Oil well pumping unit directly driven by frameless combined type permanent magnet synchronous motor

A permanent magnet synchronous motor and combined technology, which is applied in the field of oil well pumping units, can solve the problems of large impact of the pipe and rod system, large cost input, low work efficiency, etc., and achieves low energy loss, reduced equipment weight, and fast response speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

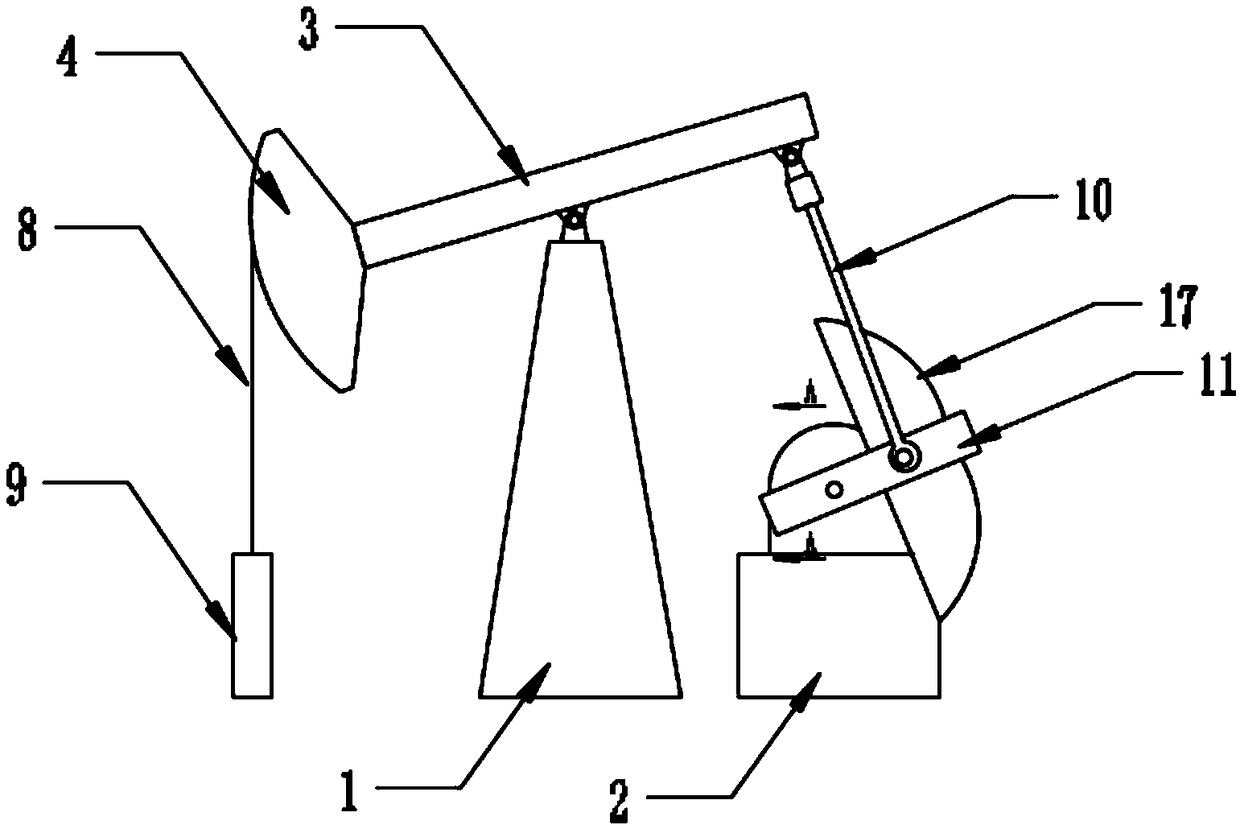

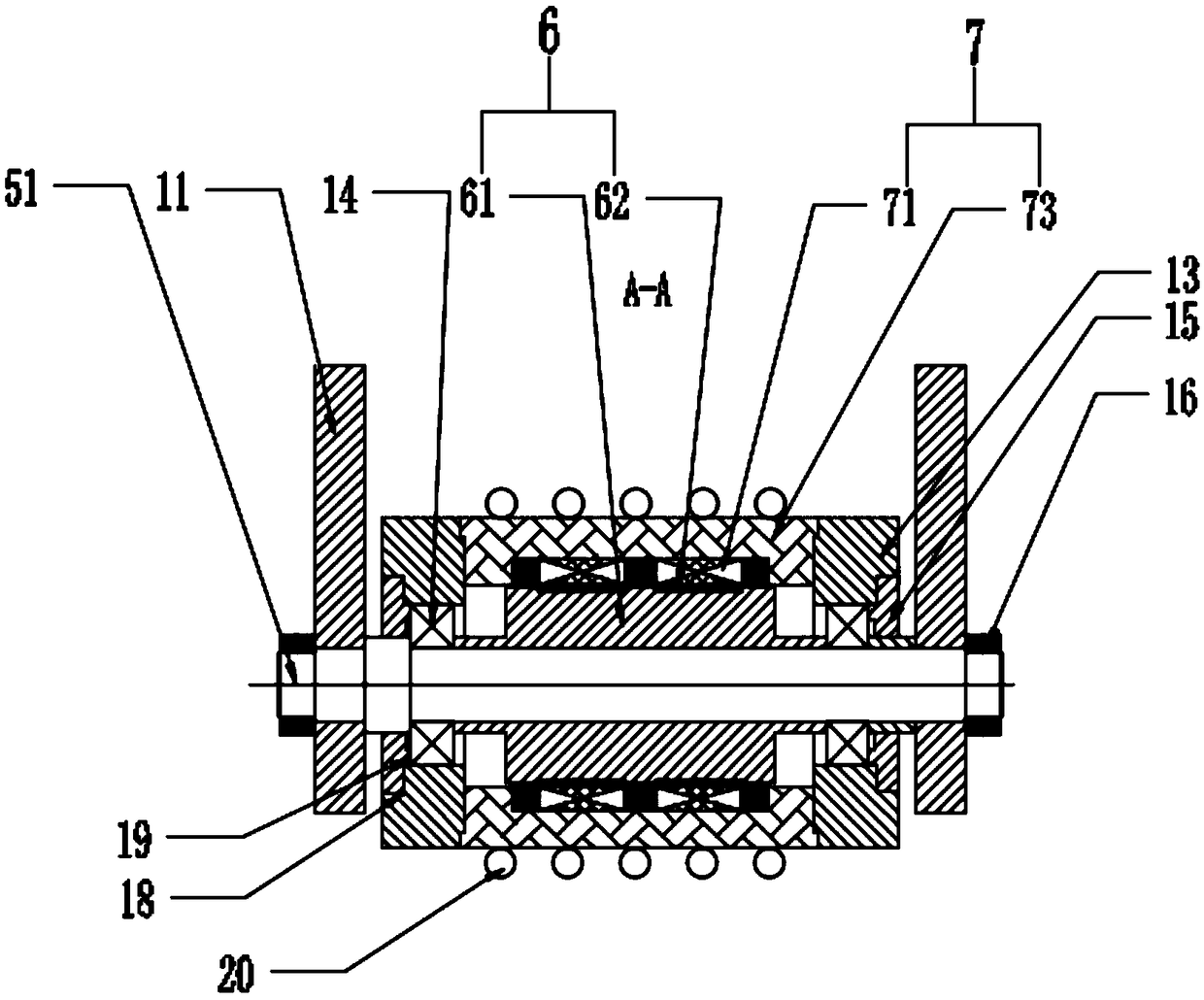

[0028] A frameless combined permanent magnet synchronous motor direct-driven oil well pumping unit described in this embodiment, combined with Figure 1 ~ Figure 4 For illustration, it includes a bracket 1 and a base 2 arranged on the ground, the upper part of the bracket 1 is hinged with the middle part of the beam 3, the front end of the beam 3 is fixed with a donkey head 4, and the donkey head 4 is connected by a wire rope 8 with a suspension rope 9, the lower end surface of the rear end of the beam 3 is hinged with the upper end of the connecting rod 10, and the lower end of the connecting rod 10 is hinged with the driving arm 11, and the driving arm 11 is driven by the frameless combined permanent magnet synchronous motor 5 arranged in the base 2. Direct drive, the driving arm 11 is provided with a counterweight 17; the frameless combined permanent magnet synchronous motor 5 includes a main shaft 51, a stator assembly 7 and a rotor assembly 6, and the driving arm 11 is fix...

Embodiment 2

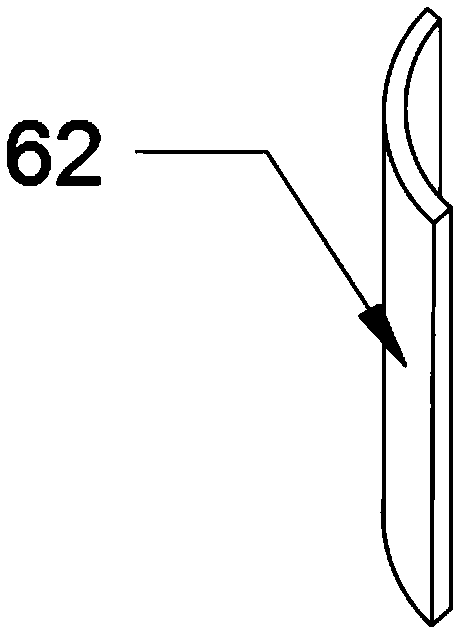

[0033]A frameless combined permanent magnet synchronous motor direct-driven oil well pumping unit described in this embodiment is basically the same as Embodiment 1, and the difference will be combined Figure 5 ~ Figure 7 To illustrate, the frameless combined permanent magnet synchronous motor 5 includes a main shaft 51, a stator assembly 7 and a rotor assembly 6, the driving arm 11 is fixedly installed on both ends of the main shaft 51 through nuts 16, the stator assembly 7 is fixedly installed in the base 2 and The rotating magnetic field is provided for the rotor assembly 6; the stator assembly 7 is composed of 6 stator units in a fan-shaped block structure, and the stator unit includes the second stator core 72 and the stator winding wound on the second stator core 72, the stator iron The second core 72 is an integrally formed ring-shaped cylindrical disc structure; the rotor assembly 6 with permanent magnet properties is fixedly installed on the main shaft 51 .

[0034] ...

Embodiment 3

[0037] A frameless combined permanent magnet synchronous motor direct-driven oil well pumping unit described in this embodiment is basically the same as Embodiment 1, and the difference will be combined Figure 8 To illustrate, the frameless combined permanent magnet synchronous motor 5 includes a main shaft 51, a stator assembly 7 and a rotor assembly 6, the driving arm 11 is fixedly installed on both ends of the main shaft 51 through nuts 16, the stator assembly 7 is fixedly installed in the base 2 and The rotating magnetic field is provided for the rotor assembly 6; the stator assembly 7 is composed of at least two stator units in a fan-shaped block structure, and the stator unit includes a stator core 71, a stator core 2 72 and a stator core 71 wound on the stator core 1. 1. The stator winding on the stator core two 72, the stator core one 71 is an integrally formed annular columnar structure; the stator core one 71 is an integrally formed annular columnar structure, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com