Genetic engineering strain of L-aspartic acid-alpha-decarboxylase and application

A genetically engineered strain, aspartic acid technology, applied in the field of genetic engineering, can solve the problems of low enzyme activity, difficult product separation and purification, and low yield of β-alanine biosynthesis, and achieve the effect of increasing product concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The construction of embodiment 1 L-aspartic acid α-decarboxylase genetically engineered bacteria

[0034] Using the L-aspartic acid-α-decarboxylase gene derived from the wild-type Tribulus chinensis as shown in SEQ ID NO.4 as a template, primers were designed:

[0035] For F49, the sequence information is shown in SEQ ID NO 7; for R49, the sequence information is shown in SEQ ID NO 8.

[0036] For F369, the sequence information is shown in SEQ ID NO 9; for R369, the sequence information is shown in SEQ ID NO 10.

[0037] For F221, the sequence information is shown in SEQ ID NO 11; for R221, the sequence information is shown in SEQ ID NO 12.

[0038] Use the whole plasmid PCR method to obtain the plasmid in which the mutated gene is connected to the expression vector pET 28a(+), digest it with DpnI for about 3 hours, and transfer it into Escherichia coli JM109 by competent heat stimulation. The plasmids were extracted overnight and sent to the sequencing company for se...

Embodiment 2

[0039] The cultivation, induction and expression of embodiment 2 L-aspartic acid α-decarboxylase genetically engineered bacteria

[0040]The obtained wild-type and mutant aspartate-a decarboxylase engineered bacteria were inoculated into 5 mL of LB medium with a kanamycin concentration of 50 μg / mL, and cultured overnight at 37° C. with shaking at 200 r / min. The above culture was inoculated into 2xYT medium with a kanamycin concentration of 50 μg / mL at an inoculum size of 1%, and cultured with shaking at 37°C and 200 r / min until OD 600 0.6–0.8, add a final concentration of 0.2mmol / L IPTG, culture at 20°C for 16–20h, and collect the bacteria by centrifugation at 4000rpm.

Embodiment 3

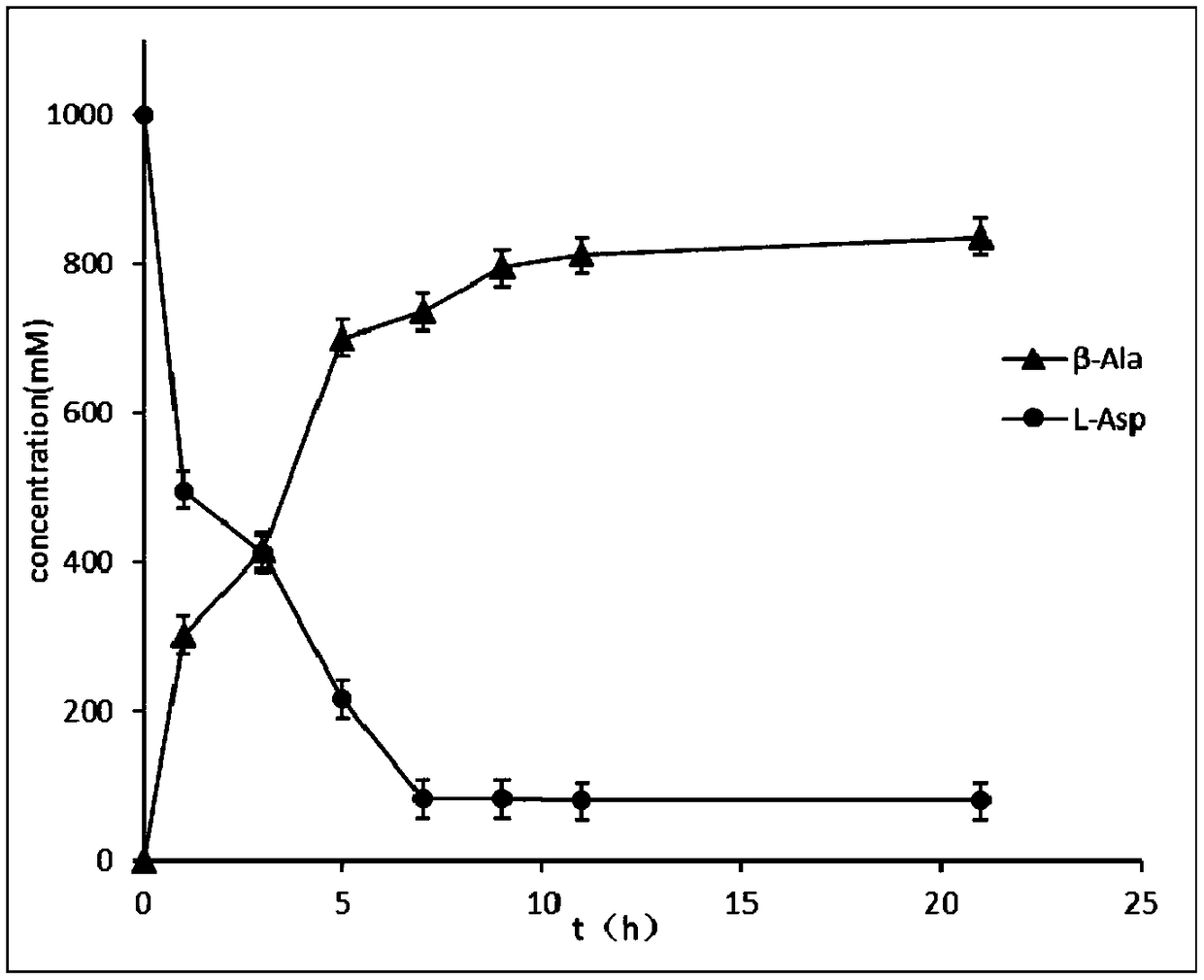

[0041] The catalytic process of embodiment 3 one-time addition of high-concentration solid substrate

[0042] After the induced strain was collected by centrifugation, the whole cell catalytic reaction was carried out. Cell OD 600 200, pH 6.5, PLP concentration 1mmol / L, reaction temperature 37°C, add solid substrate L-sodium aspartate at one time to a final concentration of 1mol / L. Samples were taken at regular intervals to detect the amount of β-alanine produced. The result is as figure 1 shown. After 23 hours of conversion, 836 mmol / L of β-alanine was produced, and the molar conversion rate was 83.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com