingredients:

[0130] table 5 : Composition of Emulsion C

[0131] Element

share(%)

Contains natural extracts of saponins 1)

0.34

38.31

seasoning 3)

9.89

alcohol 4) (seasoning: alcohol = 60:40)

6.59

water

44.87

[0132] 5)Q-Naturale TM (Quillaba bark extract solution in water (21Brix), source: Ingredion Inc, NJ, USA)

[0133] 6) Mix 10DE maltodextrin and sucrose 50:50

[0134] 7) Limonene Mimics Orange Flavoring

[0135] 8) Linalool as an alcohol used as part of a fragrance or seasoning

[0136] The polysaccharides (maltodextrin 10DE and sucrose) were incorporated into the water. Introducing Q-Naturale TM As a liquid solution (21% w / w dry). Add the orange flavored oil, with The solution was stirred with a mixer (Lightnin, Rochester,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com