Tail gas dedusting and purifying device

A technology for purification device and exhaust gas dust removal, which is applied to exhaust devices, mufflers, exhaust gas treatment, etc. The effect of solid and particle size range is wide and dust removal efficiency is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings, so as to make the technical solution of the present invention easier to understand and grasp.

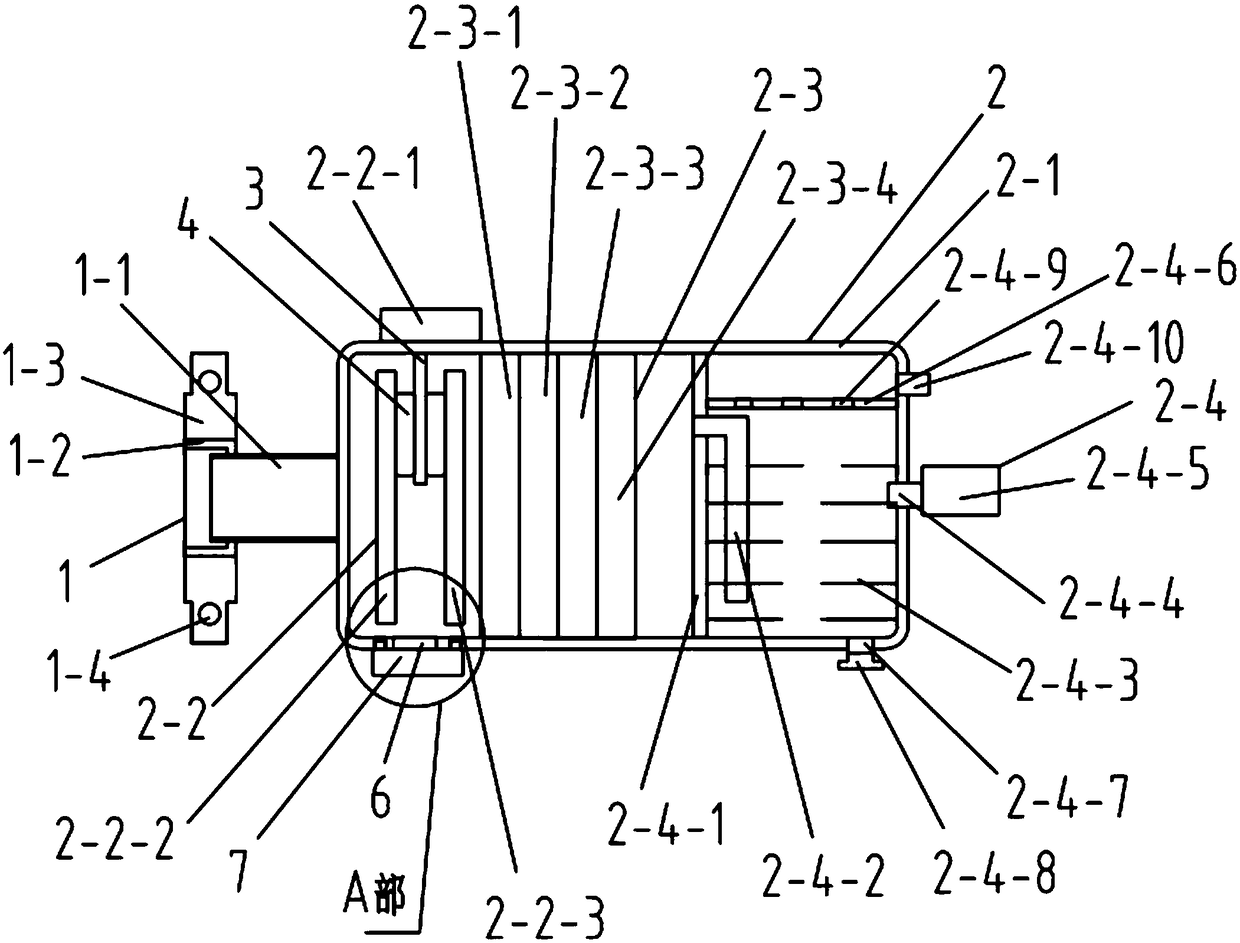

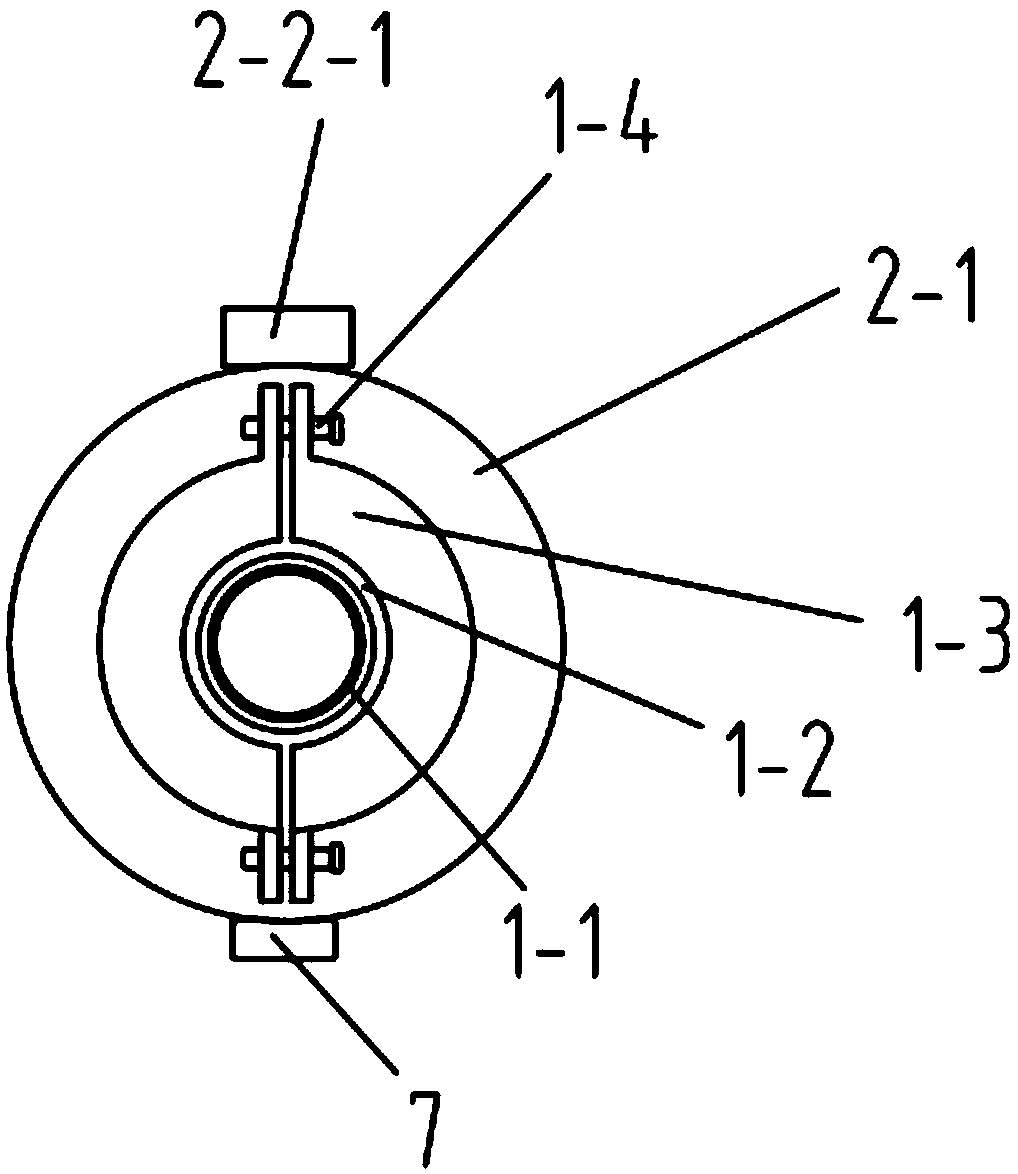

[0020] Such as Figure 1-3 As shown, an exhaust dust removal and purification device includes a connection assembly 1 and a purification device body 2, the purification device body 2 is fixedly connected to the connection assembly 1, and the connection assembly 1 includes a connection pipe 1-1 and a sealing ring 1-2 , the connecting sleeve 1-3 and the adjusting bolt 1-4, the adjusting bolt 1-4 is threadedly connected with the connecting sleeve 1-3, the connecting sleeve 1-3 is sleeved on the sealing ring 1-2, and the sealing ring 1-2 is socketed on the connecting pipe 1-1, and the connecting pipe 1-1 is fixedly connected with the purification device body 2, and the purification device body 2 includes a housing 2-1, a high-voltage electros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com