Diversion type oil-water separator

A technology of oil-water separator and guide box, which is applied in separation method, liquid separation, grease/oily substance/float removal device, etc., can solve the problems of water level influence, high civil construction cost and high civil construction requirements, and achieves a simple structure. , The effect of uniform oil removal and good water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

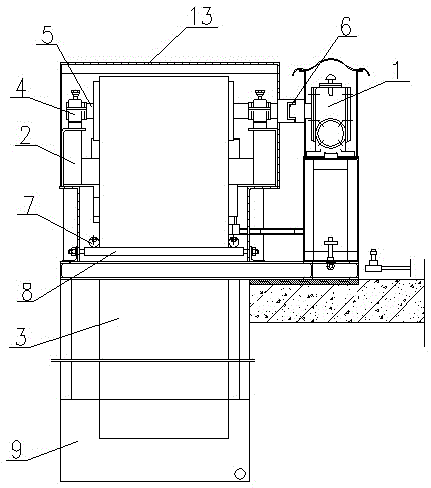

[0014] A diversion type oil-water separator, including a transmission device 1, a frame 2, and an oil removal belt 3, a transmission shaft 5 is fixedly installed on the frame 2 through two bearings 4, and the transmission shaft 5 is connected to the transmission device through a coupling 6 1 connection, the degreasing belt 3 is set on the drive shaft 5, the two sides of the degreasing belt 3 are provided with a guide wheel shaft 7 located at the lower end of the frame 2, and the front end of the degreasing belt 3 is provided with a guide shaft cylinder 8 located at the lower end of the frame 2, the machine The bottom of the frame 2 is provided with a diversion box 9 located under the liquid surface, the lower end of the degreasing belt 3 is immersed in the diversion box 9, and the frame 2 is provided with a self-priming diversion pump 10 connected to the diversion box 9 through a drainage tube 11. A return pipe 12 is also provided on the self-priming diversion pump 10 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com