D-tryptophan methyl ester hydrochloride drying device based on lifting and discharging technology

A technology of tryptophan methyl ester and drying device, which is applied in the directions of drying gas arrangement, drying solid materials, drying chamber/container, etc., can solve problems such as inconvenience, chemical liquid corrosion, drying box corrosion, etc., to ensure safety and protect safety. , the effect of reducing residual

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

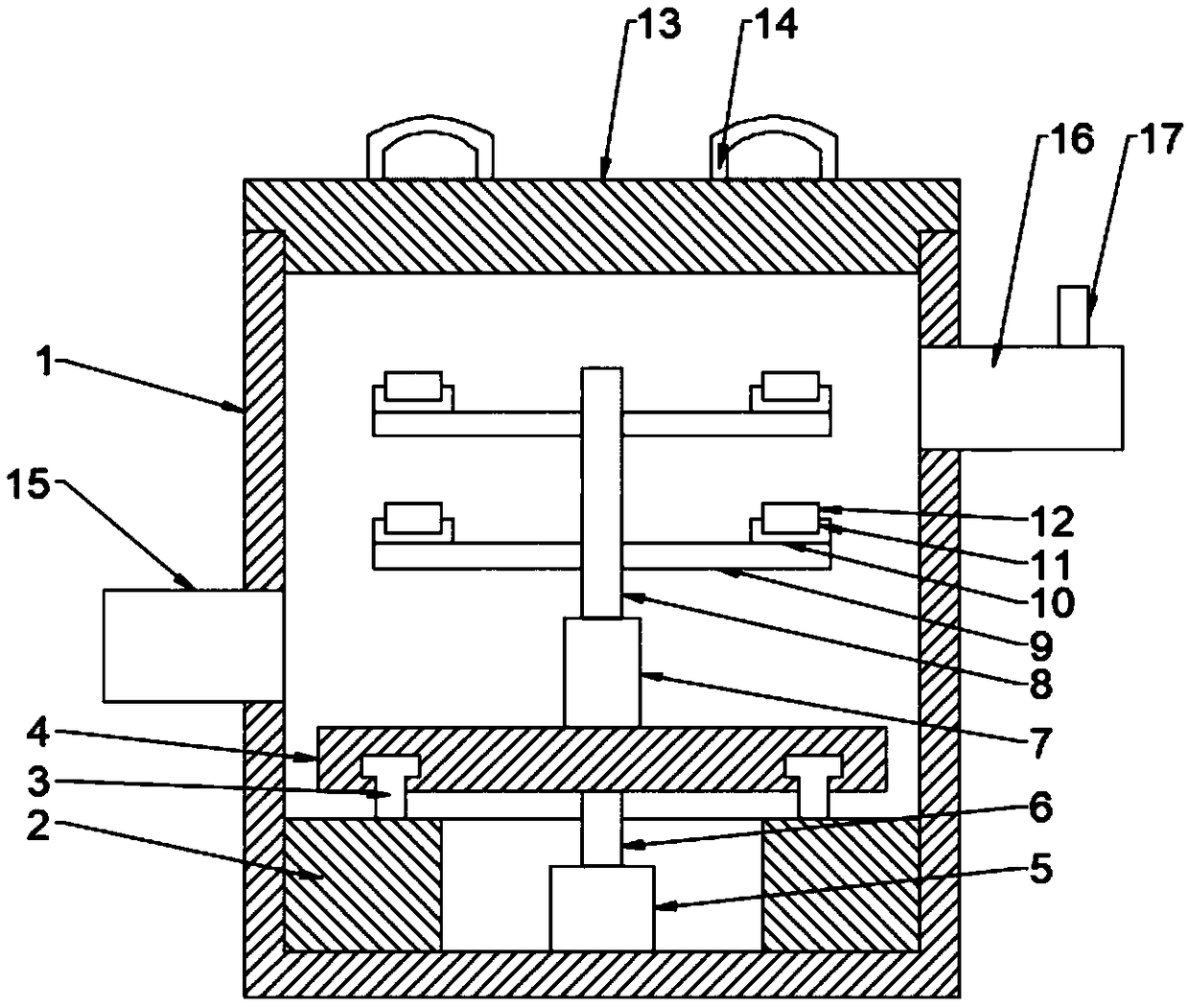

[0024] see Figure 1~3 , a D-tryptophan methyl ester hydrochloride drying device based on lifting and unloading technology, the box 1 is a cylindrical structure with an open top, and the edge of the bottom wall of the inner cavity of the box 1 is provided with a support platform 2 , the support platform 2 is a ring structure, the axis of the support platform 2 coincides with the axis of the box body 1, the top of the support platform 2 is provided with a guide rail 3, the guide rail 3 is a ring structure, and the single side of the guide rail 3 is horizontal The cross-section is a T-shaped structure, and the top of the guide rail 3 is provided with a base 4, which is rotationally connected between the guide rail 3 and the base 4, and the base 4 can rotate along the guide rail 3; There is an electric telescopic device 7, the outer circular surface of the telescopic rod 8 on the electric telescopic device 7 is evenly provided with a number of support rods 9, and the top surface ...

Embodiment 2

[0027] This embodiment is a further elaboration on the basis of Embodiment 1. A motor 5 is provided in the center of the bottom wall of the inner cavity of the box body 1. The motor shaft on the motor 5 is fixedly connected to the rotating shaft 6. The axis of the rotating shaft 6 It coincides with the axis of the box body 1, and the other end of the rotating shaft 6 is fixedly connected to the bottom end of the base 4, and the starting motor 5 drives the rotating shaft 6, thereby driving the base 4 to rotate on the guide rail 3, thereby driving the seat plate 10 to rotate, Thereby improving the drying efficiency and drying quality of D-tryptophan methyl ester hydrochloride.

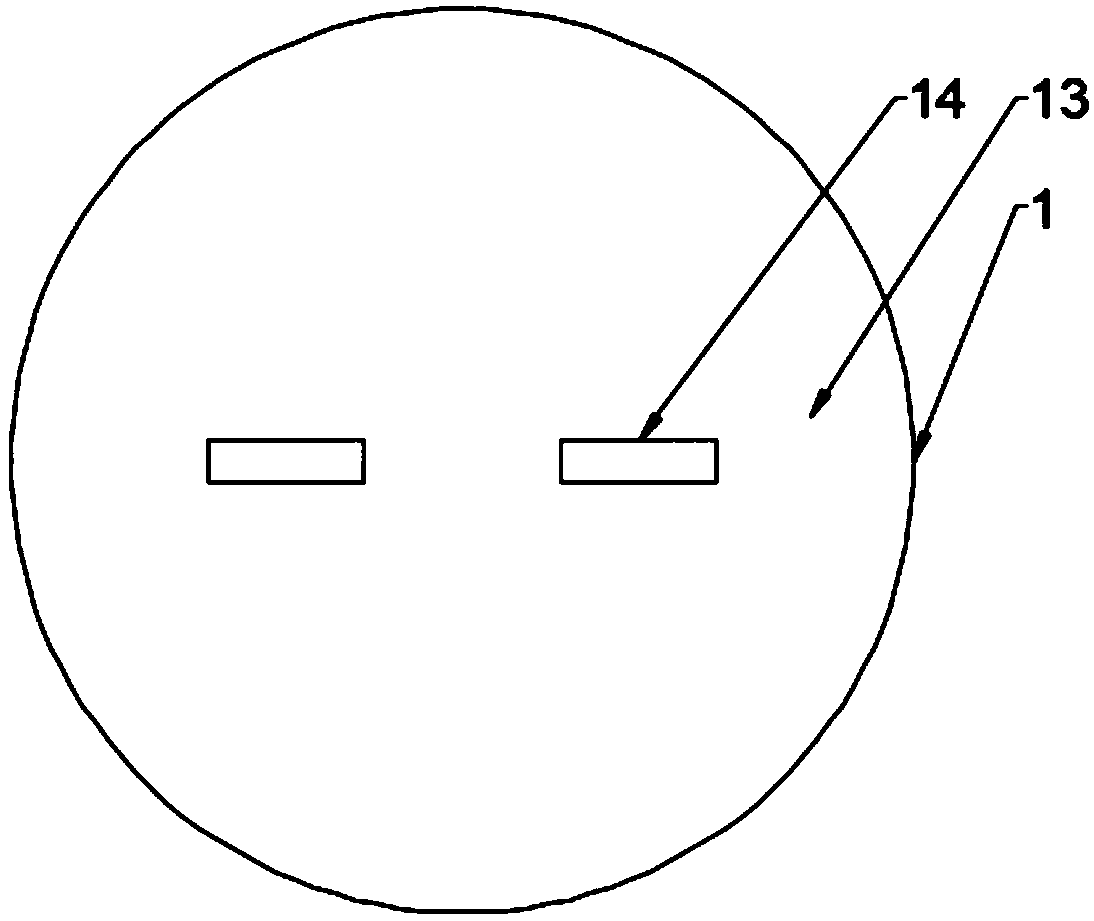

[0028] The top opening of the box body 1 is provided with a sealing cover 13, and the left and right sides of the top surface of the sealing cover 13 are symmetrically provided with handles 14. The handle 14 is a U-shaped structure, and the sealing cover 13 is opened to start the electric telescopic devic...

Embodiment 3

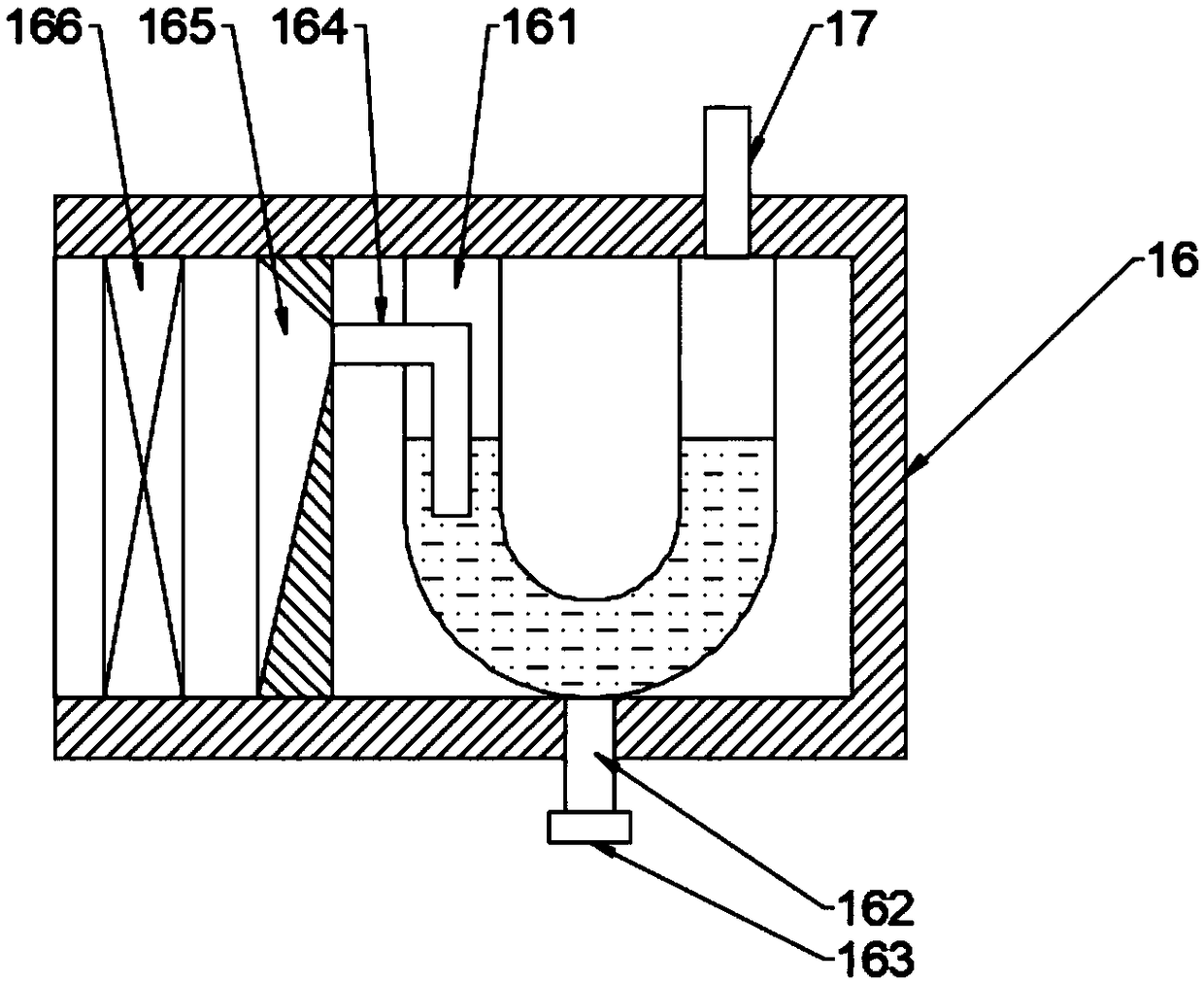

[0030] This embodiment is a further elaboration on the basis of Embodiment 1. The exhaust tube 16 is a cylindrical structure with an open left end, and the inner cavity of the exhaust tube 16 is provided with exhaust fans 166 in sequence from left to right. , diversion bucket 165 and filter tube 161, the filter tube 161 is a U-shaped structure, one side end of the filter tube 161 is connected to the air outlet pipe 17, and the top of the air outlet pipe 17 runs through the top wall of the exhaust tube 16 The bottom end of the filter pipe 161 is connected to the water exchange pipe 162, and the other end of the water exchange pipe 162 passes through the bottom wall of the exhaust cylinder 16 and is sleeved with a sealing plug 163. The filter pipe 161 The other end of the air pipe 164 is connected through the air pipe 164, and the other end of the air pipe 164 is connected with the diversion bucket 165, and the exhaust fan 166 is activated to draw the gas in the box 1 into the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com