Bidirectional draining pump brake and control system

A two-way drainage and water intake control technology, applied in pump control, pumps, pump devices, etc., can solve the problems of low pump efficiency, large footprint, and high cost, and achieve high pump efficiency, small footprint, and low cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

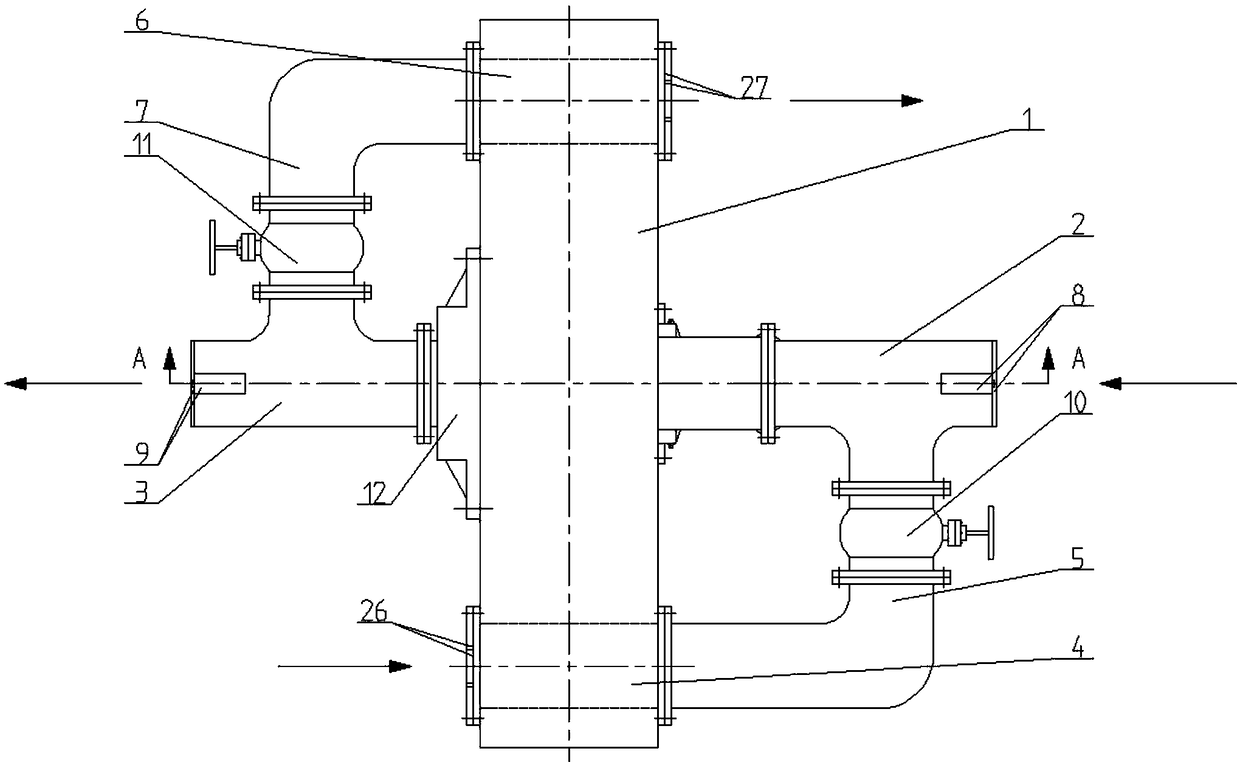

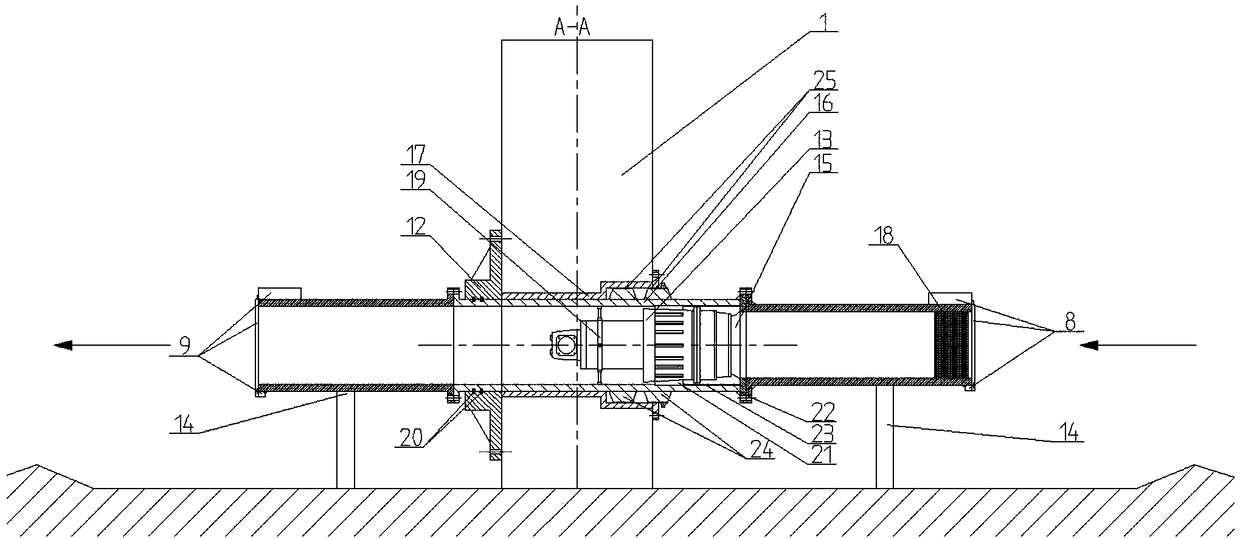

[0056] figure 1 and 2 Shown is an embodiment of the two-way drainage pump gate of the present invention. The two-way drainage pump gate includes a gate 1, a sleeve 17, a pump barrel 16, a horizontal axial flow pump 13, a water inlet pipe 4, and a water outlet pipe 6. , water inlet control valve 10 and water outlet control valve 11;

[0057] The sleeve 17 is installed in the gate 1 , preferably, the sleeve 17 is installed at the inner center lower position of the gate 1 through a flange connection.

[0058] The pump barrel 16 is installed in the sleeve 17;

[0059] The horizontal axial flow pump 13 is installed in the pump barrel 16;

[0060]The water inlet pipe 4 is installed in the gate 1, one end of the water inlet pipe 4 is provided with a second water inlet flap 26, and the other end is connected to the water inlet of the horizontal axial flow pump 13 through a pipeline;

[0061] The water outlet pipe 6 is installed in the gate 1, one end of the water outlet pipe 6 is ...

Embodiment 2

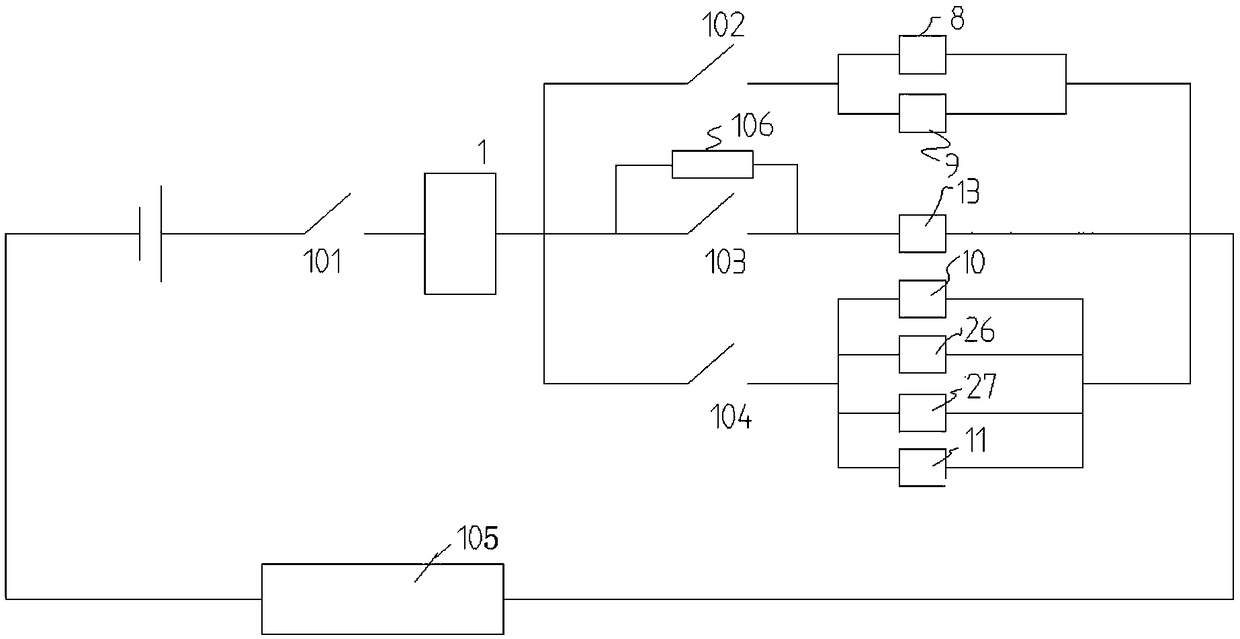

[0084] A two-way drainage pump gate control system, comprising the two-way drainage pump gate and controller in Embodiment 1;

[0085] The controller is respectively connected with the gate (1), the horizontal axial flow pump (13), the liquid level sensor (106), the first water inlet flapper door (8), the first water outlet flapper door (9), and the second inlet flapper door (9). The water flapping door (26), the second water outlet flapping door (27), the water inlet control valve (10) and the water outlet control valve (11) are connected.

[0086] When the water flow submerges the impeller of the horizontal axial flow pump 13 , the liquid level sensor 106 detects the liquid level signal and transmits it to the controller, and the controller controls the horizontal axial flow pump 13 to work.

[0087] When the right side enters water and the left side exits: the controller controls the gate 1 to close, opens the first water inlet flap gate 8 and the first water outlet flap ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com