Friable rock stratum sample-collection drill pipe structure

A sample collection and drill pipe technology, which is applied in the field of geological exploration, can solve problems such as low core recovery rate, influence on accuracy, and inability to analyze and detect, and achieve the effects of improving solidification efficiency, avoiding separation and fragmentation, and improving sampling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

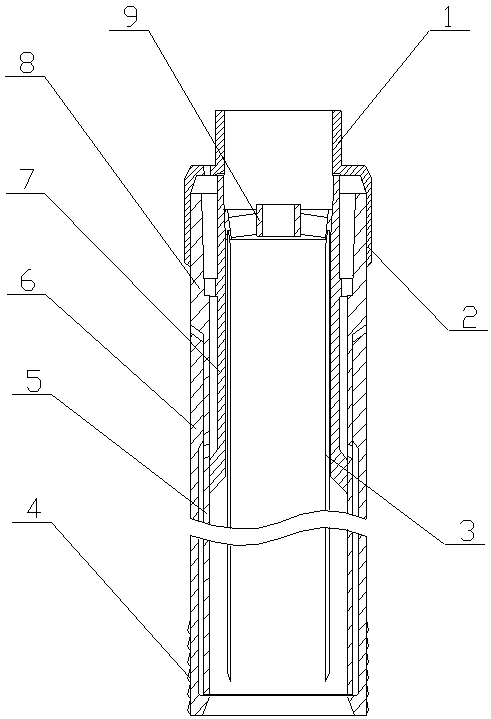

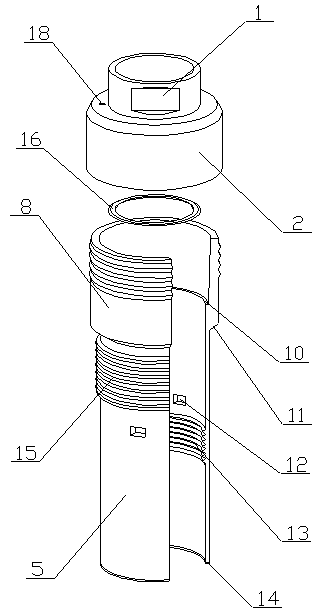

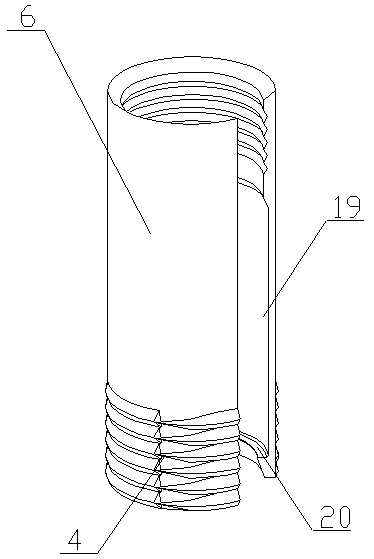

[0020] The structure of the drill pipe for sample collection of fragile rock formations of the present invention is realized in this way, consisting of the drill pipe chuck (1), connecting sleeve (2), sampling pipe (3), drill pipe edge (4), lower partition pipe (5), Outer drill bushing (6), inner bushing (7), upper fixing sleeve (8), sampling chuck (9), inner limiter (10), outer limiter (11), communication groove (12), Internal thread (13), gasket (14), external thread (15), sealing ring (16), tapered communication hole (18), inner annular groove (19), inner supporting ring (20), outer annular groove ( 21), the limit ring (22) and the diversion groove (23), the inner support ring (20) is placed on the inner wall of one end of the outer drill sleeve (6), and the inner diameter of the inner support ring (20) gradually increases from bottom to top reduced, multiple groups of drill pipe edges (4) are equidistantly arranged on the outer wall of the outer drill sleeve (6), and the d...

Embodiment 2

[0023] The difference between this embodiment and Embodiment 1 is that: the outer wall of the inner bushing (7) is provided with a deflector (24), which is located in the lower chamber, and the deflector (24) is a spiral plate. The deflector (24) is provided with a plurality of through holes (17), which are distributed in a spiral. When in use, when the coolant is injected, the coolant flowing into the lower chamber through the guide groove (23) will flow in a spiral along the deflector (24), and then the coolant will be distributed in the lower chamber more uniform;

[0024] The inner diameter of the inner support ring (20) is designed to gradually decrease from bottom to top, so that the inner surface of the inner support ring (20) is inclined, and then the soil sample gradually enters the lower dividing tube (5) along the inclined surface. to sample;

[0025] A sealing gasket (14) is placed on the other end surface of the lower separating pipe (5), and it is designed to fit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com