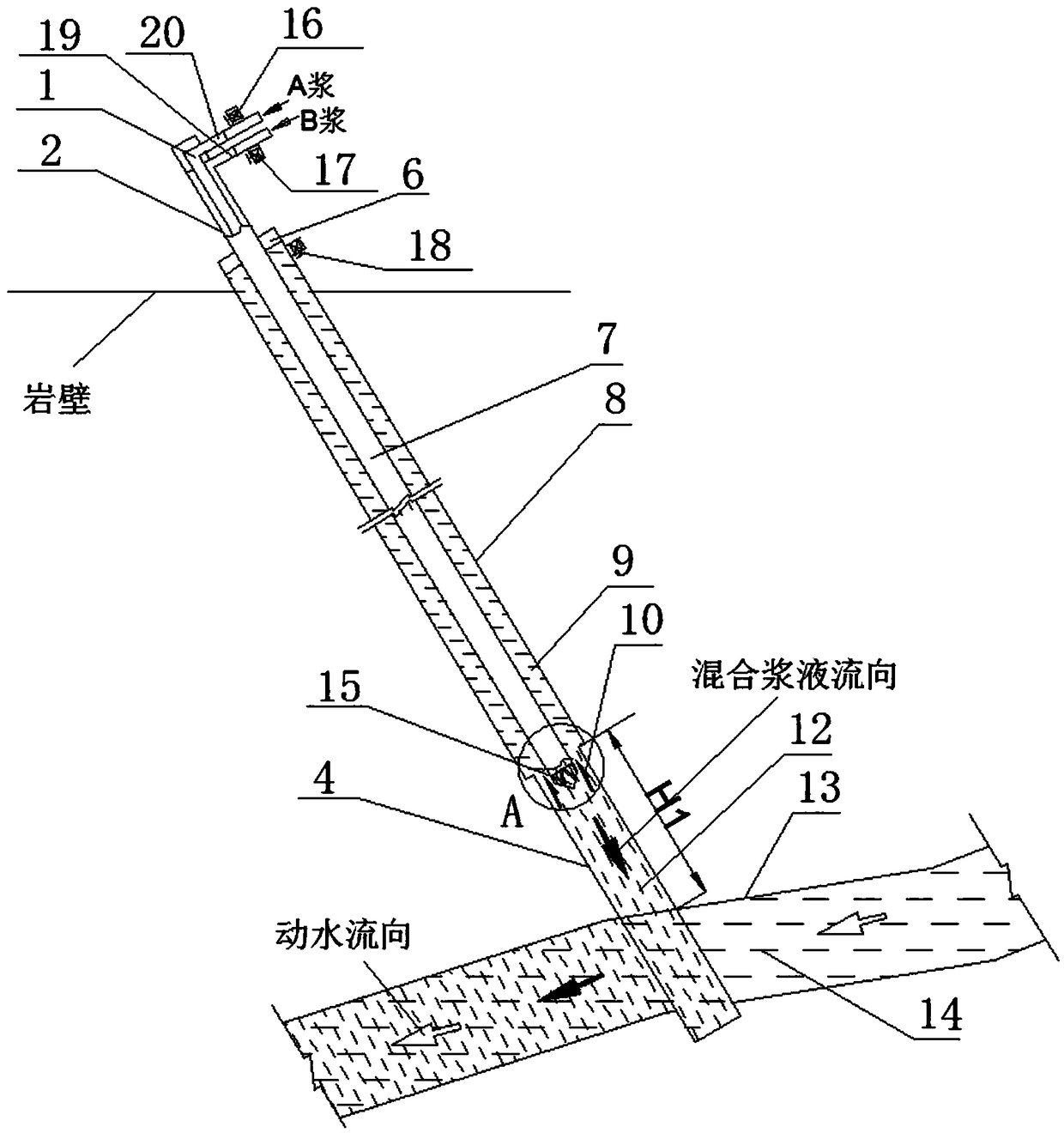

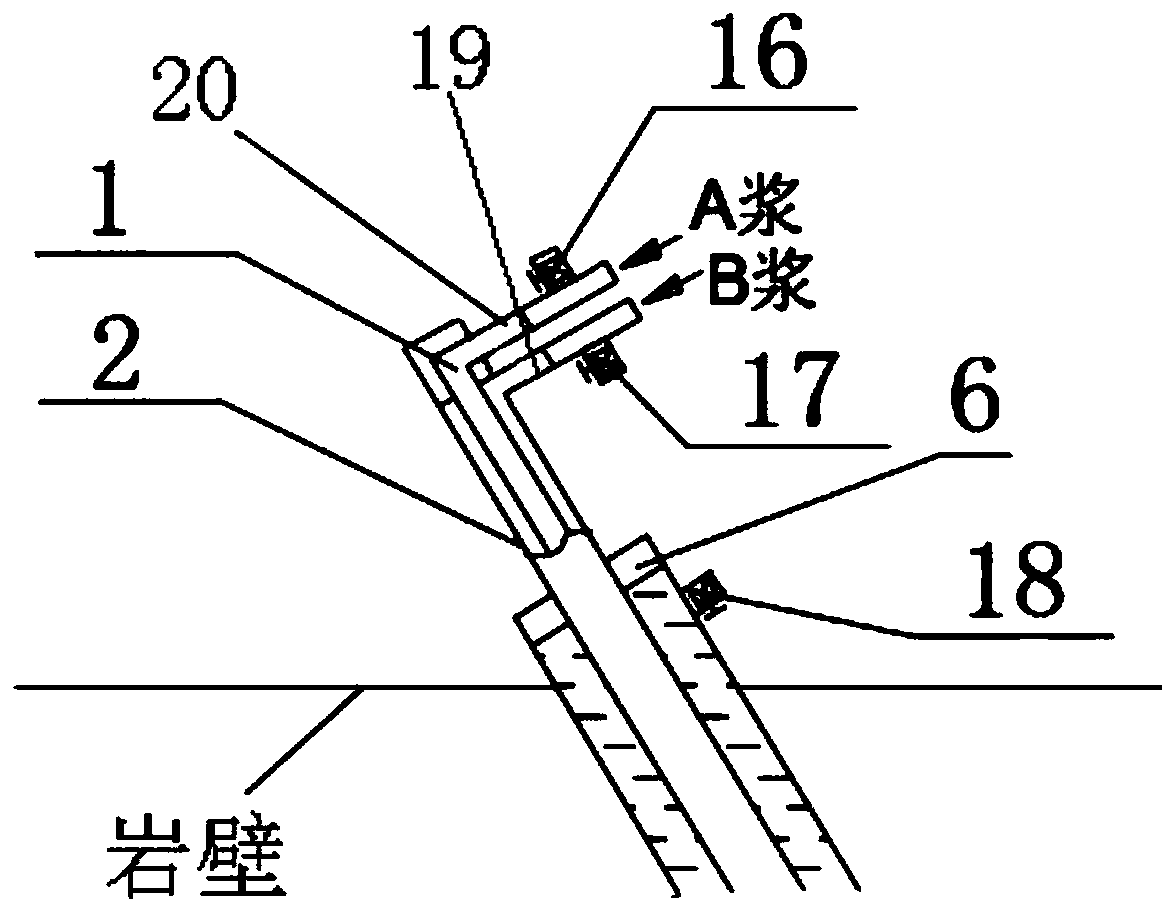

Double-liquid grouting method utilizing water column to stop grout in ultra-deep borehole under mine

A double-fluid grouting and in-drilling technology, which is applied in wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve problems such as long construction period, project cost exceeding budget, and poor grouting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0070]A coal mine in a certain city mines 13 layers of coal in the Taiyuan Formation. The first mining face 41301 is 84m long and the mining elevation is -528m to -496m. On October 11, when the working face was pushed to 110m, there was slight water seepage on the bottom plate (-519m elevation) at 10m west of the ash hole in the outer section of the return air lane of the working face, and then the water volume gradually increased and stabilized at 20m 3 / h. At 19:00 on the 11th, another gushing water appeared west of the return air outlet of the mining face (-503m elevation), and the water volume increased from the initial 5m 3 / h increases gradually. By the 15th, the maximum amount of water gushing up to 230m 3 / h, after the water volume stabilizes at 170m 3 / h. The situation was very critical, and all the workers in the working face were evacuated. The face was flooded due to insufficient drainage capacity of the working face. In order to ensure the safety of the mine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com