Device and method for rapidly separating and extracting micro-plastics in surface water

A technology of microplastics and surface layer, applied in measurement devices, analytical materials, sampling, etc., can solve the problems of inability to fully carry out microplastics environmental pollution investigation work, multi-manpower and material resources, and high costs, so as to reduce the probability of environmental pollution and reduce work. The effect of high volume and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

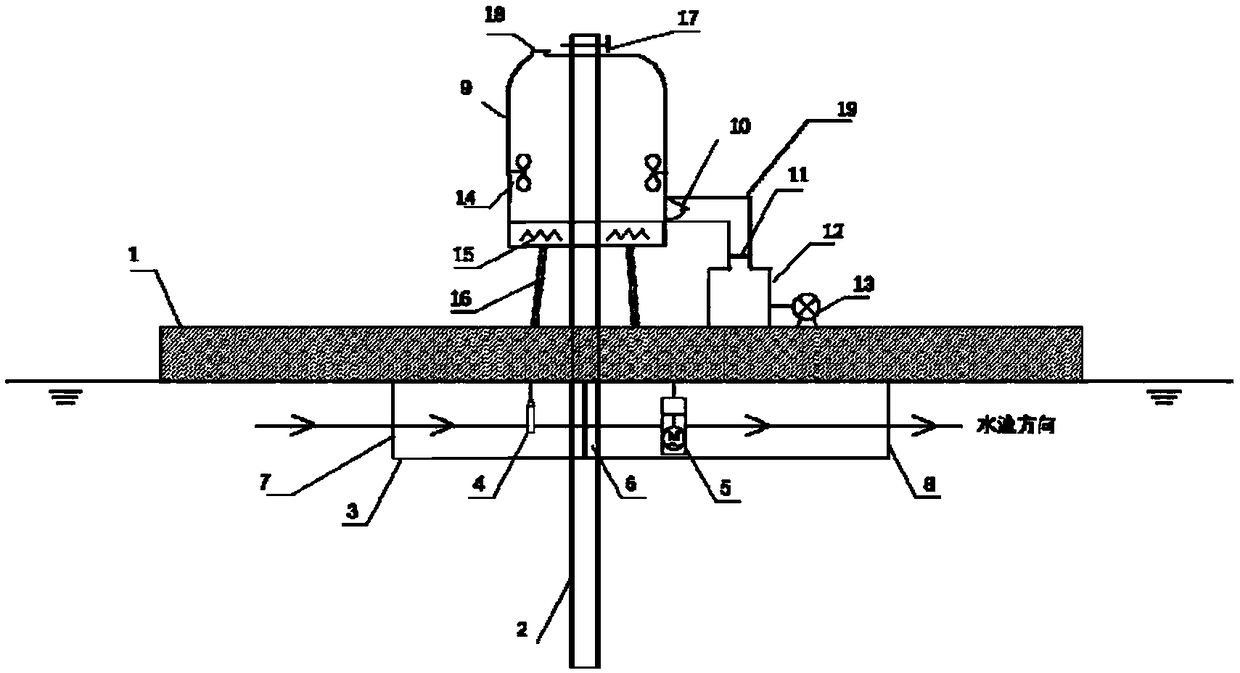

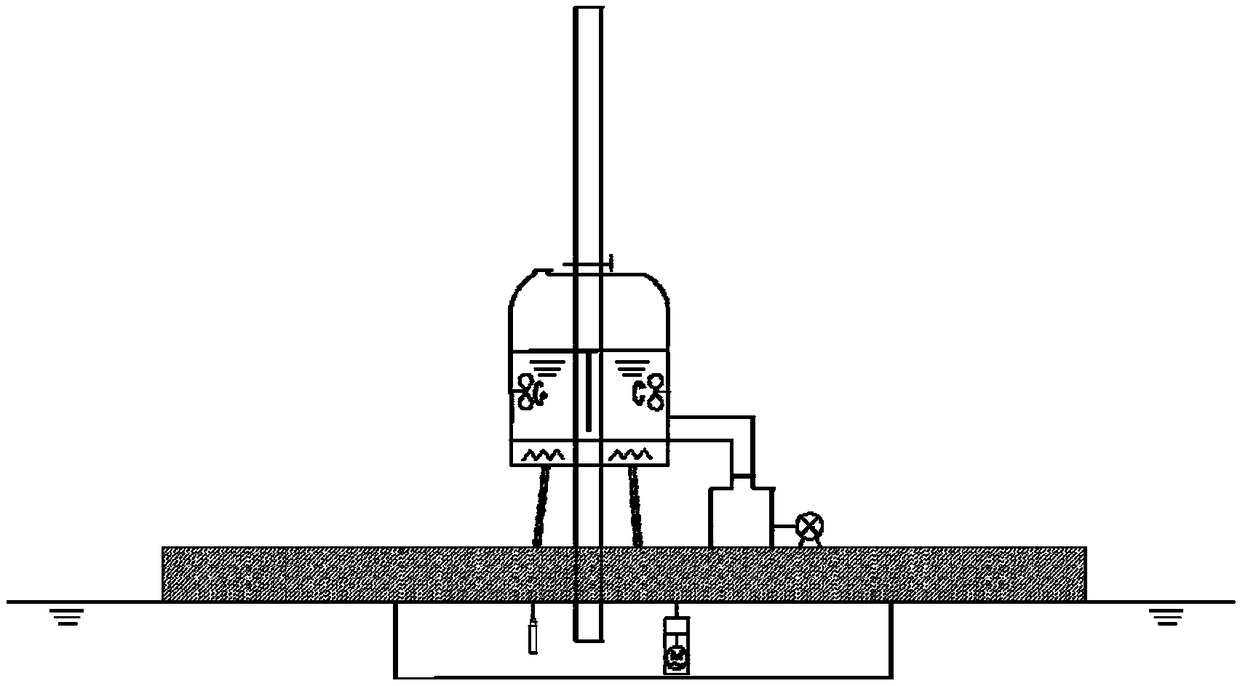

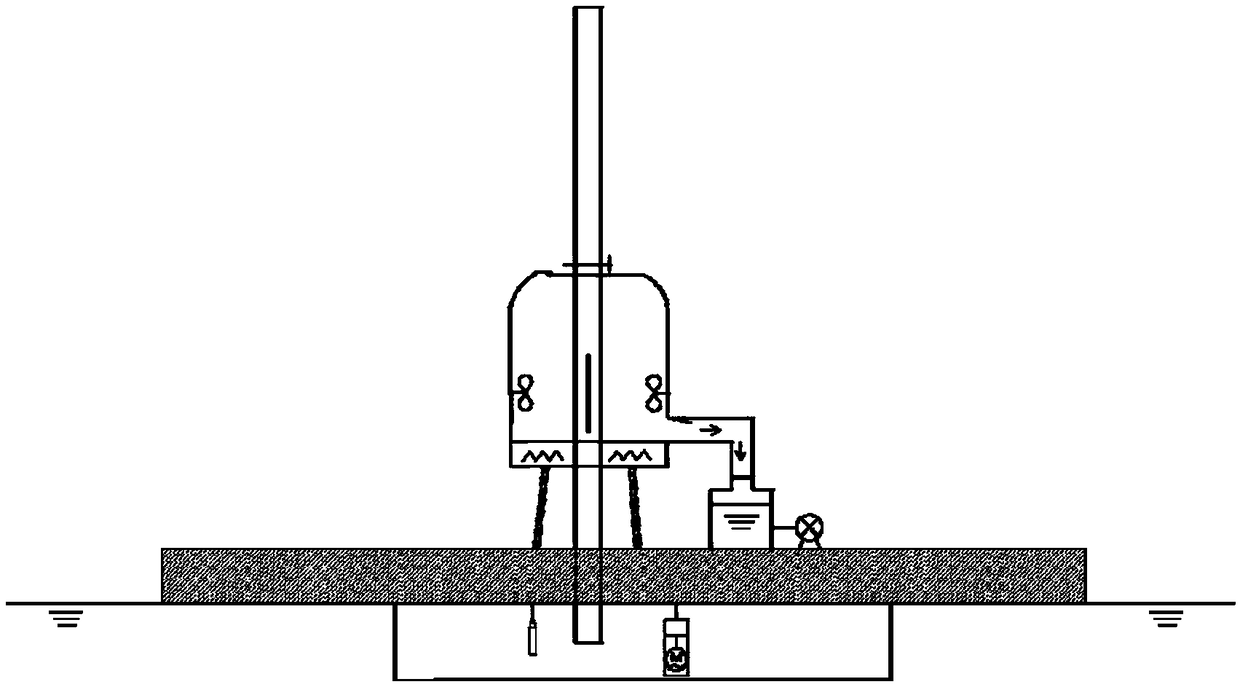

[0035] Such as figure 1 As shown, a device for quickly separating and extracting microplastics in surface water, including a floating platform 1, a lifting rod 2, a filter cartridge 3, a digestion tank 9, a waste liquid tank 12, a first filter membrane 6 and a second filter membrane 11 , wherein, the filter cartridge 3 is installed under the floating platform 1, and the water inlet and outlet of the filter cartridge 3 are respectively equipped with an inlet filter plate 7 and an outlet filter plate 8 with a pore size of 1 to 5 mm; the digestion tank 9 is installed on the floating platform 1 Above, the digestion tank 9 and the waste liquid tank 12 are connected through the drain pipe 19, and the digestion liquid partition 10 is cut off between the digestion tank 9 and the liquid drain pipe 19, and a second The filter membrane 11 and the waste liquid tank 12 are connected with a vacuum pump 13; the lifting rod 2 vertically passes through the filter cartridge 3, the floating plat...

Embodiment 2

[0040]A device for quickly separating and extracting surface water microplastics of the present invention was applied to the monitoring and research of water microplastics in a bay of Taihu Lake, and the monitoring was repeated three times at the same sampling point.

[0041] Fix the device at the sampling point, start the submersible pump 5, adjust the power of the submersible pump 5 according to the data of the flow meter 4, and stabilize the flow rate of the water body passing through the filter cartridge 3. The filtering conditions of the three monitorings are: average flow rate 5L / min, continuous filtration for 10min; average flow rate 5L / min, continuous filtration for 5min; average flow rate 10L / min, continuous filtration for 10min. Then close the submersible pump 5, untie the lifting rod fixing ring 17, promote the lifting rod 2 positions, make the first filter membrane 6 enter the digestion tank 9; pour 30% H in the digestion tank 9 from the liquid inlet 18 2 o 2 and ...

Embodiment 3

[0046] A device for rapidly separating and extracting surface water microplastics of the present invention is applied in a standard addition experiment in a laboratory to verify the accuracy of the system.

[0047] Set up a fish tank with a volume of 500L in the laboratory and add 300L of pure water without plastic. Add polyethylene microplastic standard products with particle sizes ranging from 42 to 46 μm to pure water to make the abundance of microplastics in the water body reach 20 items / L. Then the device in the present invention is fixed in the fish tank, start the submersible pump 5, adjust the power of the submersible pump 5 according to the reading of the flowmeter 4, make the water flow rate by the filter cartridge 3 stabilize at 3L / min, and continue to filter for 2h; then Close the submersible pump 5, untie the lifting rod fixing ring 17, lift the lifting rod 2 position, and make the first filter membrane 6 (cellulose acetate microporous filter membrane with a pore ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com