Roller type wedge transverse rolling machine directly driven by frameless permanent magnet synchronous motor

The technology of permanent magnet synchronous motor and cross wedge rolling mill is applied in the driving device, magnetic circuit, electromechanical device and other directions of metal rolling mill, which can solve the problems of large power loss, inconvenience in precise processing of rolling parts, low transmission accuracy, etc. Achieve the effect of reducing manufacturing cost, fast response speed and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

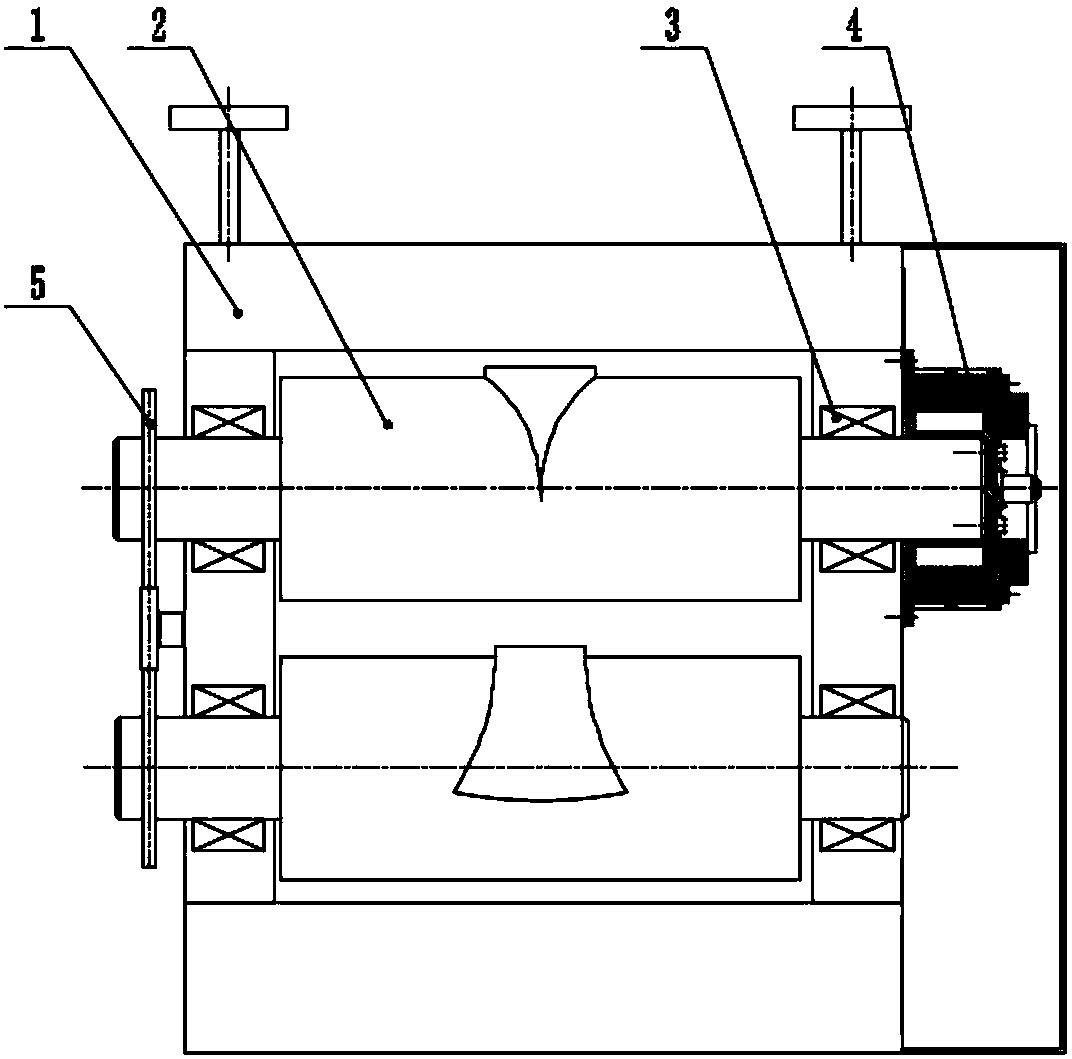

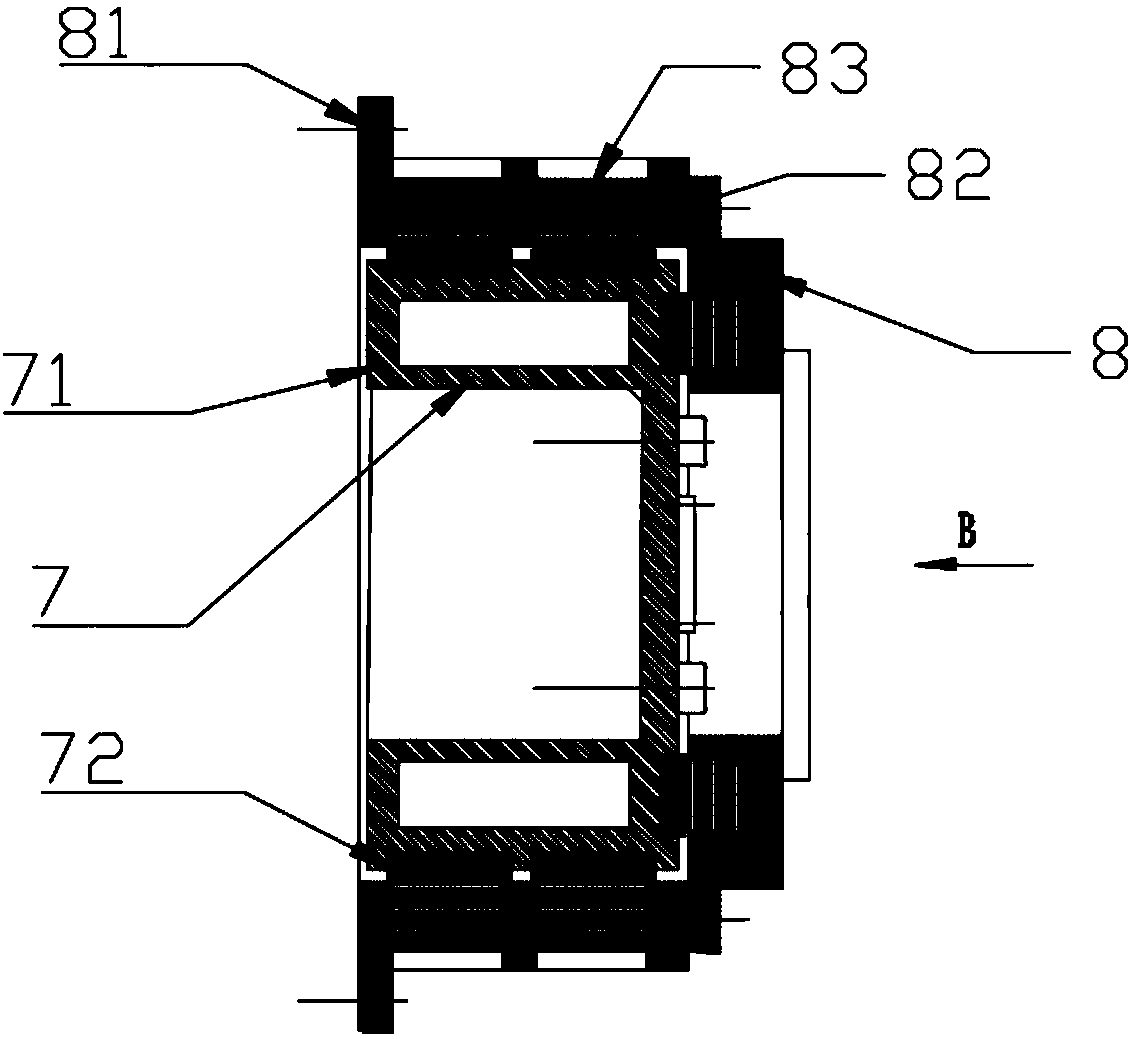

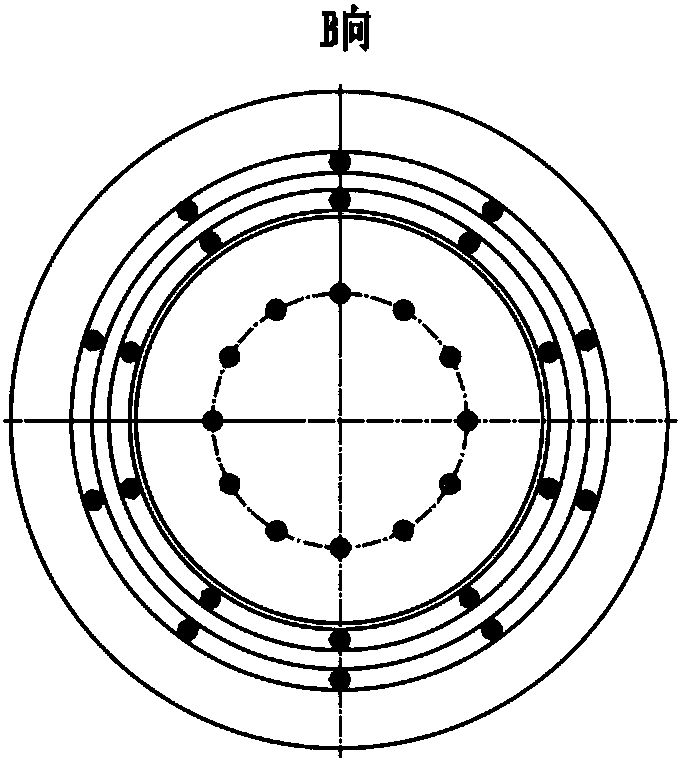

[0038] Such as Figure 1-5 As shown, this embodiment provides a frameless permanent magnet synchronous motor direct-driven roller cross wedge rolling mill, which includes a working rolling mill and a driving motor for driving the working rolling mill, and the working rolling mill includes a rolling mill Frame 1, two rolls 2 and support bearings 3 for supporting the rolls 2; the input end of the rolls 2 is directly driven by the drive motor; each of the rolls 2 and the rolling mill stand 1 There are support bearings 3 between them; the drive motor is a frameless permanent magnet synchronous motor 4, including a rotor assembly 7 and a stator assembly 8; wherein, the stator assembly 8 is opposite to the rotor assembly 7, and the stator assembly 8 A rotating magnetic field is provided to drive the rotor assembly 7 to rotate; the stator assembly 8 is fixedly connected to the rolling mill frame 1, and the rotor assembly 7 is fixedly connected to one of the rolls 2; the stator assemb...

Embodiment 2

[0042] Such as Image 6 As shown, the preferred embodiment of the present invention is to provide a frameless permanent magnet synchronous motor direct-driven roller type cross wedge rolling mill. The difference is that the cross wedge rolling mill in this embodiment is driven by two machines, and the number of the frameless permanent magnet synchronous motors 4 is the same as the number of the rolls 2; each of the frameless permanent magnet synchronous The motors 4 are fixedly connected to the input ends of the rolls 2 . Wherein, the cross wedge rolling mill includes two rolls 2, each of which is connected with a frameless permanent magnet synchronous motor 4 at the input end. The double motors work together to ensure the precise forming of the workpiece during rolling.

Embodiment 3

[0044] Such as Figure 7-9 As shown, the preferred embodiment of the present invention is to provide a frameless permanent magnet synchronous motor direct-driven roller type cross wedge rolling mill. The structure and working principle of this embodiment are similar to those of embodiment 1 or 2. The difference between 1 and 2 is that there is an air gap 6 between the stator base and the rotor base in this embodiment, and the two ends of the air gap 6 are respectively provided with at least two layers of seals arranged in parallel. Ring 61; the outer ring and the inner ring of the sealing ring 61 have a hook-shaped structure 62, and elastic balls 63 distributed in a ring are embedded in the connection between the hook-shaped structure 62 and the body of the sealing ring 61; The free ends of the hook structures 62 are located in the spaces formed by the plurality of sealing rings 61 , and the hook structures 62 are alternately in free contact with the stator base and the rotor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com