Method and device for cutting Fischer-Tropsch synthesis light oil with dividing wall columns

A tower cutting fee and Fischer-Tropsch synthesis technology, which is applied in the petroleum industry, processing hydrocarbon oil, hydrocarbon distillation, etc., can solve the problems of complex process, high energy consumption and equipment cost, and difficult to use products carefully.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

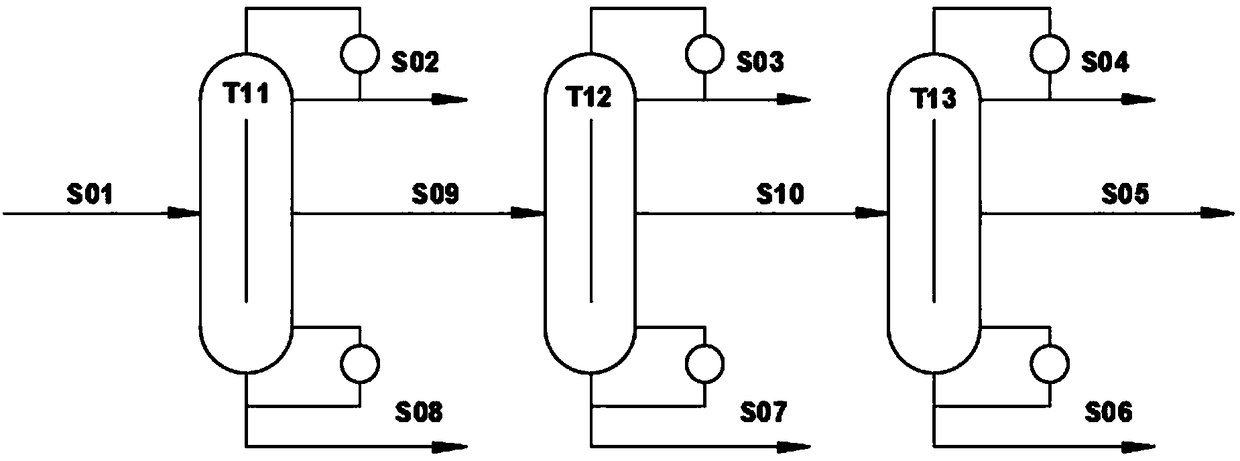

Embodiment 1

[0044] Applying the invention to a narrow fraction cut process for Fischer-Tropsch synthetic light oils, such as Picture 1-1 As shown, including the first single dividing wall column (T11), the second single dividing wall column (T12), the third single dividing wall column (T13), condenser, reboiler, pump and related feed lines and connection of the above equipment pipeline. The raw material is 1000g Fischer-Tropsch synthetic oil light oil, which contains hydrocarbons in the range of C6-C10 and trace amounts of oxygen-containing compounds. The hydrocarbons mainly include normal alkanes and α-olefins, and also include some isoparaffins, internal olefins, branched olefins, and a small amount of cycloalkanes, aromatics, and cycloolefins. Oxygenated compounds include one or more of alcohols, aldehydes, ketones, acids, and esters. The first single partition tower (T11) pre-separation tower ( Pic 4-1 The number of theoretical plates in the area a) is 10, and the main tower ( P...

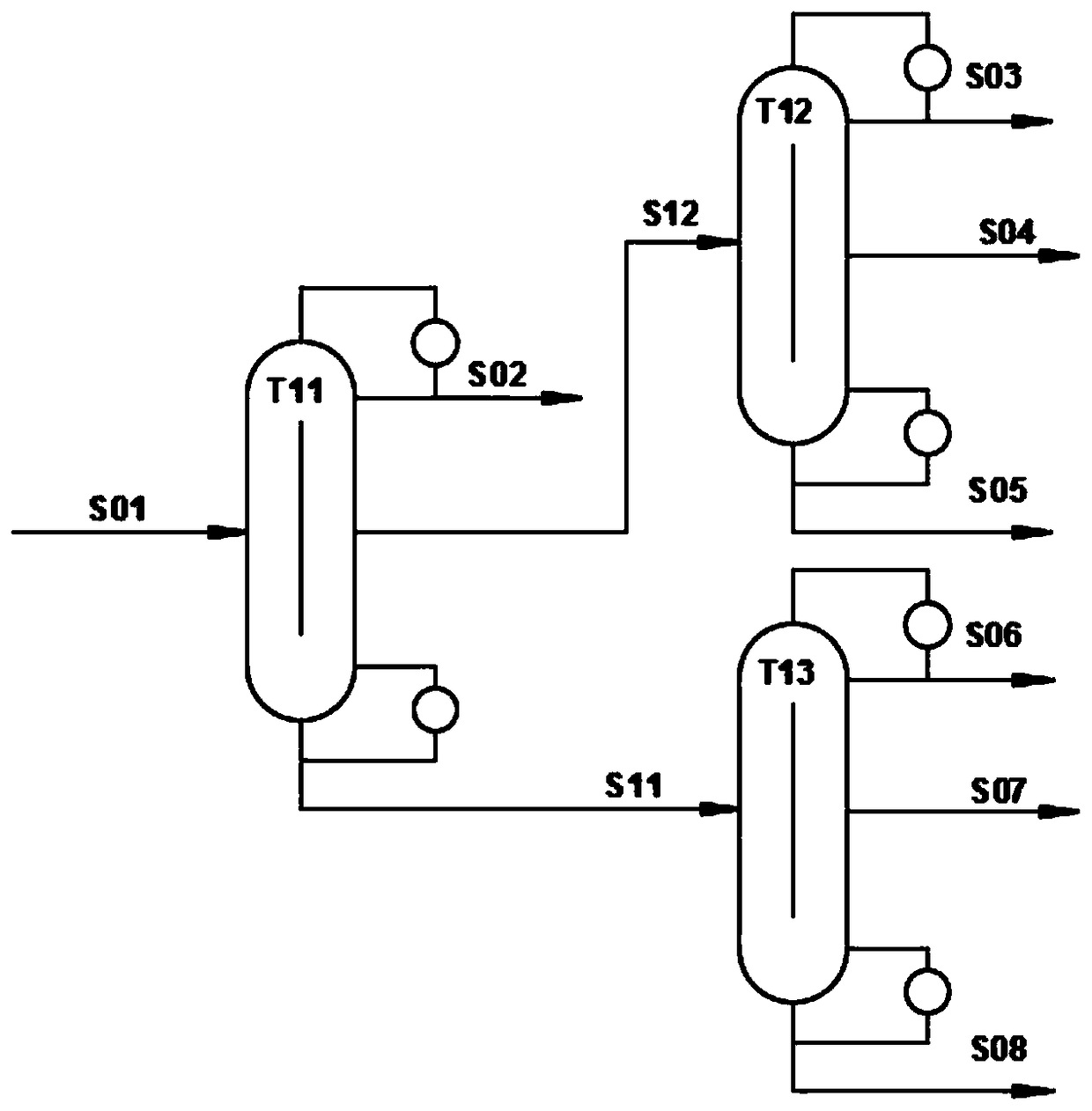

Embodiment 2

[0046] Applying the invention to a narrow fraction cut process for Fischer-Tropsch synthetic light oils, such as diagram 2-1 As shown, it includes the first double dividing wall column (T21), the second double dividing wall column (T22), condenser, reboiler, pump and related feed lines and pipelines connecting the above equipment. The raw material is 1000g Fischer-Tropsch synthetic oil light oil, which contains hydrocarbons in the range of C6-C10 and trace amounts of oxygen-containing compounds. The hydrocarbons mainly include normal alkanes and α-olefins, and also include some isoparaffins, internal olefins, branched olefins, and a small amount of cycloalkanes, aromatics, and cycloolefins. Oxygenated compounds include one or more of alcohols, aldehydes, ketones, acids, and esters. The pre-separation tower ( Figure 4-2 The number of theoretical plates in the e region) is 10, and the first main column ( Figure 4-2 The f area in) theoretical plate number is 200, the first ...

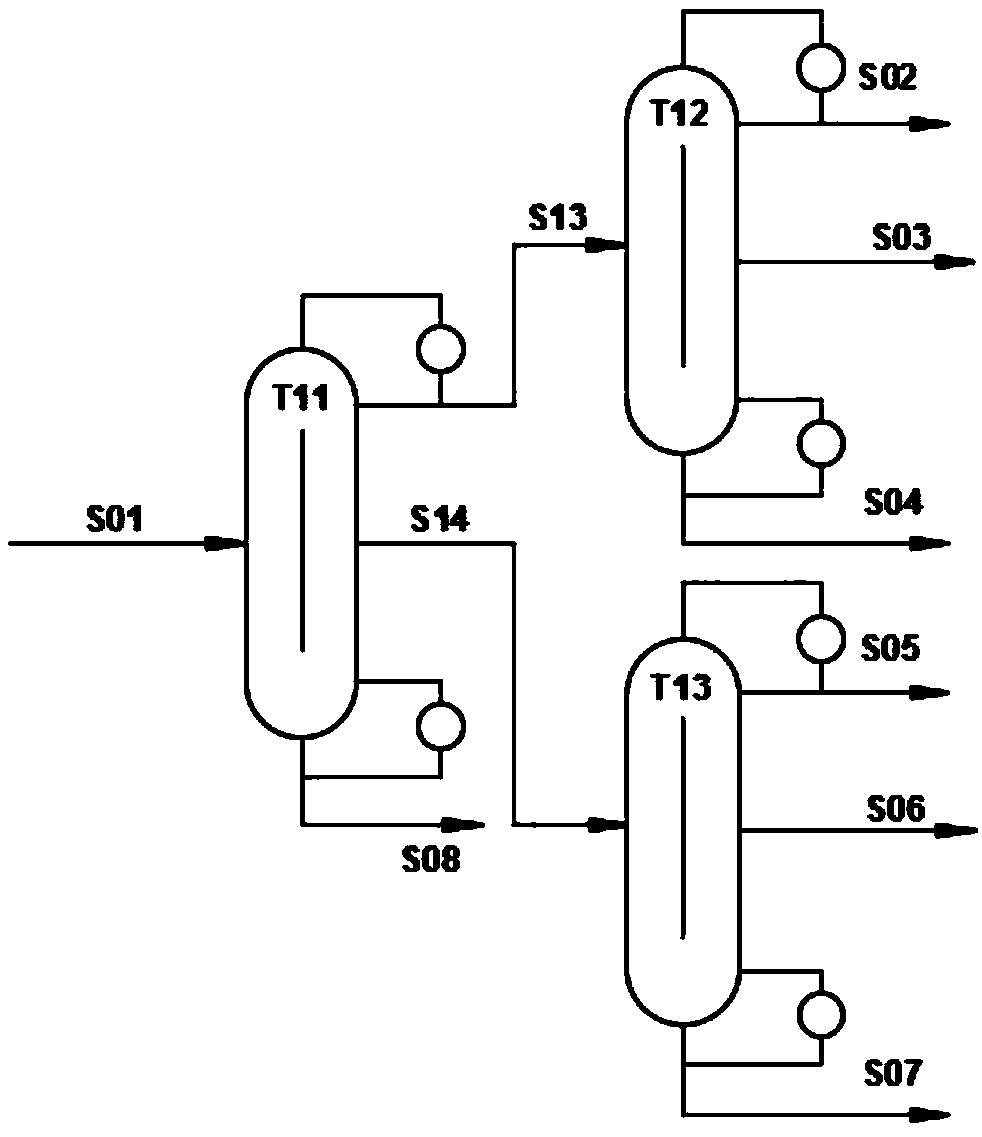

Embodiment 3

[0048] Applying the invention to a narrow fraction cut process for Fischer-Tropsch synthetic light oils, such as image 3 As shown, including five dividing wall columns (T3), condenser, reboiler, pump and related feed lines and pipelines connecting the above equipment. The raw material is 1000g Fischer-Tropsch synthetic oil light oil, which contains hydrocarbons in the range of C6-C10 and trace amounts of oxygen-containing compounds. The hydrocarbons mainly include normal alkanes and α-olefins, and also include some isoparaffins, internal olefins, branched olefins, and a small amount of cycloalkanes, aromatics, and cycloolefins. Oxygenated compounds include one or more of alcohols, aldehydes, ketones, acids, and esters. The pre-separation tower ( Figure 4-3 1 area in) the number of theoretical plates is 200, the first main column ( Figure 4-3 2 areas in) the number of theoretical plates is 10, the first public rectification section ( Figure 4-3 3 areas in) the number of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com