Composite additive promoting recovery of iron and aluminum in red mud as well as preparation method and using method of composite additive

A compound additive and aluminum recovery technology, applied in the direction of improving process efficiency, can solve the problems of cumbersome process, low recovery efficiency, high recovery cost, etc., and achieve the effects of simplifying the extraction process, facilitating recovery, and improving the quality of pellets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

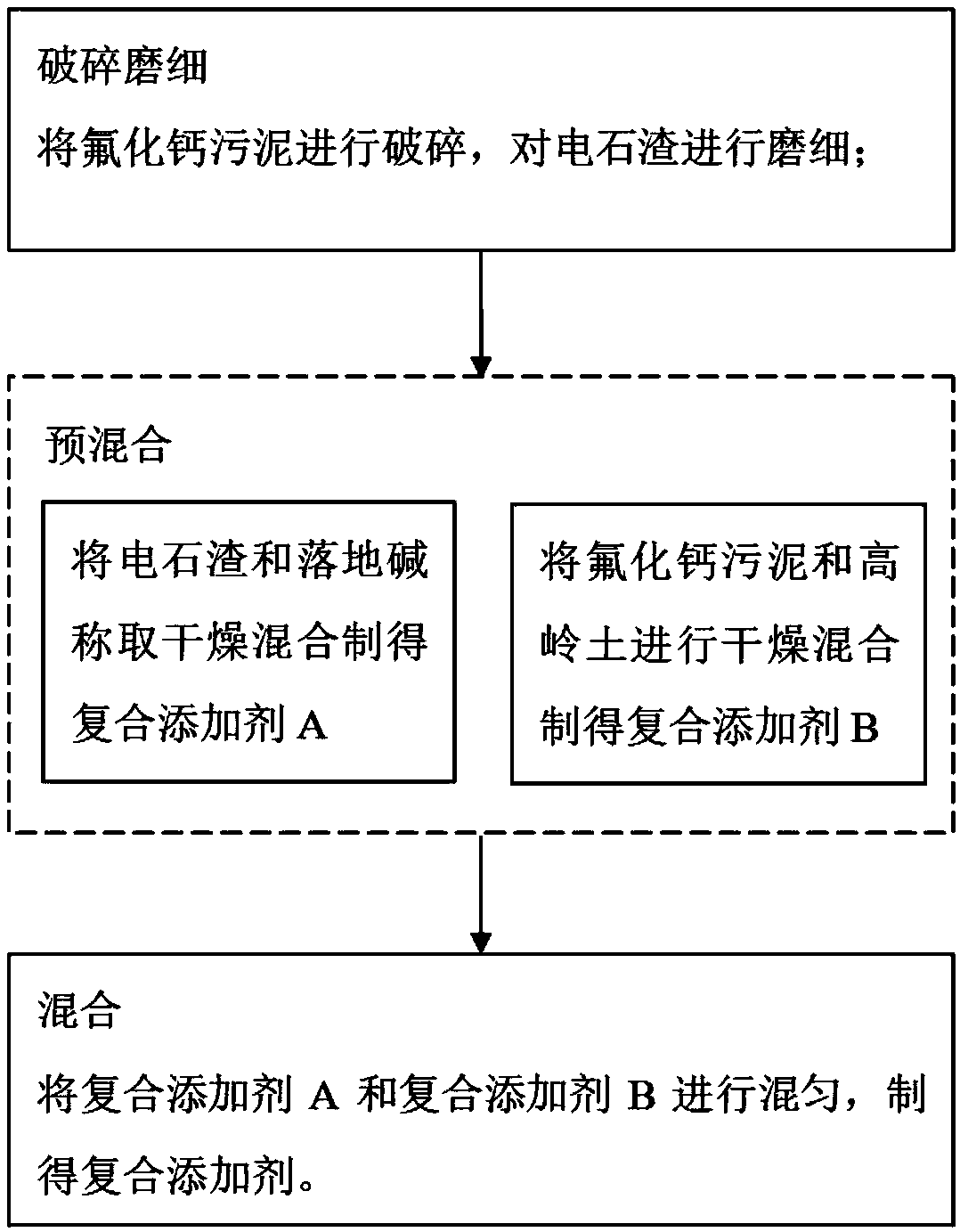

[0043] A composite additive for promoting recovery of red mud, iron and aluminum in this embodiment includes calcium fluoride sludge, kaolin, carbide slag and ground soda. The above components are composed according to the following mass parts in the composite additive: 20-50 parts of calcium fluoride sludge, 5-10 parts of kaolin, 40-70 parts of carbide slag, and 50-80 parts of ground alkali.

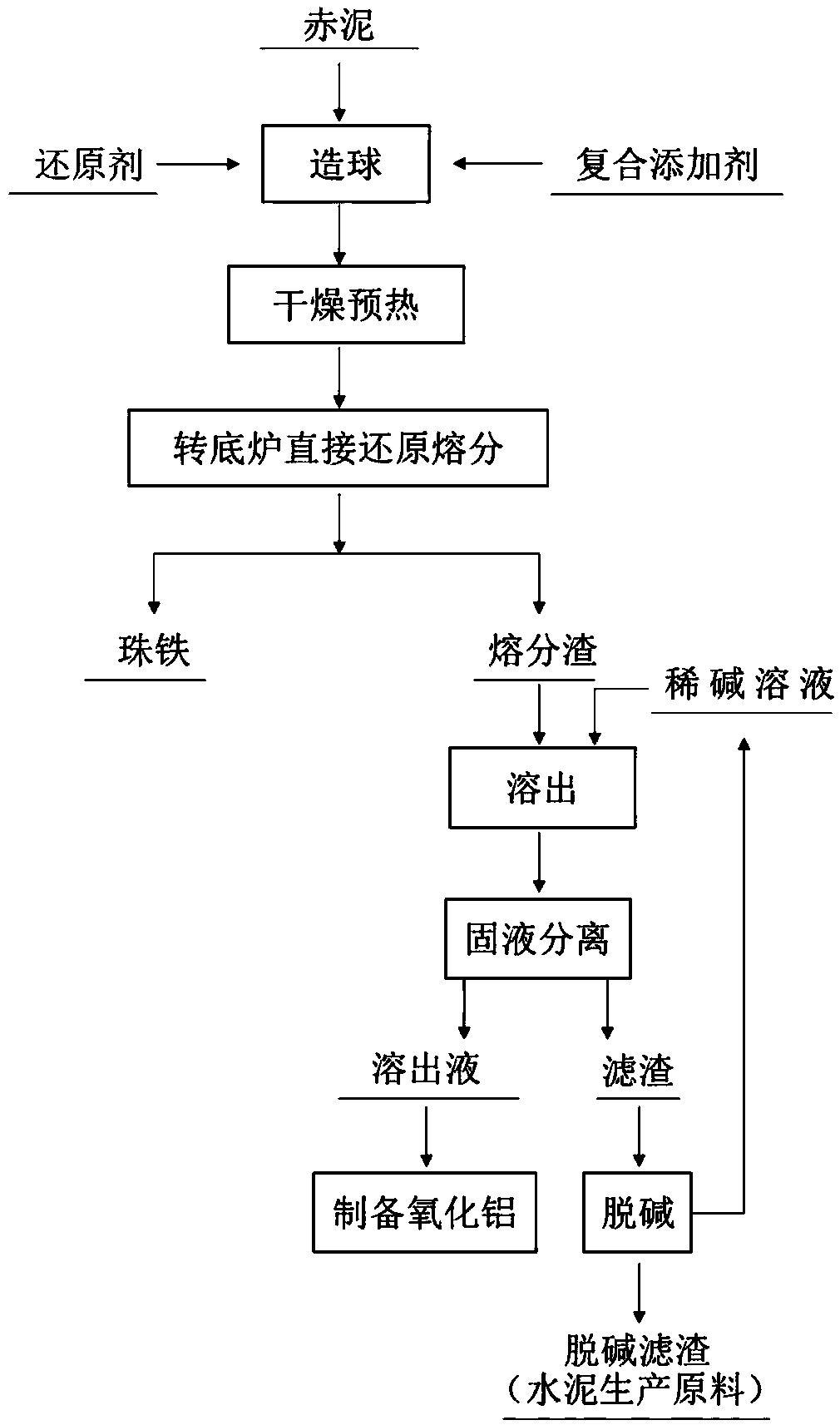

[0044] combine figure 1 As shown, a method for recovering iron and aluminum in red mud by using waste resources in this embodiment, the steps are: mixing red mud, reducing agent and composite additives to pelletize and then performing direct reduction and melting, wherein the composite additives include calcium fluoride Sludge, and then get pearl iron and molten slag after separation of slag and iron, and then use alkali solution to leach molten slag to obtain eluate and filter residue, and use the above eluate to produce alumina. The specific steps are:

[0045] The first step: makin...

Embodiment 2

[0071] This embodiment is basically the same as that of Example 1, except that the composite additive of this embodiment also includes sodium humate, and the amount of sodium humate added is 5 to 10 parts. In this embodiment, sodium humate is 8 servings. The red mud added with compound additives is used to prepare green balls, dry the green balls, and then perform direct reduction melting to obtain iron beads and molten slag; the molten slag is then leached with alkali solution, and then solid-liquid separation The eluate and filter residue are obtained, and aluminum hydroxide is precipitated from the eluate.

[0072] Detect the recovery of this embodiment to obtain the iron grade, iron recovery rate and aluminum dissolution rate of the direct reduction iron beads; the test results are as follows: the iron grade of the iron beads is 90.24%, the iron recovery rate is 94.63%, and the molten slag aluminum dissolution rate is 73.36%. %. The recovery efficiency of straight iron a...

Embodiment 3

[0074] This example is basically the same as Example 1, except that the amount of reducing agent added is 20% of the mass of red mud; the components of the composite additive are: 50 parts of calcium fluoride sludge, 5 parts of kaolin, and 65 parts of carbide slag , 80 parts of ground alkali; wherein calcium oxide content ≥ 68% in calcium carbide slag, calcium fluoride sludge calcium fluoride content is 61%, sodium carbonate content in ground alkali is 62%; present embodiment drying temperature 1000 ℃, drying time 20min; after drying, go to the rotary hearth furnace to directly reduce the melting, the reduction temperature is 1350-1450°C, and the reduction time is 35-50min. The reduction temperature of this embodiment is 1400°C, and the reduction time is 43min; the sodium hydroxide alkali solution of this embodiment The concentration is 15%.

[0075] Detect the recovery of this embodiment to obtain the iron grade, iron recovery rate and aluminum dissolution rate of the direct ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com