Composite crusher directly driven by permanent magnet synchronous motor

A technology of permanent magnet synchronous motor and compound crusher, which is applied in the direction of electrical components, electromechanical devices, grain processing, etc. It can solve the problems that the impact plate of the crusher is easy to be worn, the manufacturing cost is increased, and the installation is inconvenient, etc., and the drive can be simplified The method and structure, the effect of reducing the volume and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

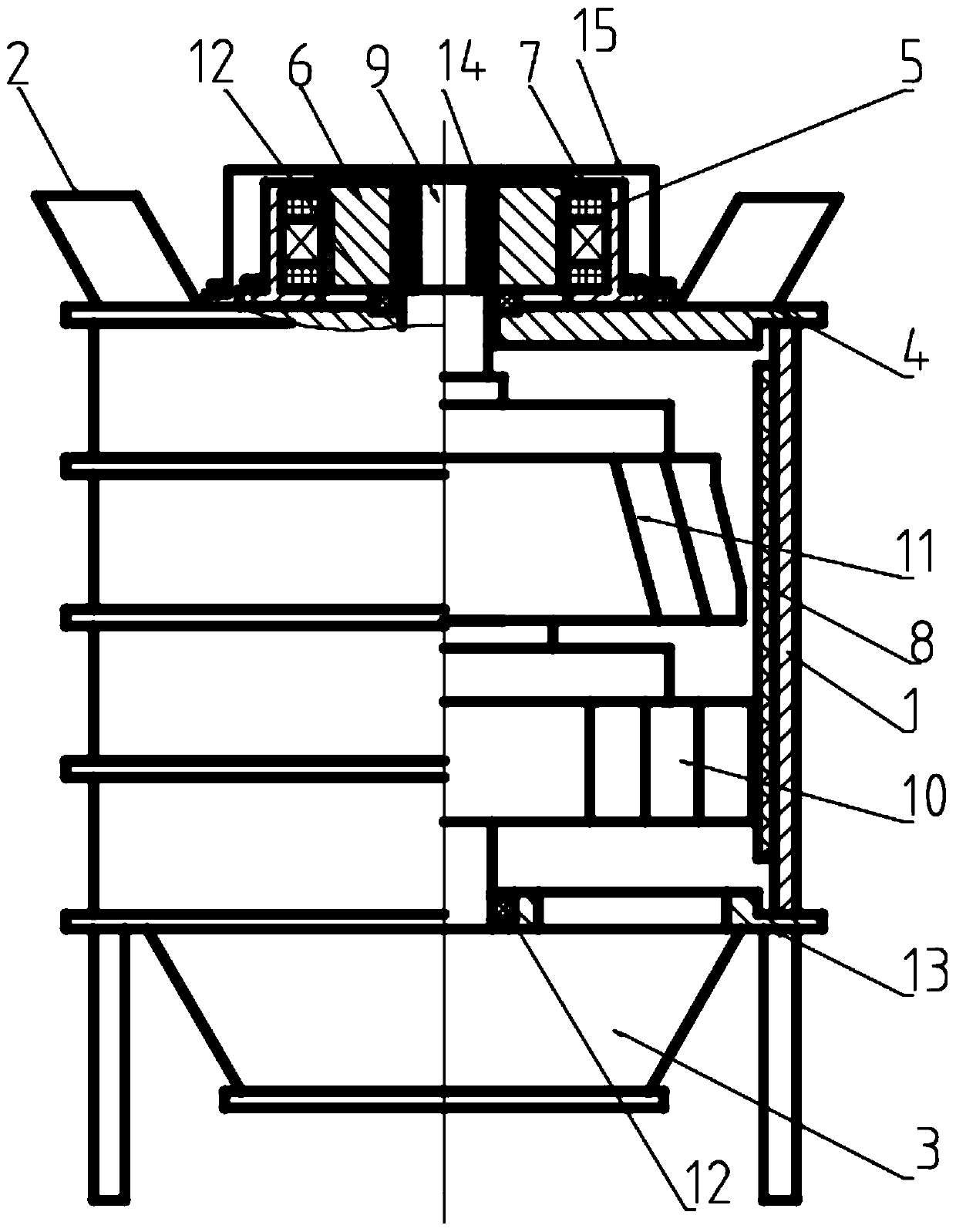

[0036] A compound crusher directly driven by a permanent magnet synchronous motor in this embodiment, combined with Figure 1 to Figure 4 Be explained:

[0037] A compound crusher directly driven by a permanent magnet synchronous motor, comprising a cylinder body 1, a plurality of feed ports 2 are arranged above the cylinder body, and the plurality of feed ports are evenly arranged on a machine cover 4 in a ring around the motor; A discharge port 3 is provided under the cylinder body 1; a lining plate 8 is provided on the inner wall of the cylinder body 1, and the lining plate 8 is a high-strength steel tooth plate; the cylinder body 1 is provided with a main shaft 9 whose rotation axis extends up and down, and the main shaft 9 is provided with two rotors, the gap between the outer end of the lower rotor 10 and the lining plate is smaller than the gap between the outer end of the upper rotor 11 and the lining plate 8; The above permanent magnet synchronous motor 5 is directly...

Embodiment 2

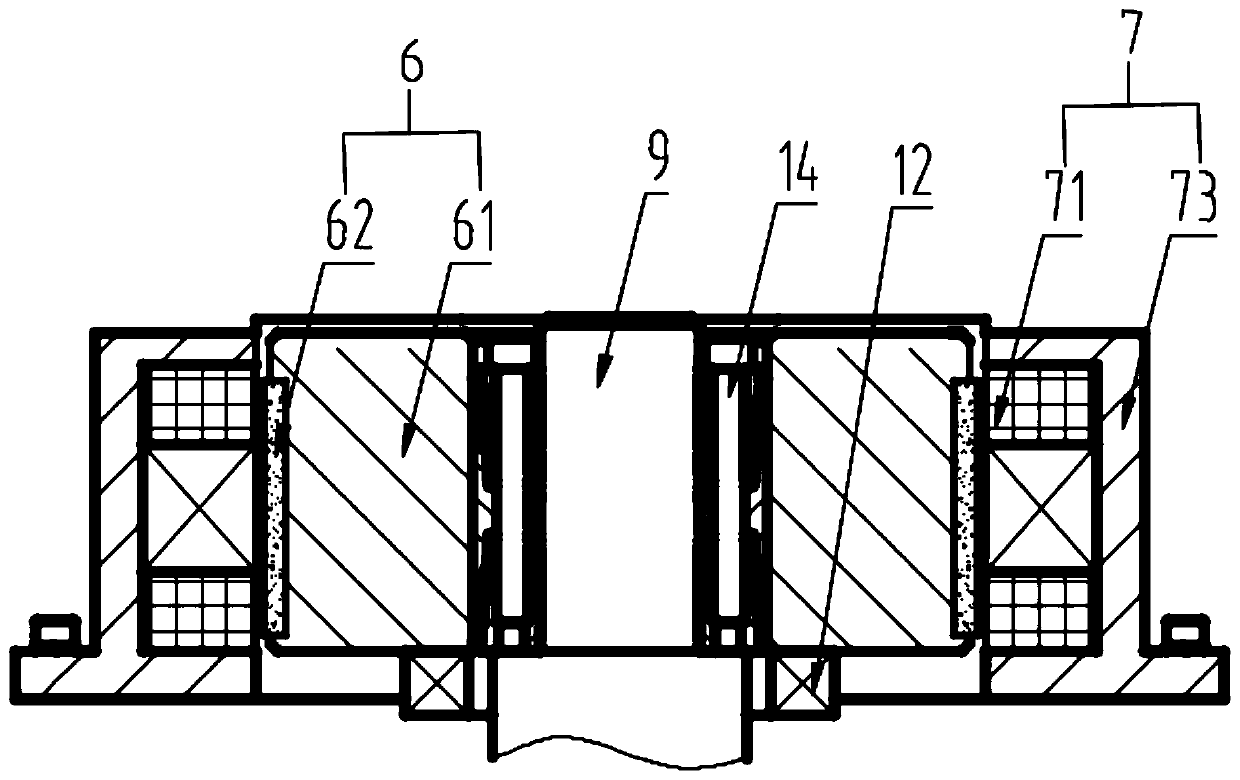

[0043] This embodiment is basically the same as Embodiment 1, and the differences are combined Figure 5 ~ Figure 8 To illustrate: the permanent magnets include two groups of permanent magnets 1 62 and 2 63 on the outer end surface of the rotor base 61 respectively; The first stator base 73 and the second stator base 74 are sleeved, and the first stator base 73 and the second stator base 74 are respectively provided with the stator core of the annular column stator core 71 and the annular disk. Two 72, the first stator base 73 is fixed on the machine cover by bolts, and the second stator base 74 is fixed on the first stator base 73 by bolts.

[0044] After electrification, stator core 1 71 provides a radially rotating magnetic field for permanent magnet 1 62, while stator core 2 72 provides an axially rotating magnetic field for permanent magnet 2 63, prompting stator assembly 7 to provide rotor assembly 6 with The moment of rotation around the axis of the main shaft 9 direct...

Embodiment 3

[0047] This embodiment is basically the same as Embodiment 2, and the differences are combined Figure 9-10 To illustrate: the liner 8 is composed of a plurality of I-shaped high-manganese steel plates that are integrally processed and formed. The I-shaped liner includes a connecting block in the middle and counter-attacking blocks with sharp ends at both ends.

[0048] The liner 8 is installed inside the barrel through a fixing frame 16, the fixing frame 16 includes an upper fixing ring 161 and a lower supporting frame 162, and the upper fixing ring is provided with a plurality of holes for fixing one end of the I-shaped liner 8. Socket, the lower support frame is used to support the bottom surface of the I-shaped liner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com